Abstract

Butanol has recently gained increasing interest due to escalating prices in petroleum fuels and concerns on the energy crisis. However, the butanol production cost with conventional acetone–butanol–ethanol fermentation by Clostridium spp. was higher than that of petrochemical processes due to the low butanol titer, yield, and productivity in bioprocesses. In particular, a low butanol titer usually leads to an extremely high recovery cost. Conventional biobutanol recovery by distillation is an energy-intensive process, which has largely restricted the economic production of biobutanol. This article thus reviews the latest studies on butanol recovery techniques including gas stripping, liquid–liquid extraction, adsorption, and membrane-based techniques, which can be used for in situ recovery of inhibitory products to enhance butanol production. The productivity of the fermentation system is improved efficiently using the in situ recovery technology; however, the recovered butanol titer remains low due to the limitations from each one of these recovery technologies, especially when the feed butanol concentration is lower than 1 % (w/v). Therefore, several innovative multi-stage hybrid processes have been proposed and are discussed in this review. These hybrid processes including two-stage gas stripping and multi-stage pervaporation have high butanol selectivity, considerably higher energy and production efficiency, and should outperform the conventional processes using single separation step or method. The development of these new integrated processes will give a momentum for the sustainable production of industrial biobutanol.

Similar content being viewed by others

References

Bankar SB, Survase SA, Singhal RS, Granstrom T (2012) Continuous two stage acetone–butanol–ethanol fermentation with integrated solvent removal using Clostridium acetobutylicum B5313. Bioresour Technol 106:110–116

Bankar SB, Survase SA, Ojamo H, Granström T (2013) The two stage immobilized column reactor with an integrated solvent recovery module for enhanced ABE production. Bioresour Technol 140:269–276

Chen CK, Blaschek HP (1999) Acetate enhances solvent production and prevents degeneration in Clostridium beijerinckii BA101. Appl Microbiol Biotechnol 52:170–173

Dai S, Ju YH, Barnes CE (1999) Solvent extraction of strontium nitrate by a crown ether using room-temperature ionic liquids. J Chem Soc Dalton Trans 8:1201–1202

Dhamole PB, Wang ZL, Liu YQ, Wang B, Feng H (2012) Extractive fermentation with non-ionic surfactants to enhance butanol production. Biomass and Bioenerg 40:112–119

Ennis BM, Marshall CT, Maddox IS, Paterson AHJ (1986) Continuous product recovery by in-situ gas stripping/condensation during solvent production from whey permeate using Clostridium acetobutylicum. Biotechnol Lett 8:725–730

Evanko WA, Eyal AM, Glassner DA, Miao F, Aristidou AA, Evans K, Gruber PR, Hawkins AC (2012a) Recovery of higher alcohols from dilute aqueous solutions. US 8304588:B2

Evanko WA, Eyal AM, Glassner DA, Miao F, Aristidou AA, Evans K, Gruber PR, Hawkins AC (2012b) Recovery of higher alcohols from dilute aqueous solutions. US 8101808:B2

Evanko WA, Eyal AM, Glassner DA, Miao F, Aristidou AA, Evans K, Gruber PR, Hawkins AC (2012c) Recovery of higher alcohols from dilute aqueous solutions. US 8283505:B2

Ezeji TC, Qureshi N, Blaschek HP (2003) Production of acetone, butanol and ethanol by Clostridium beijerinckii BA101 and in situ recovery by gas stripping. World J Microb Biot 19:595–603

Ezeji TC, Qureshi N, Blaschek HP (2004) Acetone butanol ethanol (ABE) production from concentrated substrate: reduction in substrate inhibition by fed-batch technique and product inhibition by gas stripping. Appl Microbiol Biotechnol 63:653–658

Ezeji TC, Qureshi N, Blaschek HP (2007) Production of acetone butanol (AB) from liquefied corn starch, a commercial substrate, using Clostridium beijerinckii coupled with product recovery by gas stripping. J Ind Microbiol Biot 34:771–777

Fadeev AG, Meagher MM, Kelley SS, Volkov VV (2000) Fouling of poly [−1-(trimethylsilyl)-1-propyne] membranes in pervaporative recovery of butanol from aqueous solutions and ABE fermentation broth. J Membr Sci 173:133–144

Fouad EA, Feng XS (2008) Use of pervaporation to separate butanol from dilute aqueous solutions: effects of operating conditions and concentration polarization. J Membr Sci 323:428–435

Friedl A, Qureshi N, Maddox IS (1991) Continuous acetone-butanol-ethanol (ABE) fermentation using immobilized cells of Clostridium acetobutylicum in a packed bed reactor and integration with product removal by pervaporation. Biotechnol Bioeng 38:518–527

Gapes JR, Nimcevic D, Friedl A (1996) Long-term continuous cultivation of Clostridium beijerinckii in a two-stage chemostat with on-line solvent removal. Appl Environ Microbiol 6:3210–3219

Garcia V, Pongrácz E, Muurinen E, Keiski RL (2009) Recovery of n-butanol from salt containing solutions by pervaporation. Desalination 241:201–211

García V, Pakkila J, Ojamo H, Muurinen E, Keiski RL (2011) Challenges in biobutanol production: how to improve the efficiency? Renew Sust Energ Rev 15:964–980

Grady MC, Jahic M, Patnaik R (2011) Method for producing butanol using two-phase extractive fermentation. US 20110294179:A1

Groot WJ, Luyben KCAM (1986) In situ product recovery by adsorption in the butanol/isopropanol batch fermentation. Appl Microbiol Biotechnol 25:29–31

Groot WJ, Luyben KCAM (1987) Continuous production of butanol from a glucose/xylose mixture with an immobilized cell system coupled to pervaporation. Biotechnol Lett 9:867–870

Groot WJ, Van der lans RGJM, Luyben KCAM (1992) Technologies for butanol recovery integrated with fermentations. Process Biochem 27:61–75

Ha SH, Mai NL, Koo YM (2010) Butanol recovery from aqueous solution into ionic liquids by liquid–liquid extraction. Process Biochem 45:1899–1903

Huddleston JG, Willauer HD, Swatloski RP, Visser AE, Rogers RD (1998) Room temperature ionic liquids as novel media for ‘clean’ liquid–liquid extraction. Chem Commun 44:1765–1766

Ishizak A, Michiwaki S, Crabbe E, Kobayashi G, Sonomoto K, Yoshino S (1999) Extractive acetone-butanol-ethanol fermentation using methylated crude palm oil as extractant in batch culture of Clostridium saccaroperbutylacetonicum N1-4 (ATCC 13564). J Biosci Bioeng 87:352–356

Jang YS, Lee J, Malaviya A, Seung DY, Cho JH, Lee SY (2012) Butanol production from renewable biomass: rediscovery of metabolic pathways and metabolic engineering. Biotechnol J 7:186–198

Jonquières A, Fane A (1997) Filled and unfilled composite GFT PDMS membranes for the recovery of butanols from dilute aqueous solutions: influence of alcohol polarity. J Membr Sci 125:245–255

Larrayoz MA, Puigjaner L (1987) Study of butanol extraction through pervaporation in acetobutylic fermentation. Biotechnol Bioeng 30:692–696

Li Q, Cai H, Hao B, Zhang CL, Yu ZN, Zhou SD, Liu CJ (2010a) Enhancing clostridial acetone–butanol–ethanol(ABE) production and improving fuel properties of ABE-enriched biodiesel by extractive fermentation with biodiesel. Appl Biochem Biotech 162:2381–2386

Li SY, Srivastava RJ, Parnas RS (2010b) Separation of 1-butanol by pervaporation using a novel tri-layer PDMS composite membrane. J Membr Sci 363:287–294

Li SY, Srivastava RJ, Parnas RS (2011) Study of in situ 1-butanol pervaporation from A-B-E fermentation using a PDMS composite membrane: validity of solution–diffusion model for pervaporative A-B-E fermentation. Biotechnol Progr 27:111–120

Lin X, Wu J, Jin X, Fan J, Li R, Wen Q, Qian W, Liu D, Chen X, Chen Y, Xie J, Bai J, Ying H (2012) Selective separation of biobutanol from acetone–butanol–ethanol fermentation broth by means of sorption methodology based on a novel macroporous resin. Biotechnol Prog 28:962–972

Liu XL, Li YS, Zhu GQ, Liu J, Yang WS (2011) Capillary supported ultrathin homogeneous silicalite-poly(dimethylsiloxane) nanocomposite membrane for bio-butanol recovery. J Membr Sci 369:228–232

Liu XB, Gu QY, Yu XB, Luo W (2012) Enhancement of butanol tolerance and butanol yield in Clostridium acetobutylicum mutant NT642 obtained by nitrogen ion beam implantation. J Microbiol 50:1024–1028

Lu CC, Zhao JB, Yang ST, Wei D (2012) Fed-batch fermentation for butanol production from cassava bagasse hydrolysate in a fibrous bed bioreactor with continuous gas stripping. Bioresour Technol 104:380–387

Lu CC, Dong J, Yang ST (2013) Butanol production from wood pulping hydrolysate in an integrated fermentation-gas stripping process. Bioresour Technol 143:467–475

Lütke-Eversloh T, Bahl H (2011) Metabolic engineering of Clostridium acetobutylicum: recent advances to improve butanol production. Curr Opin Biotech 22:634–647

Mariano AP, Qureshi N, Filho RM, Ezeji TC (2011) Bioproduction of butanol in bioreactors: new insights from simultaneous in situ butanol recovery to eliminate product toxicity. Biotechnol Bioeng 108:1757–1765

Matsumura M, Kataoka H, Sueki M, Araki K (1988) Energy saving effect of pervaporation using oleyl alcohol liquid membrane in butanol purification. Bioproc Eng 3:93–100

Matsumura M, Takehara S, Kataoka H (1992) Continuous butanol/isopropanol fermentation in down-flow column reactor coupled with pervaporation using supported liquid membrane. Biotechnol Bioeng 39:148–156

Milestone NB, Billy DM (1981) Concentration of alcohols by adsorption on silicalite. J Chem Technol Biotechnol 31:732–736

Moo-Young M (2011) Comprehensive biotechnology volume 3: industrial biotechnology and commodity products. Elsevier, The Netherlands

Nielsen D, Prather KJ (2009) In situ product recovery of n-butanol using polymeric resins. Biotechnol Bioeng 102:811–821

Oudshoorn A, van der Wielen LAM, Straathof AJJ (2009a) Adsorption equilibria of bio-based butanol solution using zeolite. Biochem Eng J 48:99–103

Oudshoorn A, van der Wielen LAM, Straathof AJJ (2009b) Assessment of options for selective 1-butanol recovery from aqueous solution. Ind Eng Chem Res 48:7325–7336

Papoutsakis ET (2008) Engineering solventogenic clostridia. Curr Opin Biotech 19:420–429

Qureshi N, Blaschek HP (2000) Butanol production using Clostridium beijerinckii BA101 hyper-butanol producing mutant strain and recovery by pervaporation. Appl Biochem Biotechnol 84:225–235

Qureshi N, Maddox IS (1991) Integration of continuous production and recovery of solvents from whey permeate: use of immobilized cells of Clostridium acetobutylicum in a fluidized bed reactor coupled with gas stripping. Bioproc Eng 6:63–69

Qureshi N, Maddox IS (1995) Continuous production of acetone–butanol–ethanol using immobilized cells of Clostridium acetobutylicum and integration with product removal by liquid–liquid extraction. J Ferment Bioeng 80:185–189

Qureshi N, Maddox IS (2005) Reduction in butanol inhibition by perstraction: utilization of concentrated lactose/whey permeate by Clostridium acetobutylicum to enhance butanol fermentation economics. Food Bioprod Process 83(C1):43–52

Qureshi N, Maddox IS, Friedl A (1992) Application of continuous substrate feeding to the ABE fermentation: relief of product inhibition using extraction, perstraction, stripping and pervaporation. Biotechnol Progr 8:382–390

Qureshi N, Meagher MM, Hutkins RW (1999) Recovery of butanol from model solutions and fermentation broth using a silicalite/silicone membrane. J Membrane Sci 158:115–125

Qureshi N, Meagher MM, Huang JC, Hutkins RW (2001) Acetone butanol ethanol (ABE) recovery by pervaporation using silicalite–silicone composite membrane from fed-batch reactor of Clostridium acetobutylicum. J Membr Sci 187:93–102

Qureshi N, Dien B, Saha BC, Ezeji TC, Blaschek HP, Cotta MA (2003) Separation of butanol from fermentation broth by pervaporation: mass flux and energy balance. AIChE Annual Meeting Nov 16–21; San Francisco, USA, 162B

Qureshi N, Hughes S, Maddox IS, Cotta MA (2005) Energy-efficient recovery of butanol from model solutions and fermentation broth by adsorption. Bioproc Biosyst Eng 27:215–222

Roffler SR, Blanch HW, Wilke CR (1987a) In-situ recovery of butanol during fermentation. Part 1: batch extractive fermentation. Bioproc Eng 2:1–12

Roffler SR, Blanch HW, Wilke CR (1987b) Extractive fermentation of acetone and butanol: process design and economic evaluation. Biotechnol Prog 3:131–140

Saravanan V, Waijers DA, Ziari M, Noordermeer MA (2010) Recovery of 1-butanol from aqueous solutions using zeolite ZSM-5 with a high Si/Al ratio; suitability of a column process for industrial applications. Biochem Eng J 49:33–39

SchuÈgerl K (2000) Integrated processing of biotechnology products. Biotechnol Adv 18:581–599

Setlhaku M, Heitmann S, Górak A, Wichmann R (2013) Investigation of gas stripping and pervaporation for improved feasibility of two-stage butanol production process. Bioresour Technol 136:102–108

Srinivasan K, Palanivelu K, Gopalakrishnan AN (2007) Recovery of 1-butanol from a model pharmaceutical aqueous waste by pervaporation. Chem Eng Sci 62:2905–2914

Thang VH, Kanka K, Kobayashi G (2010) Production of acetone-butanol-ethanol (ABE) in direct fermentation of cassava by Clostridium saccharoperbutylacetonicum N1-4. Appl Biochem Biotech 161:157–170

Thongsukmak A, Sirkar KK (2007) Pervaporation membranes highly selective for solvents present in fermentation broths. J Membr Sci 302:45–58

Tran HTM, Cheirsilp B, Hodgson B, Umsakul K (2010) Potential use of Bacillus subtilis in a co-culture with Clostridium butylicum for acetone–butanol–ethanol production from cassava starch. Biochem Eng J 48:260–267

Van Hecke W, Vandezande P, Claes S, Vangeel S, Beckers H, Diels L, De Wever H (2012) Integrated bioprocess for long-term continuous cultivation of Clostridium acetobutylicum coupled to pervaporation with PDMS composite membranes. Bioresour Technol 111:368–377

Vane LM (2008) Separation technologies for the recovery and dehydration of alcohols from fermentation broths. Biofuels Bioprod Bioref 2:553–588

Vrana DL, Meagher MM, Hutkins RW, Duffield B (1993) Pervaporation of model acetone–butanol–ethanol fermentation product solutions using polytetrafluoroethylene membranes. Sep Sci Technol 28:13–14

Xue C, Zhao JB, Lu CC, Yang ST, Bai FW, Tang IC (2012) High-titer n-butanol production by Clostridium acetobutylicum JB200 in fed-batch fermentation with intermittent gas stripping. Biotechnol Bioeng 109:2746–2756

Xue C, Zhao XQ, Liu CG, Chen LJ, Bai FW (2013a) Prospective and development of butanol as an advanced biofuel. Biotechnol Adv 31:1575–1587

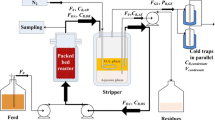

Xue C, Zhao JB, Liu FF, Lu CC, Yang ST, Bai FW (2013b) Two-stage in situ gas stripping for enhanced butanol fermentation and energy-saving product recovery. Bioresour Technol 135:396–402

Xue C, Du GQ, Sun JX, Chen LJ, Gao SS, Yu ML, Yang ST, Bai FW (2014) Characterization of gas stripping and its integration with acetone–butanol–ethanol fermentation for high-efficient butanol production and recovery. Biochem Eng J 83:55–61

Yang ST, Lu CC (2013) Extraction-fermentation hybrid (extractive fermentation). In: Ramaswamy S, Ramarao BV, Huang H (eds) Separation and purification technologies in biorefineries, vol Chapter 15. John Wiley & Sons, Ltd, Chichester, UK, pp 409–437

Yang X, Tsao GT (1995) Enhanced acetone–butanol fermentation using repeated fed-batch operation coupled with cell recycle by membrane and simultaneous removal of inhibitory products by adsorption. Biotechnol Bioeng 47:444–450

Yang X, Tsai GJ, Tsao GT (1994) Enhancement of in situ adsorption on the acetone–butanol fermentation by Clostridium acetobutylicum. Sep Technol 4:81–92

Zhao JB, Lu CC, Chen CC, Yang ST (2013) Biological production of butanol and higher alcohols. In: Yang ST, El-Enshasy HA, Thongchul N (eds) Bioprocessing technologies in biorefinery for sustainable production of fuels, chemicals, and polymers. John Wiley & Sons, Inc, Hoboken, NJ, USA, pp 235–261

Zheng YN, Li LZ, Xian M, Ma YJ, Yang JM, Xu X, He DZ (2009) Problems with the microbial production of butanol. J Ind Microbiol Biot 36:1127–1138

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NSFC) with grant numbers of 21306020 and 21376044, the Specialized Research Fund for the Doctoral Program of Higher Education of China (20130041120027), the Scientific Research Fund of Liaoning Provincial Education Department (L2013022), China Postdoctoral Science Foundation (2013M530904), the Open Research Fund from Biofuels Key Laboratory of Chinese Academy of Sciences in Qingdao Institute of Bioenergy and Bioprocess Technology (CASKLB201303), and the Scientific Research Foundation for the Returned Overseas Chinese Scholars of State Education Ministry.

Author information

Authors and Affiliations

Corresponding authors

Additional information

The authors Chuang Xue and Jing-Bo Zhao made equal contributions.

Rights and permissions

About this article

Cite this article

Xue, C., Zhao, JB., Chen, LJ. et al. Integrated butanol recovery for an advanced biofuel: current state and prospects. Appl Microbiol Biotechnol 98, 3463–3474 (2014). https://doi.org/10.1007/s00253-014-5561-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-5561-6