Abstract

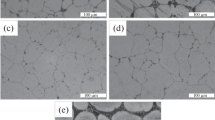

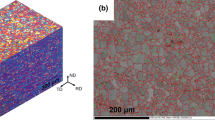

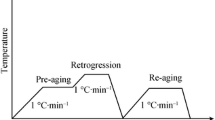

The influence of three kinds of alloy adding 0.3–1.8 wt% Zn on the mechanical properties and corrosion resistance of medium Mg content 4.0–4.5 wt% (5083 type) hot rolled alloy was investigated. The results showed that the addition of Zn content could further dissolve the second phases into the matrix. The hardness and tensile strength were reduced when annealing at 250 °C × 2 h. The mechanical behavior of the alloys showed a tendency that increases first and then decreases and the peak reached its maximum when 1.6 wt% Zn is added at both annealed and unannealed states. Through quantitative analysis, the improvement of mechanical properties mainly comes from dislocation strengthening and Al–Mg–Zn ternary strengthening phases. Meanwhile, with the increase of Zn content, the intergranular corrosion (IGC) of the alloy improved greatly after annealing at 250 °C × 2 h. The electrochemical corrosion potential (ECP) of the alloys increased first and then decreased.

Similar content being viewed by others

References

Z.L. Ni, F.X. Ye, Ultrasonic spot welding of aluminum alloys: a review. J. Manuf. Process 35, 580–594 (2018)

Z.H. Jia, H.L. Huang, X.L. Wang, Y. Xing, Q. Liu, Hafnium in aluminum alloys: a review. Acta Metallurgica Sinica (English Letters) 29(2), 105–119 (2016)

A.P. Hardwick, T. Outteridge, Vehicle lightweighting through the use of molybdenum-bearing advanced high-strength steels (AHSS). Int. J. Life Cycle Assess. 21(11), 1616–1623 (2015)

Y. Shi, L. Wang, P. Yu, The lightweight design and improvement of aluminum alloy automobile wheel. Appl. Mech. Mater. 63–64, 189–192 (2011)

S. Malopheyev, R. Kaibyshev, Strengthening mechanisms in a Zr-modified 5083 alloy deformed to high strains. Mater. Sci. Eng. A 620, 246–252 (2015)

R. Kaibyshev, F. Musin, D.R. Lesuer, T.G. Nieh, Superplastic behavior of an Al–Mg alloy at elevated temperatures. Mater. Sci. Eng. A 342(1–2), 169–177 (2003)

J.K. Paik, Mechanical properties of friction stir welded aluminum alloys 5083 and 5383. Int. J. Naval Arch. Ocean Eng. 1(1), 39–49 (2009)

K. Dudzik, M. Czechowski, Influence of joining method for mechanical properties of 5083, 5059 and 7020 aluminum alloys joints. Solid State Phenom. 220–221, 583–588 (2015)

Q. Ma, D. Zhang, L. Zhuang, J. Zhang, Intergranular corrosion resistance of Zn modified 5xxx series Al alloy during retrogression and re-aging treatment. Mater. Charact. 144, 264–273 (2018)

C. Meng, D. Zhang, H. Cui, L. Zhuang, J. Zhang, Mechanical properties, intergranular corrosion behavior and microstructure of Zn modified Al-Mg alloys. J. Alloys Compd. 617, 925–932 (2014)

M.C. Carroll, R.G. Buchheit, G.S. Daehn, M.J. Mills, Optimum trace copper levels for SCC resistance in a Zn-modified Al-5083 alloy. Mater. Sci. Forum 396–402, 1443–1448 (2002)

J.L. Ning, D.M. Jiang, Influence of Zr addition on the microstructure evolution and thermal stability of Al-Mg-Mn alloy processed by ECAP at elevated temperature. Mater. Sci. Eng. A 452–453, 552–557 (2007)

Z. Gao, H. Li, Y. Lai, Y. Ou, D. Li, Effects of minor Zr and Er on microstructure and mechanical properties of pure aluminum. Mater. Sci. Eng. A 580, 92–98 (2013)

M.C. Carroll, P.I. Gouma, M.J. Mills, G.S. Daehn, B.R. Dunbar, Effects of Zn additions on the grain boundary precipitation and corrosion of Al-5083. Scripta Mater. 42(4), 335–340 (2000)

D. Xiaoyuan, X. Changqing, W. Anru, W. Jiewen, Y. Li, Present research and developing trends of ultra high strength aluminum alloys contained scandium element. Mater. Rev. 20(5), 104–107 (2006)

X. Zhu, P. Blake, S. Ji, The formation mechanism of Al6(Fe, Mn) in die-cast Al-Mg alloys. Cryst. Eng. Commun. 20(27), 3839–3848 (2018)

X. Xu, H. Shao, J. Gao, K. Chen, X. Cheng, Effect of SiC film on tensile properties of nanostructured Ti produced by compressive deformation at liquid-nitrogen temperature. Mater. Sci. Eng. A 493(1–2), 195–201 (2008)

K.M. Youssef, R.O. Scattergood, K.L. Murty, C.C. Koch, Nanocrystalline Al-Mg alloy with ultrahigh strength and good ductility. Scripta Mater. 54(2), 251–256 (2006)

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, Y.T. Zhu, Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 52(15), 4589–4599 (2004)

S. Malopheyev, V. Kulitskiy, R. Kaibyshev, Deformation structures and strengthening mechanisms in an Al-Mg-Sc-Zr alloy. J. Alloys Compd. 698, 957–966 (2017)

S. Wang, X. Xu, C. Li, C. Cai, S. Ju, J. Huang, C. Wang, Q. Ding, Effect of pre-recovery on microstructure and properties of rolled Al-12.51Zn-2.85 Mg-2.83Cu-0.18Zr-0.06Sr aluminum alloy. Mater. Res. Expr. 6(10), 106549 (2019)

J.W. Zhao, B.H. Luo, K.J. He, Z.H. Bai, B. Li, W. Chen, Effects of minor Zn content on microstructure and corrosion properties of Al−Mg alloy. J. Central South Univ. 23(12), 3051–3059 (2016)

GB/T 7998-2005 test method for intergranular corrosion of aluminium alloy , Chinese National Standard. (2005)

Acknowledgement

This research is funded by Zhenjiang Key Research and Development Program (SGY20180110115).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, X., Jin, X., Liu, Z. et al. Influence of large amount Zn on mechanical properties and corrosion resistance of 5083 hot rolled aluminum alloy. Appl. Phys. A 126, 713 (2020). https://doi.org/10.1007/s00339-020-03908-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03908-5