Abstract

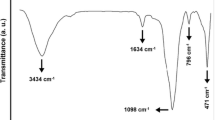

Mesoporous diatomite nanoplatelets were used for in situ polymerization of methyl methacrylate via activators generated by electron transfer for atom transfer radical polymerization to synthesize well-defined poly (methyl methacrylate) nanocomposites. X-ray fluorescence, FTIR spectroscopy and thermogravimetric analysis (TGA) were employed for evaluating some inherent properties of pristine diatomite nanoplatelets. In addition, structural and morphological studies were also performed by nitrogen adsorption/desorption isotherm, SEM and TEM. Conversion and molecular weight determinations were carried out using gas and size exclusion chromatography respectively. Addition of 3 wt% mesoporous diatomite leads to increase of conversion from 75 to 91%. Molecular weight of PMMA chains increases from 7213 to 9878 g.mol−1 by addition of 3 wt% mesoporous diatomite; however, polydispersity index values increases from 1.15 to 1.43. Increasing thermal stability of the nanocomposites is demonstrated by TGA. Differential scanning calorimetry shows an increase in glass transition temperature from 77.3 to 82.4 °C by adding 3 wt% of mesoporous diatomite nanoplatelets.

Similar content being viewed by others

References

Rao Y, Pochan JM (2007). Macromolecules 40:290

Farkhondekalam Ghadim M, Imani A, Farzi G (2014) J Nanostruct Chem 4:101

Hsu Y, Chen G, Lee R (2014). J Polym Res 21:440

Ghobadi E, Hemmati M, Khanbabaei G, Shojaei M, Asghari M (2015) Int J Nano Dimens 6:177

Pourasghar A, Kamarian S (2015) Int J Nano Dimens 6:167

Fu X, Qutubuddin S (2001). Polymer 42:807

Alexandre M, Dubois P (2000). Mater Sci Eng 28:1

Zanetti M, Lomakin S (2000). Macromol Mater Eng 279:1

Varghese S, Karger-Kocsis J (2003). Polymer 44:4921

Sarsabili M, Kalantari K, Khezri K (2016) J Therm Anal Calorim 126:1261

Al-degs Y, Khraisheh MAM, Tutunji MF (2001). Wat Res 35:3724

Ruggiero I, Terracciano M, Martucci NM, De Stefano L, Migliaccio N, Tatè R, Rendina I, Arcari P, Lamberti A, Rea I (2014). Nanoscale Res Lett 9:329

Tsai W, Lai C, Hsien K (2006). J Colloid Interface Sci 297:749

Li X, Li X, Wang G (2007). Mater Chem Phys 102:140

Yu Y, Addai-Mensah J, Losic D (2012). Sci Technol Adv Mater 13:015008

Nenadovic S, Nenadovic M, Kovacevic R, Matovic L, Matovic B, Jovanovic Z, Grbovic Novakovic J (2009). Sci Sint 41:309

Yuan P, Liu D, Tan D, Liu K, Yu H, Zhong Y, Yuan A, Yu W, He H (2013). Microporous Mesoporous Mater 170:9

Caliskan N, Kul AR, Alkan S, Sogut EG, Alacabey I (2011). J Hazard Mater 193:27

Abbasian M, Jaymand M, Ghadami MZ, Fathi A (2010) Int J Nanosci Nanotechnol 6:168

Matyjaszewski K, Xia J (2001). Chem Rev 101:2921

Abbasian M, Khakpour Aali N (2016) J Nanostruct 6:38

Cunningham MF (2008). Prog Polym Sci 33:365

Karaman S, Karaipekli A, Sarı A, Bicer A (2011). Sol Energy Mater Sol Cells 95:1647

Li X, Bian C, Chen W, He J, Wang Z, Xu N, Xue G (2003). Appl Surf Sci 207:378

Li X, Li X, Wang G (2005). Appl Surf Sci 249:266

Hu S, Zhu X, Hu W, Yan L, Cai C (2013). Polym Bull 70:517

Liang JZ (2008). Polym Test 27:936

Sheng G, Dong H, Li Y (2012). J Environ Radioact 113:108

Khezri K, Fazli Y (2017). J Inorg Organomet Polym 27:266

Garderen N, Clemens FJ, Mezzomo M, Bergmann CP, Graule T (2011). Appl Clay Sci 52:115

Du Y, Yan J, Meng Q, Wang J, Dai H (2012). Mater Chem Phys 133:907

Sun Z, Yang X, Zhang G, Zheng S, Frost RL (2013). Int J Miner Process 125:18

Liu D, Yuan P, Tan D, Liu H, Wang T, Fan M, Zhu J, He H (2012). J Colloid Interface Sci 388:176

Li M, Matyjaszewski K (2003). Macromolecules 36:6028

Min K, Gao H, Matyjaszewski K (2005). J Am Chem Soc 127:3825

Zhang L, Cheng Z, Lu Y, Zhu X (2009). Macromol Rapid Commun 30:543

Wu D, Yang Y, Cheng X, Liu L, Tian J, Zhao H (2006). Macromolecules 39:7513

Khezri K (2016) RSC Adv 6:109286

Khezri K, Fazli Y (2017) Polym Sci Ser B 59:109

Fazli Y, Khezri K (2017). Colloid Polym Sci 295:247

Davoudizadeh S, Sarsabili M, Khezri K (2017) Z Phys Chem 231:1543

Subramania S, Choia SW, Lee JY, Kim JH (2007). Polymer 48:4691

Davoudizadeh S, Ghasemi M, Khezri K, Bahadorikhalili S (2017) J Therm Anal Calorim. https://doi.org/10.1007/s10973-017-6771-9

Sarsabili M, Rahmatolahzadeh R, Shobeiri SA, Hamadanian M, Farazin A, Khezri K (2017) Polym Adv Technol. https://doi.org/10.1002/pat.4131

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fazli, Y., Khezri, K. Well-defined PMMA/diatomite nanocomposites by in situ AGET ATRP: diatomite as an appropriate replacement for clay. J Polym Res 25, 9 (2018). https://doi.org/10.1007/s10965-017-1405-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1405-2