Abstract

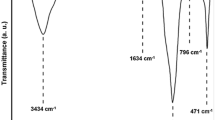

Mesoporous diatomite was employed to synthesize different poly (methyl methacrylate)/diatomite composites. Diatomite platelets were used for in situ polymerization of methyl methacrylate by RATRP to synthesize tailor-made poly (methyl methacrylate) nanocomposites. FTIR spectroscopy, TGA, nitrogen adsorption/desorption isotherm, SEM, and TEM were employed for evaluating some inherent properties of pristine diatomite platelets. Conversion and molecular weight determinations were carried out using GC and SEC, respectively. Addition of 3 wt% pristine mesoporous diatomite leads to increase of conversion from 84 to 95%. Molecular weight of poly (methyl methacrylate) chains increases from 8600 to 9400 g mol−1 by addition of 3 wt% pristine mesoporous diatomite; however, polydispersity index values increase from 1.34 to 1.54. Increasing thermal stability of the nanocomposites is demonstrated by TGA. Differential scanning calorimetry shows an increase in glass transition temperature from 75.8 to 81.1 °C by adding 3 wt% of mesoporous diatomite platelets.

Similar content being viewed by others

References

Brown JM, Curliss D, Vaia RA (2000) Thermoset-layered silicate nanocomposites. Quaternary ammonium montmorillonite with primary diamine cured epoxies. Chem Mater 12:3376–3384

Mirzataheri M, Mahdavian AR, Atai M (2009) Nanocomposite particles with core-shell morphology IV: an efficient approach to the encapsulation of Cloisite 30B by poly (styrene-co-butyl acrylate) and preparation of its nanocomposite latex via miniemulsion polymerization. Coll Polym Sci 287:725–732

Fazli Y, Kulani E, Khezri K, Alijani H (2015) PMMA-grafted silica aerogel nanoparticles via in situ SR&NI ATRP: grafting through approach. Micropor Mesopor Mater 214:70–79

Khezri K, Mahdavi H (2016) Reverse atom transfer radical polymerization of styrene in the presence of functionalized silica aerogel nanoparticles. Z Phys Chem 230:1499–1518

Burkett SL, Ko N, Stern ND, Caissie JA, Sengupta D (2006) Covalently linked nanocomposites: poly(methyl methacrylate) brushes grafted from zirconium phosphonate. Chem Mater 18:5137–5143

Roghani-Mamaqani H, Khezri K (2016) Polystyrene-attached graphene nanolayers by reversible addition-fragmentation chain transfer polymerization: a grafting from epoxy groups with various densities. J Polym Res 23:190–204

Khezri K, Fazli Y (2016) Synthesis and characterization of poly (styrene-co-butyl acrylate)/silica aerogel nanocomposites by in situ AGET ATRP: investigating thermal properties. High Temp Mater Proc. doi:10.1515/htmp-2015-0244

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng 28:1–63

Fazli Y, Alijani H, Khezri K (2016) Styrene and methyl methacrylate random copolymerization via AGET ATRP: incorporation of hydrophobic silica aerogel nanoparticles. Adv Polym Technol 35:21549–21557

Varghese S, Karger-Kocsis J (2003) Natural rubber-based nanocomposites by latex compounding with layered silicates. Polymer 44:4921–4927

Khezri K, Haddadi-Asl V, Roghani-Mamaqani H, Salami-Kalajahi M (2012) Synthesis of clay-dispersed poly(styrene-co-methyl methacrylate) nanocomposite via miniemulsion atom transfer radical polymerization: a reverse approach. J Appl Polym Sci 124:2278–2286

Pyun J, Matyjaszewski K (2001) Synthesis of nanocomposite organic/inorganic hybrid materials using controlled/“living” radical polymerization. Chem Mater 13:3436–3448

Yu Y, Addai-Mensah J, Losic D (2012) Functionalized diatom silica microparticles for removal of mercury ions. Sci Technol Adv Mater 13:015008 (11pp)

Ha J, Oh E, Song I (2013) The fabrication and characterization of sintered diatomite for potential microfiltration applications. Ceram Int 39:7641–7648

Caliskan N, Kul AR, Alkan S, Sogut EG, Alacabey I (2011) Adsorption of zinc(II) on diatomite and manganese-oxide-modified diatomite: a kinetic and equilibrium study. J Hazard Mater 193:27–36

Gerengi H, Kocak Y, Jazdzewska A, Kurtay M, Durgun H (2013) Electrochemical investigations on the corrosion behaviour of reinforcing steel in diatomite- and zeolite-containing concrete exposed to sulphuric acid. Construc Build Mater 49:471–477

Sun Z, Zheng S, Ayoko GA, Frost RL, Xi Y (2013) Degradation of simazine from aqueous solutions by diatomite-supported nanosized zero-valent iron composite materials. J Hazard Mater 263:768–777

Yu Z, Wang Y, Liu X, Sun J, Sha G, Yang J, Meng C (2014) A novel pathway for the synthesis of ordered mesoporous silica from diatomite. Mater Let 119:150–153

Posi P, Lertnimoolchai S, Sata V, Chindaprasirt P (2013) Pressed lightweight concrete containing calcined diatomite aggregate. Construc Build Mater 47:896–901

Zhang Y, Zhao Y, Chu H, Zhou X, Dong B (2014) Dewatering of Chlorella pyrenoidosa using diatomite dynamicmembrane: filtration performance, membrane fouling andcake behavior. Coll Surf B: Biointerfaces 113:458–466

Ruggiero I, Terracciano M, Martucci NM, De Stefano L, Migliaccio N, Tatè R, Rendina I, Arcari P, Lamberti A, Rea I (2014) Diatomite silica nanoparticles for drug delivery. Nanoscale Res Let 9:329–336

Nenadovic S, Nenadovic M, Kovacevic R, Matovic L, Matovic B, Jovanovic Z, Grbovic Novakovic J (2009) Influence of diatomite microstructure on its adsorption capacity for Pb(II). Sci Sintering 41:309–317

Shen W, Feng L, Lei A, Liu Z, Chen Y (2014) Effects of porosity and pore size on the properties of AgO-decorated porous diatomite ceramic composites. Ceram Int 40:1495–1502

Zetterlund PB, Kagawa Y, Okubo M (2008) Controlled/living radical polymerization in dispersed systems. Chem Rev 108:3747–3794

Khezri K, Alijani H, Fazli Y (2016) Activators regenerated by electron transfer for atom transfer radical polymerization of styrene in the presence of hydrophobically modified silica aerogel nanoparticles. Z Phys Chem 230:111–129

Yi Z, Pan K, Jiang L, Zhang J, Dan Y (2007) Copper-based reverse ATRP process of styrene in mixed solvents. Europ Polym J 43:2557–2563

Braunecker W, Matyjaszewski K (2007) Controlled/living radical polymerization: features, developments, and perspectives. Prog Polym Sci 32:93–146

Yu Z-Q, Ji X-L, Ni P (2006) Living radical miniemulsion polymerization by RAFT in the presence of beta-cyclodextrin. Coll Polym Sci 285:211–218

Hawker CJ, Bosman AW, Harth E (2001) New polymer synthesis by nitroxide mediated living radical polymerizations. Chem Rev 101:3661–3688

Wang Y, Zhang Y, Hou C, He X, Liu M (2016) Preparation of a novel TETA functionalized magnetic PGMA nano-absorbent by ATRP method and used for highly effective adsorption of Hg(II). J Taiwan Inst Chem Eng 58:283–289

Roghani-Mamaqani H, Khezri K (2016) A grafting from approach to graft polystyrene chains at the surface ofgraphene nanolayers by RAFT –hydroxyl groups. Appl Surf Sci 360:373–382

Khezri K, Mahdavi H (2016) Polystyrene-silica aerogel nanocomposites by in situ simultaneous reverse and normal initiation technique for ATRP. Micropo Mesopor Mater 228:132–140

Cheng Z, Zhu X, Zhang L, Zhou N, Chen J (2003) Homogeneous solution reverse atom transfer radical polymerization of methyl methacrylate. J Macromol Sci Part A-Pure and Applied Chemistry A40:371–385

Karaman S, Karaipekli A, Sarı A, Bicer A (2011) Polyethylene glycol (PEG)/diatomite composite as a novel form-stable phase change material for thermal energy storage. Solar Energy Mater Solar Cells 95:1647–1653

Li X, Bian C, Chen W, He J, Wang Z, Xu N, Xue G (2003) Polyaniline on surface modification of diatomite: a novel way to obtain conducting diatomite fillers. Appl Surf Sci 207:378–383

Li X, Li X, Wang G (2005) Fibrillar polyaniline/diatomite composite synthesized by one-step in situ polymerization method. Appl Surf Sci 249:266–270

Hu S, Zhu X, Hu W, Yan L, Cai C (2013) Crystallization behaviors and foaming properties of diatomite-filled polypropylene composites. Polym Bull 70:517–533

Liang JZ (2008) Effects of extrusion conditions on die-swell behavior of polypropylene/diatomite composite melts. Polym Tes 27:936–940

Sheng G, Dong H, Li Y (2012) Characterization of diatomite and its application for the retention of radiocobalt: role of environmental parameters. J Environ Radioact 113:108–115

Yuan P, Liu D, Tan D, Liu K, Yu H, Zhong Y, Yuan A, Yu W, He H (2013) Surface silylation of mesoporous/macroporous diatomite (diatomaceous earth) and its function in Cu(II) adsorption: the effects of heating pretreatment. Micropors Mesopor Mater 170:9–19

Garderen N, Clemens FJ, Mezzomo M, Bergmann CP, Graule T (2011) Investigation of clay content and sintering temperature on attrition resistance of highly porous diatomite based material. Appl Clay Sci 52:115–121

Du Y, Yan J, Meng Q, Wang J, Dai H (2012) Fabrication and excellent conductive performance of antimony-doped tin oxide-coated diatomite with porous structure. Mater Chem Phys 133:907–912

Sun Z, Yang X, Zhang G, Zheng S, Frost RL (2013) A novel method for purification of low grade diatomite powders in centrifugal fields. Int J Miner Process 125:18–26

Liu D, Yuan P, Tan D, Liu H, Wang T, Fan M, Zhu J, He H (2012) Facile preparation of hierarchically porous carbon using diatomite as both template and catalyst and methylene blue adsorption of carbon products. J Coll Interf Sci 388:176–184

Xia J, Matyjaszewski K (1997) Controlled/“living” radical polymerization. Homogeneous reverse atom transfer radical polymerization using AIBN as the initiator. Macromolecules 30:7692–7696

Li M, Matyjaszewski K (2003) Reverse atom transfer radical polymerization in miniemulsion. Macromolecules 36:6028–6035

Roghani-Mamaqani H, Haddadi-Asl V, Najafi M, Salami-Kalajahi M (2010) Synthesis and characterization of clay dispersed polystyrene nanocomposite via atom transfer radical polymerization. Polym Compos 31:1829–1837

-Asfadeh A, Haddadi-Asl V, Salami-Kalajahi M, Sarsabili M, Roghani-Mamaqani H (2013) Investigating the Effect of MCM-41 Nanoparticles on the Kinetics of Atom Transfer Radical Polymerization of Styrene. NANO 8:Art Number: 1350018

Khezri K (2016) Polystyrene–mesoporous diatomite composites produced by in situ activators regenerated by electron transfer atom transfer radical polymerization. RSC Adv 6:109286–109296

Khezri K, Fazli Y (2016) Characterization of diatomite platelets and its application for in situ atom transfer radical random copolymerization of styrene and butyl acrylate: normal approach. J Inorg Organomet Polym. doi:10.1007/s10904-016-0469-5

Sarsabili M, Kalantari K, Khezri K (2016) SR&NI atom transfer radical random copolymerization of styrene and butyl acrylate in the presence of MPS-functionalized silica aerogel nanoparticles: Investigating thermal properties. J Therm Anal Calorim 126:1261–1272

Subramania S, Choia SW, Lee JY, Kim JH (2007) Aqueous dispersion of novel silylated (polyurethane-acrylic hybrid/clay) nanocomposite. Polymer 48:4691–4703

Ver Meer MA, Narasimhan B, Shanks BH, Mallapragada SK (2010) Effect of Mesoporosity on thermal and mechanical properties of polystyrene/silica composites. ACS Appl Mater Interf 2:41–47

Khezri K, Haddadi-Asl V, Roghani-Mamaqani H, Salami-Kalajahi M (2012) Polystyrene- organoclay nanocomposites produced by in situ activators regenerated by electron transfer for atom transfer radical polymerization. J Polym Eng 32:235–243

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical responsibilities of authors is completely read.

This research received no specific grant from any funding agency in the public or commercial sectors.

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Fazli, Y., Khezri, K. Mesoporous diatomite-filled PMMA by in situ reverse atom transfer radical polymerization. Colloid Polym Sci 295, 247–257 (2017). https://doi.org/10.1007/s00396-016-3997-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-016-3997-1