Abstract

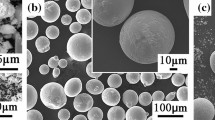

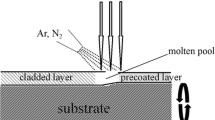

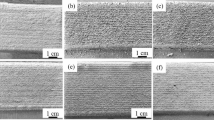

Ni-based composite coating added 10%TiC/1%CeO2, 20%TiC/1%CeO2, 20%TiC and 30%TiC/1%CeO2 (wt%) was prepared on the surface of H13 steel by laser cladding. The microstructure, hardness, friction and wear properties of the composite coatings was investigated by XRD, scanning electron microscopy (SEM) with energy-dispersive spectroscopy (EDS) and microhardness tester and friction abrasion tester. The result showed that the Ni-based composite coatings were mainly composed of the matrix γ-(Ni, Fe) solid solution and the reinforcement phases were TiC, Ni2Si, (Cr, Fe)7C3 and Cr23C6. TiC has less distribution at the bottom and more surface distribution in the coating as a hard phase and the microstructure was refined by the TiC/1%CeO2 addition. The hardness of the composite coating was improved by the TiC/1%CeO2 addition and the highest hardness was obtained when the TiC content was 30%. The composite coating has obviously more high wear resistance than the Ni60 coating, and the composite coating with 20% TiC/1%CeO2 addition acquired super wear resistance. The wear mechanism is mainly abrasive wear and some fatigue wear for the Ni60 coating, but turns to fatigue wear and brittle spalling for the composite coating, especially with high TiC content.

Similar content being viewed by others

References

P. Salazar, V. Rico, A.R. González-Elipe, Non-enzymatic hydrogen peroxide detection at NiO nanoporous thin film- electrodes prepared by physical vapor deposition at oblique angles. Electrochim. Acta 235, 534–542 (2017)

J.A. Stewart, D.E. Spearot, Phase-field simulations of microstructure evolution during physical vapor deposition of single-phase thin films. Comp. Mater. Sci. 131, 170–177 (2017)

S. Chaitoglou, E. Bertran, Effect of temperature on grap hene grown by chemical vapor deposition. J. Mater. Sci. 52(13), 8348–8356 (2017)

D. Macdonald, R. Fernández, F. Delloro et al., Cold spraying of armstrong process titanium powder for additive manufacturing. J. Therm. Spray. Technol. 26, 1–12 (2017)

F. Weng, H. Yu, C. Chen et al., Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J. Alloy. Compd. 692, 989–996 (2017)

C. Tan, H. Zhu, T. Kuang et al., Laser cladding Al-based amorphous- nanocrystalline composite coatings on AZ80 magnesium alloy under water cooling condition. J. Alloy. Compd. 690, 108–115 (2017)

M.Z. Mehrizi, M. Shamanian, A. Saidi et al., Evaluation of oxidation behavior of laser clad CoWSi–WSi2, coating on pure Ni substrate at different temperatures. Ceram. Int. 41(8), 9715–9721 (2015)

P. Farahmand, S. Liu, Z. Zhang et al., Laser cladding assisted by induction heating of Ni–WC composite enhanced by nano-WC and La2O3. Ceram. Int. 40(10), 15421–15438 (2014)

Y.F. Liu, Y.L. Zhou, Q. Zhang et al., Microstructure and dry sliding wear behavior of plasma transferred arc clad Ti5Si3, reinforced intermetallic composite coatings. J. Alloy. Compd. 591(591), 251–258 (2014)

Y. Lei, Sun R, Tang Y,et al, Microstructure and phase transformations in laser clad CrxSy/ Ni coating on H13 steel. Opt. Laser. Eng. 66, 181–186 (2015)

Y. Cai, Z. Luo, M. Feng et al., The effect of TiC/Al2O3 composite ceramic reinforcement on tribological behavior of laser cladding Ni60 alloys coatings. J. Surf. Coat. Technol. 291, 222–229 (2016)

Q. Ma, Y. Li, J. Wang, Effects of Ti addition on microstructure homogenization and wear resistance of wide-band laser clad Ni60/WC composite coatings. Int. J. Refract. Met. Hard Mater. 64, 225–233 (2016)

G. Cai, C. Li, Effects of Ce on inclusions, microstructure, mechanical Properties, and corrosion behavior of AISI 202 stainless steel. J. Mater. Eng. Perform. 24(10), 3989–4009 (2015)

Q. Li, Y. Lei, H. Fu, Laser cladding in-situ NbC particle reinforced Fe-based composite coatings with rare earth oxide addition. Surf. Coat. Technol. 239(2), 102–107 (2014)

N. Espallargas, J. Berget, J.M. Guilemany et al., Cr3 C2–NiCr and WC–Ni thermal spray coatings as alternatives to hard chromium for erosion–corrosion resistance. Surf. Coat. Technol. 202(8), 1405–1417 (2008)

S. Chaitoglou, E. Bertran, Effect of temperature on graphene grown by chemical vapor deposition. J. Mater. Sci. 52(13), 8348–8356 (2017)

A. Genç, E. Ayas, M.L. Öveçoğlu et al., Fabrication of in situ, Ni(W)–WC nano composites via mechanical alloying and spark plasma sintering. J. Alloy. Compd. 542(1), 97–104 (2012)

W.U. Chaofeng, M.A. Mingxing, W. Liu et al., Laser cladding in-situ carbide particle reinforced Fe-based composite coatings with rare earth oxide addition. J. Rare Earth 27(6), 997–1002 (2009)

F. Chang, D. Gu, D. Dai et al., Selective laser melting of in-situ Al4SiC4 + SiC hybrid reinforced Al matrix composites: influence of starting SiC particle size. Surf. Coat. Technol. 272, 15–24 (2015)

X.H. Wang, M. Zhang, X.M. Liu et al., Microstructure and wear properties of TiC/FeCrBSi surface composite coating prepared by laser cladding. Surf. Coat. Tech. 202(15), 3600–3606 (2008)

M.J. Chao, W.L. Wang, E.J. Liang et al., Microstructure and wear resistance of TaC reinforced Ni-based coating by laser cladding. Surf. Coat. Technol. 202(10), 1918–1922 (2008)

Q. Wu, W. Li, N. Zhong et al., Microstructure and wear behavior of laser cladding VC–Cr7C3, ceramic coating on steel substrate. Mater. Design. 49(16), 10–18 (2013)

J.S. Xu, X.C. Zhang, S.T. Tu, Microstructure and sliding wear resistance of laser cladded WC/Ni composite coatings with different contents of WC particle. J. Mater. Eng. Perform. 21(9), 1904–1911 (2012)

H. Kato, K. Komai, Tribofilm formation and mild wear by tribo-sintering of nanometer-sized oxide particles on rubbing steel surfaces. Wear. 262(1), 36–41 (2007)

X.-B. Liu, C. Zheng, Y.-F. Liu et al., A comparative study of laser cladding high temperature wear-resistant composite coating with the addition of self-lubricating WS2 and WS2/(N–P) encapsulation. J. Mater. Process. Technol. 213(1), 51–58 (2013)

X.-M. He, X.-B. Liu, M.-D. Wang, M.-S. Yang, S.-H. Shi, G.-Y. Fu, S.-F. Chen, Elevated temperature dry sliding wear behavior of nickel-based composite coating on austenitic stainless steel deposited by a novel central hollow laser cladding. Appl. Surf. Sci. 258(1), 535–541 (2011)

Acknowledgements

The authors gratefully acknowledge the financial support from the National Key R&D Program of China (No.2017YFB0305100), the Science and Technology Planning Project of Guandong Province, China (No.2017B090003005, 2015A040404023, 2014B090907005, 2017A090905027, 2017B090903005), the Guangzhou Science and Technology Plan Project (No. 201806040006) and the Fundamental Research Funds for the Central Universities (No. 11618406).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jinkang, H., Ying, L., Xueyang, Z. et al. Effects of TiC/CeO2 addition on microstructure and wear resistance of Ni-based composite coatings fabricated by laser cladding on H13 steel. Appl. Phys. A 125, 390 (2019). https://doi.org/10.1007/s00339-018-2328-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2328-4