Abstract

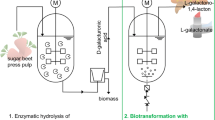

Caffeic acid (3,4-dihydroxycinnamic acid) serves as a building block for thermoplastics and a precursor for biologically active compounds and was recently produced from glucose by microbial fermentation. To produce caffeic acid from inedible cellulose, separate hydrolysis and fermentation (SHF) and simultaneous saccharification and fermentation (SSF) reactions were compared using kraft pulp as lignocellulosic feedstock. Here, a tyrosine-overproducing Escherichia coli strain was metabolically engineered to produce caffeic acid from glucose by introducing the genes encoding a 4-hydroxyphenyllactate 3-hydroxylase (hpaBC) from Pseudomonas aeruginosa and tyrosine ammonia lyase (fevV) from Streptomyces sp. WK-5344. Using the resulting recombinant strain, the maximum yield of caffeic acid in SSF (233 mg/L) far exceeded that by SHF (37.9 mg/L). In the SSF with low cellulase loads (≤2.5 filter paper unit/g glucan), caffeic acid production was markedly increased, while almost no glucose accumulation was detected, indicating that the E. coli cells experienced glucose limitation in this culture condition. Caffeic acid yield was also negatively correlated with the glucose concentration in the fermentation medium. In SHF, the formation of by-product acetate and the accumulation of potential fermentation inhibitors increased significantly with kraft pulp hydrolysate than filter paper hydrolysate. The combination of these inhibitors had synergistic effects on caffeic acid fermentation at low concentrations. With lower loads of cellulase in SSF, less potential fermentation inhibitors (furfural, 5-hydroxymethyfurfural, and 4-hydroxylbenzoic acid) accumulated in the medium. These observations suggest that glucose limitation in SSF is crucial for improving caffeic acid yield, owing to reduced by-product formation and fermentation inhibitor accumulation.

Similar content being viewed by others

References

Chauzar M, Tateyama S, Ishikura T, Matsumoto K, Kaneko D, Ebitani K, Kaneko T (2012) Hydrotalcites catalyze the acidolysis polymerization of phenolic acid to create highly heat-resistant bioplastics. Adv Funct Mater 22:3438–3444. doi:10.1002/adfm.201200427

Chung TW, Moon SK, Chang YC, Ko JH, Lee YC, Cho G, Kim SH, Kim JG, Kim CH (2004) Novel and therapeutic effect of caffeic acid and caffeic acid phenyl ester on hepatocarcinoma cells: complete regression of hepatoma growth and metastasis by dual mechanism. FASEB J 18:1670–1681. doi:10.1096/fj.04-2126com

Duchesne I, Hult E, Molin U, Daniel G, Iversen T, Lennholm H (2001) The influence of hemicellulose on fibril aggregation of kraft pulp fibres as revealed by FE-SEM and CP/MAS 13C-NMR. Cellulose 8:103–111. doi:10.1023/A:1016645809958

Furuya T, Kino K (2014) Catalytic activity of the two-component flavin-dependent monooxygenase from Pseudomonas aeruginosa toward cinnamic acid derivatives. Appl Microbiol Biotechnol 98:1145–1154. doi:10.1007/s00253-013-4958-y

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268. doi:10.1351/pac198759020257

Gomes CA, da Cruz TG, Andrade JL, Milhazes N, Borges F, Marques MPM (2003) Anticancer activity of phenolic acids of natural or synthetic origin: a structure-activity study. J Med Chem 46:5395–5401. doi:10.1021/jm030956v

Hamaguchi M, Cardoso M, Vakkilainen E (2012) Alternative technologies for biofuels production in kraft pulp mills: potential and prospects. Energ 5:288–2309. doi:10.3390/en5072288

Huang Q, Lin YH, Yan YJ (2013) Caffeic acid production enhancement by engineering a phenylalanine over-producing Escherichia coli strain. Biotechnol Bioeng 110:3188–3196. doi:10.1002/Bit.24988

Hult EL, Larsson PT, Iversen T (2000) A comparative CP/MAS 13C-NMR study of cellulose structure in spruce wood and kraft pulp. Cellulose 7:35–55. doi:10.1023/A:1009236932134

Jendresen CB, Stahlhut SG, Li MJ, Gaspar P, Siedler S, Forster J, Maury J, Borodina I, Nielsen AT (2015) Highly active and specific tyrosine ammonia-lyases from diverse origins enable enhanced production of aromatic compounds in bacteria and Saccharomyces cerevisiae. Appl Environ Microbiol 81:4458–4476. doi:10.1128/Aem.00405-15

Jones JA, Collins SM, Vernacchio VR, Lachance DM, Koffas MAG (2016) Optimization of naringenin and p-coumaric acid hydroxylation using the native E. coli hydroxylase complex, HpaBC. Biotechnol Prog 32:21–25. doi:10.1002/btpr.2185

Kaneko T, Thi TH, Shi DJ, Akashi M (2006) Environmentally degradable, high-performance thermoplastics from phenolic phytomonomers. Nat Mater 5:966–970. doi:10.1038/nmat1778

Kaneko D, Wang SQ, Matsumoto K, Kinugawa S, Yasaki K, Chi DH, Kaneko T (2011) Mussel-mimetic strong adhesive resin from bio-base polycoumarates. Polym J 43:855–858. doi:10.1038/pj.2011.77

Kawaguchi H, Uematsu K, Ogino C, Teramura H, Niimi-Nakamura S, Tsuge Y, Hasunuma T, Oinuma K, Takaya N, Kondo A (2014) Simultaneous saccharification and fermentation of kraft pulp by recombinant Escherichia coli for phenyllactic acid production. Biochem Eng J 88:188–194. doi:10.1016/j.bej.2014.04.014

Kawaguchi H, Teramura H, Uematsu K, Hara KY, Hasunuma T, Hirano K, Sazuka T, Kitano H, Tsuge Y, Kahar P, Niimi-Nakamura S, Oinuma KI, Takaya N, Kasuga S, Ogino C, Kondo A (2015) Phenyllactic acid production by simultaneous saccharification and fermentation of pretreated sorghum bagasse. Bioresour Technol 182:169–178. doi:10.1016/j.biortech.2015.01.097

Koopman F, Beekwilder J, Crimi B, van Houwelingen A, Hall RD, Bosch D, van Maris AJA, Pronk JT, Daran JM (2012) De novo production of the flavonoid naringenin in engineered Saccharomyces cerevisiae. Microb Cell Factories 11:155. doi:10.1186/1475-2859-11-155

Lin YH, Yan YJ (2012) Biosynthesis of caffeic acid in Escherichia coli using its endogenous hydroxylase complex. Microbial Cell Fact 11:670. doi:10.1186/1475-2859-11-42

Lin YH, Yan YJ (2014) Biotechnological production of plant-specific hydroxylated phenylpropanoids. Biotechnol Bioeng 111:1895–1899. doi:10.1002/bit.25237

Marinova M, Mateos-Espejel M, Jemaa N, Paris J (2009) Addressing the increased energy demand of a Kraft mill biorefinery: the hemicellulose extraction case. Chem Eng Res Des 87:1269–1275. doi:10.1016/j.chord.2009.04.017

Matsuoka Y, Shimizu K (2013) Catabolite regulation analysis of Escherichia coli for acetate overflow mechanism and co-consumption of multiple sugars based on systems biology approach using computer simulation. J Biotechnol 168:155–173. doi:10.1016/j.jbiotec.2013.06.023

Miller EN, Turner PC, Jarboe LR, Ingram LO (2010) Genetic changes that increase 5-hydroxymethyl furfural resistance in ethanol-producing Escherichia coli LY180. Biotechnol Lett 32:661–667. doi:10.1007/s10529-010-0209-9

Mooney CA, Mansfield SD, Touhy MG, Saddler JN (1998) The effect of initial pore volume and lignin content on the enzymatic hydrolysis of softwoods. Bioresour Technol 64:113–119. doi:10.1016/S0960-8524(97)00181-8

Nakagawa A, Minami H, Kim JS, Koyanagi T, Katayama T, Sato F, Kumagai H (2011) A bacterial platform for fermentative production of plant alkaloids. Nat Commun 2:326. doi:10.1038/Ncomms1327

Nguyen TN, Son S, Jordan MC, Levin DB, Ayele BT (2016) Lignin biosynthesis in wheat (Triticum aestivum L.): its response to waterlogging and association with hormonal levels. BMC Plant Biol 16:28. doi:10.1186/s12870-016-0717-4

Qi WW, Vannelli T, Breinig S, Ben-Bassat A, Gatenby AA, Haynie SL, Sariaslani FS (2007) Functional expression of prokaryotic and eukaryotic genes in Escherichia coli for conversion of glucose to p-hydroxystyrene. Metab Eng 9:268–276. doi:10.1016/j.ymben.2007.01.002

Rodrigues JL, Araújo RG, Prather KLJ, Kluskens LD, Rodrigues LR (2015) Heterologous production of caffeic acid from tyrosine in Escherichia coli. Enzym Microb Technol 71:36–44. doi:10.1016/j.enzmictec.2015.01.001

Sambrook J, Russell DW (2001) Molecular cloning: a laboratory manual, 3rd edn. Cold Spring Harbor Laboratory Press, New York

Satoh Y, Tajima K, Munekata M, Keasling JD, Lee TS (2012) Engineering of L-tyrosine oxidation in Escherichia coli and microbial production of hydroxytyrosol. Metab Eng 14:603–610. doi:10.1016/j.ymben.2012.08.002

Studier FW (2005) Protein production by auto-induction in high-density shaking cultures. Protein Expres Purif 41:207–234. doi:10.1016/j.pep.2005.01.016

Thomsen MH, Thygesen A, Thomsen AB (2009) Identification and characterization of fermentation inhibitors formed during hydrothermal treatment and following SSF of wheat straw. Appl Microbiol Biotechnol 83:447–455. doi:10.1007/s00253-009-1867-1

Tomoda H, Tabata N, Shinose M, Takahashi Y, Woodruff HB, Omura S (1999) Ferroverdins, inhibitors of cholesteryl ester transfer protein produced by Streptomyces sp WK-5344 - I. Production, isolation and biological properties. J Antibiot 52:1101–1107

Touaibia M, Jean-Francois J, Doiron J (2011) Caffeic acid, a versatile pharmacophore: an overview. Mini-Rev Med Chem 11:695–713. doi:10.2174/138955711796268750

Valgepea K, Adamberg K, Nahku R, Lahtvee PJ, Arike L, Vilu R (2010) Systems biology approach reveals that overflow metabolism of acetate in Escherichia coli is triggered by carbon catabolite repression of acetyl-CoA synthetase. BMC Syst Biol 4:166. doi:10.1186/1752-0509-4-166

Veit A, Polen T, Wendisch VF (2007) Global gene expression analysis of glucose overflow metabolism in Escherichia coli and reduction of aerobic acetate formation. Appl Microbiol Biotechnol 74:406–421. doi:10.1007/s00253-006-0680-3

Wang GF, Shi LP, Ren YD, Liu QF, Liu HF, Zhang RJ, Li Z, Zhu FH, He PL, Tang W, Tao PZ, Li C, Zhao WM, Zuo JP (2009) Anti-hepatitis B virus activity of chlorogenic acid, quinic acid and caffeic acid in vivo and in vitro. Antivir Res 83:186–190. doi:10.1016/j.antiviral.2009.05.002

Wang YC, Halls C, Zhang J, Matsuno M, Zhang YS, Yu O (2011) Stepwise increase of resveratrol biosynthesis in yeast Saccharomyces cerevisiae by metabolic engineering. Metab Eng 13:455–463. doi:10.1016/j.ymben.2011.04.005

Wang X, Yomano LP, Lee JY, York SW, Zheng HB, Mullinnix MT, Shanmugam KT, Ingram LO (2013) Engineering furfural tolerance in Escherichia coli improves the fermentation of lignocellulosic sugars into renewable chemicals. P Natl Acad Sci USA 110:4021–4026. doi:10.1073/pnas.1217958110

Wiselogel A, Tyson S, Johnson D (1996) Biomass feedstock resources and composition. In: Wyman CE (ed) Handbook on bioethanol: production and utilization. CRC Press, Washington, DC, pp 105–118

Xing Y, Peng HY, Zhang MX, Li X, Zeng WW, Yang XE (2012) Caffeic acid product from the highly copper-tolerant plant Elsholtzia splendens post-phytoremediation: its extraction, purification, and identification. J Zhejiang Univ Sci B 13:487–493. doi:10.1631/jzus.B1100298

Zaldivar J, Martinez A, Ingram LO (1999) Effect of selected aldehydes on the growth and fermentation of ethanologenic Escherichia coli. Biotechnol Bioeng 65:24–33. doi:10.1002/(Sici)1097-0290(19991005)65:1<24::Aid-Bit4>3.0.Co;2-2

Zhang HR, Stephanopoulos G (2013) Engineering E. coli for caffeic acid biosynthesis from renewable sugars. Appl Microbiol Biotechnol 97:3333–3341. doi:10.1007/s00253-012-4544-8

Acknowledgments

We gratefully acknowledge Nippon Paper Group (Japan) for providing kraft pulp samples and Kouji Uematsu and Teruaki Iwanari for providing technical assistance. This work was partly supported by JST CREST Grant Number JPMJCR13B3, Japan, and by Special Coordination Funds for Promoting Science and Technology, Creation of Innovation Centers for Advanced Inter-disciplinary Research Areas (Innovative Bioproduction, Kobe), from the Ministry of Education, Culture, Sports, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Human and animal rights and informed consent

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

.

ESM 1

(PDF 385 kb)

Rights and permissions

About this article

Cite this article

Kawaguchi, H., Katsuyama, Y., Danyao, D. et al. Caffeic acid production by simultaneous saccharification and fermentation of kraft pulp using recombinant Escherichia coli . Appl Microbiol Biotechnol 101, 5279–5290 (2017). https://doi.org/10.1007/s00253-017-8270-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8270-0