Abstract

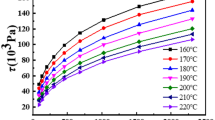

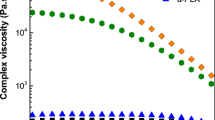

The present investigation dealt with the flow behavior and processability of polylactic acid/polystyrene (PLA/PS) polymer blends using a capillary rheometer. For this purpose, PLA/PS blends with different ratios of the concentrations were prepared using a single screw extruder. The shear viscosity, shear stress, shear rate, power-law index, viscous activation energy at a constant shear stress, and elongational stress were determined. PLA/PS blends exhibited a typical shear-thinning behavior over the entire range of shear rates tested, and the viscosity values of the blends would tend to decrease with increasing amount of PLA. In addition, the polymer blend of 70 % PLA and 30 % PS was found to be relatively less sensitive to the processing temperature, implying that the extrusion process was more desirable for fabrication of PLA/PS polymer blend than the injection process.

Similar content being viewed by others

References

Hamad K, Kaseem M, Yang HW, Ko YG (2015) Express Polym Lett 9:435

Lim LT, Auras R, Rubino M (2008) Prog Polym Sci 33:820

Avella M, Bogoeva-Gaceva G, Buzˇarovska A, Errico ME, Gentile G, Grozdanov A (2008) J Appl Polym Sci 108:3542

Dimzoski B, Bogoeva-Gaceva G, Avella M, Errico ME, Srebrenkoska V (2008) J Polym Eng 28:369

Roberto A, Rachele C, Gennaro G, Veronica A, Stefano F, Avella M, Mariacristina C, Errico ME (2015) Eur Polym J 66:533

Ishida S, Nagasaki R, Chino K, Dong T, Inoue Y (2009) J Appl Polym Sci 113:558

Wang N, Yu J, Ma X (2007) Polym Int 56:1440

Hamad K, Kaseem M, Deri F (2011) J Polym Res 18:1799

Hamad K, Kaseem M, Deri F (2012) Asia Pac J Chem Eng 7:S310

Mihai M, Huneault M, Favias B (2007) J Cell Plast 43:215

Schlemmer D, Sales M, Resck IS (2009) Carbohydr Polym 75:58

Hamad K, Kaseem M, Deri F, Ko YG (2016) Mater Lett 164:409

Biresaw G, Carriere CJ (2002) J Polym Sci B Polym Phys 40:2248

Sarazin P, Favis BD (2003) Biomacromolecules 4:1669

Vital A, Vayer M, Tillocher T, Dussart R, Boufnichel M, Sinturel C (2017) Appl Surf Sci 393:133

Tadmor Z, Gogos CG (2006) Principles of polymer processing. Wiley, New Jersey

Bagley EB (1957) J Appl Phys 28:624

Han CD (2007) Rheology and processing of polymeric materials (polymer rheology). Oxford University Press, New York

Kaseem M, Hamad K, Yang HW, Lee YH, Deri F, Ko YG (2015) Polym Sci Ser A 57:233

Hamad K, Kaseem M, Deri F (2012) J Biomater Nanobiotechnol 3:405

Wang N, Yu J, Chang P, Ma X (2008) Carbohydr Polym 71:109

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaseem, M., Ko, Y.G. Melt Flow Behavior and Processability of Polylactic Acid/Polystyrene (PLA/PS) Polymer Blends. J Polym Environ 25, 994–998 (2017). https://doi.org/10.1007/s10924-016-0873-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0873-5