Abstract

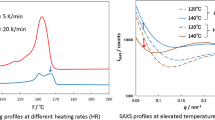

The influence of cryogenic mechanical milling on the structure and the thermal behavior of isotactic polypropylene was investigated by means of wide-angle X-ray scattering, differential scanning calorimetry and transmission electron microscopy. The results presented show that structural changes caused by mechanical milling at cryogenic temperatures are only partly reversible. The decrease in the degree of crystallinity as determined by differential scanning calorimetry with increasing milling time is attributed to a reversible transformation of the initial morphology into a “nanostructured” morphology, consisting of small “fragments” of the original isotactic polypropylene lamellae. During recrystallization from the molten state, there still exists an influence of the previous milling treatment, leading to significantly changed crystallization behavior. The reason for this behavior might be a decrease in the molecular weight or a change in the molecular weight distribution or the formation of long-chain branched polypropylene molecules induced by cryogenic mechanical milling.

Similar content being viewed by others

Notes

The crystallinity values χ cm and χ cc were determined by integration of the melting or crystallization peak areas and normalizing the resulting enthalpy values ΔH m or ΔH c to the specific enthalpy \( \Delta H^{{\text{0}}}_{{\text{m}}} \). The value \( \Delta H^{{\text{0}}}_{{\text{m}}} {\left( {{\text{iPP}}} \right)} = 209\;{\text{J}}/{\text{g}} \) was taken from the literature [21]

References

Khait K, Thorkelson JM (1999) Polym Plast Technol Eng 38:445

Furgiuele NM, Khait K, Torkelson JM (1998) J Am Chem Soc 216:156

Ganglani M, Torkelson JM, Carr SH, Khait K (2001) J Appl Polym Sci 80:671

Liu Y, Wang Q (2002) Polym J 34:132

Cavalieri F, Padella F, Bourbonneux S (2002) Polymer 43:1155

Smith AP, Spontak RJ, Koch CC, Smith SD, Ade H (2000) Macromol Mater Eng 274:1

Smith AP, Ade H, Balik CM, Koch CC, Smith SD, Spontak RJ (2000) Macromolecules 33:2595

Smith AP, Ade H, Koch CC, Smith SD, Spontak RJ (2000) Macromolecules 33:1163

Smith AP, Ade H, Smith SD, Koch CC, Spontak RJ (2001) Macromolecules 34:1536

Smith AP, Bai C, Ade H, Spontak RJ, Balik CM, Koch CC (1998) Macromol Rapid Commun 19:557

Folkes MJ, Hope PS (1995) Polymer blends and alloys. Chapman and Hall, New York, pp 46–73

Paul DR, Newman S (1978) Polymer blends, vol 2. Academic, New York, pp 35–60

Lebovitz AH, Khait K, Thorkelson JM (2002) Macromolecules 35:8672

Nesarikar AR, Carr SH, Khait K, Mirabella FM (1997) J Appl Polym Sci 63:1179

Chen Z, Wang Q (2001) Polym Int 50:966

Ratzsch M, Arnold M, Borsig E, Bucka H, Reichelt N (2002) Prog Polym Sci 27:1195

Frendel AC (2000) PhD thesis. TU Clausthal-Zellerfeld

Shaw WJD (1998) Mater Sci Forum 269–272:19

Petermann J, Gleiter H (1975) Philos Mag 31:929

Lu CH, Wang Q (2002) Chin J Struct Chem 21 1:7

Welsh WJ (1996) In: Mark JE (ed) Physical properties of polymers. American Institute of Physics, New York, pp 401–307

Zhu X, Li Y, Yan D, Zhu P, Lu Q (2001) Colloid Polym Sci 279:292

Kim YC, Ahn W, Kim CY (1997) Polym Eng Sci 37 6:1003

Padden FJ, Keith HD (1973) J Appl Phys 44:1217

Turner Jones A, Aizlewood JM, Beckett DR (1965) Macromol Chem 15:134

Cheng SZD, Janimak JJ, Zhang A (1990) Macromolecules 23:298

De Carvalho B, Bretas RES (1998) J Appl Polym Sci 68:1159

Philips PJ, Vatansever N (1987) Macromolecules 20:2138

Lovinger AJ (1983) J Polym Sci Polym Phys Ed 21:97

Norton DR, Keller A (1985) Polymer 26:704

Acknowledgements

This work was supported financially by the Deutsche Forschungsgemeinschaft (DFG Pe 220/25-1). The authors thank Henrike Bank for her help with some of the experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stranz, M., Köster, U. Irreversible structural changes in cryogenic mechanically milled isotactic polypropylene. Colloid Polym Sci 282, 381–386 (2004). https://doi.org/10.1007/s00396-003-0953-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-003-0953-7