Abstract

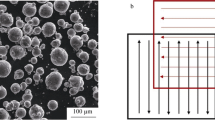

The selective laser melting (SLM) process parameters significantly affect the bonding of melting powders and the substrate or deposited layer, and the microstructure of end-use components. In this study, single track, double track and cubic sample SLM experiments were carried out to investigate the effect of process parameters on the surface morphology of SLM-fabricated AlSi10Mg alloy. The hierarchical microstructures discriminated by the Si phase are observed in SLM-processed AlSi10Mg samples. The formation mechanism of the hierarchical microstructures is elucidated. The formula proved that the solidification rate (R) increases gradually from the boundary to the center of the melt pool. Coarse zones are formed by the instantaneous existence of an extremely high ratio of thermal gradient (G) and solidification rate at the melt pool boundary, where solidification microstructure grows planar. With the heat propagating, a gradual change of the G/R ratio appears and the microstructure turns to columnar-dendritic growth, creating the fine zones.

Similar content being viewed by others

References

D. Herzog, V. Seyda, E. Wycisk, C. Emmelmann, Acta. Mater. 117, 371–392 (2016)

E. Louvis, P. Fox, C.J. Sutcliffe, J. Mater. Process. Technol. 211(2), 275–284 (2011)

J. Alloy, Compd. 734, 1414–1421 (2018)

X. Liu, C. Zhao, X. Zhou, Z. Shen, W. Liu, Mater. Des. 168, 107677 (2019)

A. Simchi, Mater. Sci. Eng. A 428(1–2), 148–158 (2006)

N.T. Aboulkhair, N.M. Everitt, I. Ashcroft, C. Tuck, Addit. Manuf. 1–4, 77–86 (2014)

L.Z. Wang, S. Wang, J.J. Wu, Opt. Laser. Technol. 96, 88–96 (2017)

N. Read, W. Wang, K. Essa, M.M. Attallah, Mater. Des. 65, 417–424 (2015). (1980-2015)

I. Rosenthal, M. Nahmany, A. Stern, N. Frage, Adv. Mater. Res. 1111, 62–66 (2015)

K. Kempen, L. Thijs, J. Van Humbeeck, J.P. Kruth, Phys. Procedia. 39, 439–446 (2012)

W. Li, S. Li, J. Liu, A. Zhang, Y. Zhou, Q. Wei, C. Yan, Y. Shi, Mater. Sci. Eng. A 663, 116–125 (2016)

J. Wu, X.Q. Wang, W. Wang, M.M. Attallah, M.H. Loretto, Acta. Mater. 117, 311–320 (2016)

C.A. Biffi, J. Fiocchi, A. Tuissi, J. Alloy. Compd. 755, 100–107 (2018)

M. Liu, N. Takata, A. Suzuki, M. Kobashi, Mater. Des. 157, 478–491 (2018)

C. Yan, L. Hao, A. Hussein, P. Young, J. Huang, W. Zhu, Mater. Sci. Eng. A 628, 238–246 (2015)

L. Zhou, A. Mehta, E. Schulz, B. McWilliams, K. Cho, Y. Sohn, Mater. Charact. 143, 5–17 (2018)

L. Thijs, K. Kempen, J.P. Kruth, J. Van Humbeeck, Acta. Mater. 61(5), 1809–1819 (2013)

P. Wei, Z. Wei, Z. Chen, J. Du, Y. He, J. Li, Y. Zhou, Appl. Surf. Sci. 408, 38–50 (2017)

C. Zhang, H. Zhu, Z. Hu, L. Zhang, X. Zeng, Mater. Sci. Eng. A 746, 416–423 (2019)

X. Zhou, X. Liu, D. Zhang, Z. Shen, W. Liu, J. Mater. Process. Technol. 222, 33–42 (2015)

N. Uzan, I. Rosenthal, A. Stern, Metall. Microstruct, Anal. 5(6), 512–519 (2016)

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath, A.M. Rubenchik, J. Mater. Process. Technol. 214(12), 2915–2925 (2014)

S.S. Dong, X.X. Zhang, F. Ma, J.Z. Jiang, W. Yang, Z.X. Lin, C.B. Chen, Mater. Res. Express 7, 025801 (2020)

W. Kurz, B. Giovanola, R. Trivedi, Acta metall 34(5), 823–883 (1985)

E. Brandl, U. Heckenberger, V. Holzinger, D. Buchbinder, Mater. Des. 34, 159–169 (2012)

W. Zhang, Welding Metallurgy: Fundamentals, 1st edn. (China Machine Press, Beijing, 2012), pp. 115–135

N. Takata, H. Kodaira, K. Sekizawa, A. Suzuki, M. Kobashi, Mater. Sci. Eng. A 704, 218–228 (2017)

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, W. Zhang, Prog. Mater. Sci. 92, 112–224 (2018)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China under Grant No. 51805313 and Industry-University-Research Collaboration Project between Shanghai University of Engineering Science and PMG 3D Technologies (Shanghai) Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, S., Zhang, X., Ma, F. et al. Research on deposited tracks and microstructures of AlSi10Mg alloy produced by selective laser melting. Appl. Phys. A 126, 643 (2020). https://doi.org/10.1007/s00339-020-03826-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03826-6