Abstract

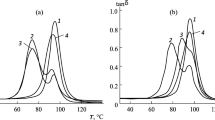

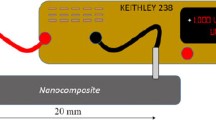

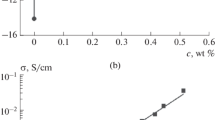

We report here a high dielectric percolative polymer nanocomposite, fabricated by a combination of triethylene-tetramine (TETA) modified multiwalled carbon nanotube (named as TETA-MWNT) within epoxy resin matrix. In this composite system, with various TETA-MWNT volume fractions, the dielectric constant (K) is well fitted by the scaling law of the percolation theory with the percolation threshold f c is 0.042 and the critical exponent p is 0.786. At 1,000 Hz of room temperature, the value of the dielectric constant is as high as 421 with the TETA-MWNT content of 4.14vol%, which is almost 60 times higher than that of epoxy resin. In contrast, a simple blend of pristine MWNT in epoxy composite shows evident lower dielectric constant and much higher loss with the same volume fraction.

Similar content being viewed by others

References

Zhang R, Baxendale M, Peijs T (2007) Universal resistivity–strain dependence of carbon nanotube/polymer composites. Phy Rev B 76:195433

Huang C, Zhang QM (2004) All—organic dielectric—percolative three-component composite materials with high electromechanical response. Appl Phys Lett 84:4391

Huang Y, Li N, Ma YF, Du F, Li FF, Chen YS et al (2007) The influence of single-walled carbon nanotube structure on the electromagnetic interference shielding efficiency of its epoxy composites. Carbon 45:1614

Dalmas F, Dendievel R, Chazeau L, Cavaille JY, Gauthier C (2006) Carbon nanotube-filled polymer of electrical conductivity in composites. Numerical simulation three-dimensional entangled fibrous networks. Acta Mater 54:2923

Yao SH, Dang ZM, Jiang MJ, Xu HP (2007) Influence of aspect ratio of carbon nanotube on percolation threshold in ferroelectric polymer nanocomposite. Appl Phys Lett 91:212901

Sandler J, Shaffer MSP, Prasse T, Bauhofer W, Schulte K, Windle AH (1999) Development of a dispersion process for carbon nanotubes in an epoxy matrix and the resulting electrical properties. Polymer 40:5967

Coleman JN, Curran S, Dalton AB, Davey AP, McCarthy B et al (1998) Percolation-dominated conductivity in a conjugated-polymer–carbon-nanotube composite. Phy Rev B 58:7492

Sandler JKW, Kirk JE, Kinloch IA, Shafferl MSP, Windle AH (2003) Ultra-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 44:5893

Kovacs JZ, Velagala BS, Schulte K, Bauhofer W (2007) Two percolation thresholds in carbon nanotube epoxy composites. Compos Sci Technol 67:922

Chang TE, Kisliuk A, Rhodes SM, Brittain WJ, Sokolov AP (2006) Conductivity and mechanical properties of well-dispersed single-wall carbon nanotube/polystyrene composite. Polymer 47:7740

Nogales A, Broza G, Roslaniec Z, Schulte K, Šics I et al (2004) Low percolation threshold in nanocomposites based on oxidized single wall carbon nanotubes and poly (butylene terephthalate). Maromolecules 37:7669

Gojny FH, Wichmann MH, Fiedler B, Kinloch LA et al (2006) Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer 47:2036

Wang JW, Shen QD, Yang CZ (2004) High dielectric constant composite of P(VDF-TrFE) with grafted copper phthalocyanine oligomer. Mcromolecules 37:2294

Park JG, Li S, Liang R, Zhang C, Wang B (2008) Structural changes and Raman analysis of single-walled carbon nanotube buckypaper after high current density induced burning. Carbon 46:1175

Gutierrez HR, Kim UJ, Kim JP, Eklund PC (2005) Thermal conversion of bundled carbon nanotubes into graphitic ribbons. Nano Lett 2195

Ahmad K, Pan W, Shi SL (2006) Electrical conductivity and dielectric properties of multiwalled carbon nanotube and alumina composites. Appl Phys Lett 89:133122

Krause S, Bohon K (2001) Electromechanical response of electrorheological fluids and poly(dimethylsiloxane) networks. Macromolecules 34:7179

Huang C, Zhang QM (2003) High-dielectric-constant all-polymer percolative composites. Appl Phys Lett 82:3503

Chen Q, Du PY, Jin L, Weng WJ, Han GR (2007) Percolative conductor/polymer composite films with significant dielectric properties. Appl Phys Lett 91:022912

Seanoe DA (1982) Electrical properties of polymers. Academic Press, New York

Bryning MB, Islam MF, Kikkawa JM, Yodh AG (2005) Very low conductivity threshold in bulk isotropic single-walled carbon nanotube-epoxy composites. Adv Mater 17:1186

Acknowledgments

This research was supported by the Hi-tech Research and Development Program China under Contract No2002AA334130, the Aeronautical Science Foundation of China under Contract No. 2006ZF52060, and the Natural Science Foundation of Jiangsu Province (No. BK2006194).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F., Wang, JW., Li, Sq. et al. Dielectric properties of epoxy composites with modified multiwalled carbon nanotubes. Polym. Bull. 63, 101–110 (2009). https://doi.org/10.1007/s00289-009-0064-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-009-0064-9