Abstract

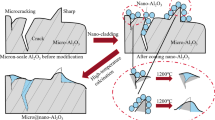

In this work, epoxy resin samples incorporated with nano-Al2O3 of various concentrations 0, 1, 3 and 5 wt% were prepared. Surface treatment of nano-Al2O3 was performed by the saline coupling agent of γ-aminopropyltriethoxysilane (KH550) to restrict the aggregation. The thermal gravimetric analysis (TGA) of the epoxy resin/Al2O3 nanocomposites was observed at different filler concentrations. TGA analysis indicated that incorporation of nano-Al2O3 increases the decomposition temperature as compared to pure epoxy resin. Moreover, 3 wt% filler concentration showed increased decomposition temperature because nanoparticles form close connections between molecules due to which thermal stability improved at higher temperatures. Atomic force microscopy was employed for the surface morphology of epoxy resin/Al2O3 nanocomposites which has indicated that surface roughness of epoxy resin/Al2O3 nanocomposites increased slightly with the filler concentration. The distribution of trap energy and trap density obtained by isothermal surface potential decay measurements revealed that 1 wt% filler concentration results in decrease in surface potential decay rate. In addition, significant increase in deep trap energy level and trap density was obvious at 1 wt% filler concentration. AC and DC breakdown strength of the samples was measured to evaluate the effect of filler concentrations on the electrical characteristics of epoxy resin. The results showed that breakdown strength of the epoxy resin/Al2O3 nanocomposites increases with the nano-Al2O3 concentration. Moreover, increase in trap energy results in an increase in the breakdown strength of the nanoparticles.

Similar content being viewed by others

References

Tanaka T (2005) Dielectric nanocomposites with insulating properties. IEEE Trans DielectrElectrInsul 12:914–928

Du BX, Xiao M (2014) Influence of surface charge on DC flashover characteristics of epoxy/BN nanocomposites. IEEE Trans DielectrElectrInsul 21:529–536

Farish O, Bawy IAl (1991) Effect of surface charge on impulse flashover of insulators in SF/sub 6. IEEE Trans DielectrElectrInsul 26:443–452

Yu ZQ, You SL, Yang ZG, Baier H (2011) Effect of surface functional modification of nano-alumina particles on thermal and mechanical properties of epoxy nanocomposites. Adv Comp Mater 20:487–502

Li Z, Okamoto K, Ohki Y, Tanaka T (2010) Effects of nano-filler addition on partial discharge resistance and dielectric breakdown strength of Micro-Al2O3/epoxy composite. IEEE Trans DielectrElectrInsul 17:653–661

Yamano Y, Iizuka M (2011) Improvement of electrical tree resistance of LDPE by mixed addition of nanoparticles and phthalocyanine. IEEE Trans DielectrElectrInsul 18:329–337

Singha S, Thomas MJ (2008) Dielectric properties of epoxy nanocomposites. IEEE Trans DielectrElectrInsul 15:12–23

Wang Q, Chen G (2014) Effect of pre-treatment of nanofillers on the dielectric properties of epoxy nanocomposites. IEEE Trans DielectrElectrInsul 21:1809–1816

Abdul Khalil HPS, Firoozian P, Bakare IO, Akil HM, Noor AM (2010) Exploring biomass based carbon black as filler in epoxy composites: flexural and thermal properties. Mater Des 31:3419–3425

Srivastava R, Srivastava D (2015) Preparation and thermo-mechanical characterization of novel epoxy resins using renewable resource materials. J Polym Environ 23:283–293

Kumar S, Samal SK, Mohanty S, Nayak SK (2017) Synthesis and characterization of nanoclay-reinforced trifunctional “bioresin-modified epoxy blends enhanced with mechanical and thermal properties. ChemSel 2:11445–11455

Afzal A, Siddiqi HM, Saeed S, Ahmad Z (2013) Exploring resin viscosity effects in solventless processing of nano-SiO2/epoxy polymer hybrids. RSC Adv 3:3885–3892

Khan MZ, Wang F, Li He Z, Shen ZH, Mehmood MA (2020) Influence of treated nano-alumina and gas-phase fluorination on the dielectric properties of epoxy resin/alumina nanocomposites. IEEE Trans DielectrElectrInsul 27:403–408

Khan MZ, Waleed A, Khan A, Hassan MAS, Paracha ZJ, Farooq U (2020) Significantly improved surface flashover characteristics of epoxy resin/Al2O3 nanocomposites in air, vacuum and SF6 by gas-phase fluorination. Electr Mater Sci 49:3400–3408

Wang F, Zhang T, Li J, Khan MZ, Huang Z, He Li, He Y (2019) DC breakdown and flashover characteristic of direct fluorinated epoxy/Al2O3nanocomposites. IEEE Trans DielectrElectrInsul 26:731–737

Asiri AM, Hussein MA, Zied BMA, Hermas AEA (2013) Effect of NiLaxFe2–xO4 nanoparticles on the thermal and coating properties of epoxy resin composites. Comp Part B Eng 51:11–18

Saba N, Paridah MT, Jawaid M, Alothman OY (2018) Thermal and flame retardancy behavior of oil palm based epoxy nanocomposites. J Polym Environ 26:1844–1853

Zhang H, Zhang H, Tang L, Liu G, Zhang D, Zhou L et al (2010) The effects of alumina nanofillers on mechanical properties of high-performance epoxy resin. J Nanosci and Nanotechnol 10:7526–7532

Fu CC (2014) A review on conduction mechanisms in dielectric films. Adv Mater SciEng. https://doi.org/10.1155/2014/578168

Wang W, Min D, Li S (2016) Understanding the conduction and breakdown properties of polyethylene nanodielectrics: effect of deep traps. IEEE Trans DielectrElectrInsul 23:564–572

Shen WW, Mu HB, Zhang GJ, Deng J-B, Tu DM (2013) Identification of electron and hole trap based on isothermal surface potential decay model. J ApplPhy 10(1063/1):4792491

Du BX, Li ZL (2015) Hydrophobicity, surface charge and DC flashover characteristics of direct-fluorinated RTV silicone rubber. IEEE Trans DielectrElectrInsul 22:934–940

Chen L, Zheng K, Tian X, Hu K, Wang R, Liu C et al (2010) Double glass transitions and interfacial immobilized layer in in-situ-synthesized poly(vinyl alcohol)/silica nanocomposites. Macromolecules 43:1076–1082

Tanaka T, Kozako M, Fuse N, Ohki Y (2005) Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans DielectrElectrInsul 12:669–681

Acknowledgements

The authors gratefully acknowledge supports from the National Key R&D Program of China (2017YFB0903801), Chongqing Municipality (cx2017041) and the project 111 of the Ministry of Education, China (B08036).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

khan, M.Z., Wang, F., Waleed, A. et al. Filler concentration effect on breakdown strength and trap level of epoxy resin–Al2O3 nanocomposites. Polym. Bull. 78, 5891–5903 (2021). https://doi.org/10.1007/s00289-020-03411-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03411-0