Abstract

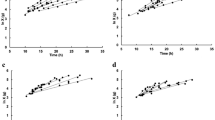

Conversion of lactose into ethyl acetate by Kluyveromyces marxianus allows economic reuse of whey-borne sugar. The high volatility of ethyl acetate enables its process-integrated recovery by stripping. This stripping is governed by both the aeration rate and the partition coefficient, K EA,L/G. Cultivation at elevated temperatures should decrease the K EA,L/G value and thus favor stripping. K. marxianus DSM 5422 as a potent producer of ethyl acetate was cultivated aerobically in whey-borne media for studying temperature-dependent growth and ester formation. Shake flask cultivation proved thermal tolerance of this yeast growing from 7 to 47 °C with a maximum rate of 0.75 h−1 at 40 °C. The biomass yield was 0.41 g/g at moderate temperatures while low and high temperatures caused distinct drops. The observed μ-T and Y X/S-T dependencies were described by mathematical models. Further cultivations were done in an 1-L stirred reactor for exploring the effect of temperature on ester synthesis. Cultivation at 32 °C caused significant ester formation (Y EA/S = 0.197 g/g) while cultivation at 42 °C suppressed ester synthesis (Y EA/S = 0.002 g/g). The high temperature affected metal dissolution from the bioreactor delivering iron for yeast growth and preventing ester synthesis. Cultivation at 32 °C with a switch to 42 °C at the onset of ester synthesis allowed quick and efficient ester production (Y EA/S = 0.289 g/g). The high temperature lowered the K EA,L/G value from 78 to 44 L/L which heightened the gas-phase ester concentration (favoring ester recovery) without increasing the liquid-phase concentration (avoiding product inhibition).

Similar content being viewed by others

References

Abdel-Banat BMA, Hoshida H, Ano A, Nonklang S, Akada R (2010) High-temperature fermentation: how can processes for ethanol production at high temperatures become superior to the traditional process using mesophilic yeast? Appl Microbiol Biotechnol 85:861–867

Antoce O-A, Antoce V, Takahashi K (1997) Calorimetric study of yeast growth and its inhibition by added ethanol at various pHs and temperatures. Netsu Sokutei 24(4):206–213

Arrhenius S (1908) Immunochemie. Ergeb Physiol 7:480–551

Aziz S, Memon HR, Shah FA, Rajoka MI, Soomro SA (2009) Production of ethanol by indigenous wild and mutant strain of thermotolerant Kluyveromyces marxianus under optimized fermentation conditions. Pak J Anal Environ Chem 10(1+2):25–33

Banat IM, Marchant R (1995) Characterization and potential industrial applications of five novel, thermotolerant, fermentative, yeast strains. World J Microbiol Biotechnol 11:304–306

Banat IM, Nigam P, Singh D, Marchant R, McHale AP (1998) Review: ethanol production at elevated temperatures and alcohol concentrations: Part I—yeasts in general. World J Microbiol Biotechnol 14:809–821

Beal C, Louvet P, Corrieu G (1989) Influence of controlled pH and temperature on the growth and acidification of pure cultures of Streptococcus thermophilus 404 and Lactobacillus bulgaricus 398. Appl Microbiol Biotechnol 32:148–154

Brady D, Nigam P, Marchant R, McHale AP (1997) Ethanol production at 45 °C by alginate-immobilized Kluyveromyces marxianus IMB3 during growth on lactose-containing media. Bioprocess Eng 16:101–104

Cardona CA, Sánchez OJ (2007) Fuel ethanol production: process design trends and integration opportunities. Biores Technol 98:2415–2457

Christensen AD, Kádár Z, Oleskowicz-Popiel P, Thomsen MH (2011) Production of bioethanol from organic whey using Kluyveromyces marxianus. J Ind Microbiol Biotechnol 38:283–289

Dragone G, Mussatto SI, Almeida e Silva JB, Teixeira JA (2011) Optimal fermentation conditions for maximizing the ethanol production by Kluyveromyces fragilis from cheese whey powder. Biomass Bioenergy 35:1977–1982

Duboc P, von Stockar U (1998) Systematic errors in data evaluation due to ethanol stripping and water vaporization. Biotechnol Bioeng 58:428–439

Esener AA, Roels JA, Kossen NWF (1981) The influence of temperature on the maximum specific growth rate of Klebsiella pneumoniae. Biotechnol Bioeng 23:1401–1405

Etschmann MMW, Sell D, Schrader J (2003) Screening of yeasts for the production of the aroma compound 2-phenylethanol in a molasses-based medium. Biotechnol Lett 25:531–536

Fatichenti F, Bernardi E (1987) Kluyveromyces fragilis SS-437: an associatively profiled thermotolerant yeast. Antonie van Leeuwenhoek 53:119–124

Garcia D, Ramos AJ, Sanchis V, Marín S (2009) Predicting mycotoxins in foods: a review. Food Microbiol 26:757–769

Ghaly AE, Kamal M, Avery A (2003) Influence of temperature rise on kinetic parameters during batch propagation of Kluyveromyces fragilis in cheese whey under ambient conditions. World J Microbiol Biotechnol 19:741–749

Guimarães PMR, Teixeira JA, Domingues L (2010) Fermentation of lactose to bio-ethanol by yeasts as part of integrated solutions for the valorisation of cheese whey. Biotechnol Adv 28:375–384

Grba S, Stehlik-Tomas V, Stanzer D, Vahčić N, Škrlin A (2002) Selection of yeast strain Kluyveromyces marxianus for alcohol and biomass production on whey. Chem Biochem Eng Q 16(1):13–16

Guo X, Zhou J, Xiao D (2010) Improved ethanol production by mixed immobilized cells of Kluyveromyces marxianus and Saccharomyces cerevisiae from cheese whey powder solution fermentation. Appl Biochem Biotechnol 160:532–538

Hinshelwood CN (1946) Influence of temperature on the growth of bacteria. In: The chemical kinetics of the bacterial cell. Clarendon, Oxford, pp 254–257

Hortsch R, Löser C, Bley T (2008) A two-stage CSTR cascade for studying the effect of inhibitory and toxic substances in bioprocesses. Eng Life Sci 8:650–657

Hughes DB, Tudroszen NJ, Moye CJ (1984) The effect of temperature on the kinetics of ethanol production by a thermotolerant strain of Kluyveromyces marxianus. Biotechnol Lett 6:1–6

Johnson FH, Lewin I (1946) The growth rate of E. coli in relation to temperature, quinine and coenzyme. J Cell Comp Physiol 28:47–75

Kallel-Mhiri H, Engasser J-M, Miclo A (1993) Continuous ethyl acetate production by Kluyveromyces fragilis on whey permeate. Appl Microbiol Biotechnol 40:201–205

Kallel-Mhiri H, Miclo A (1993) Mechanism of ethyl acetate synthesis by Kluyveromyces fragilis. FEMS Microbiol Lett 111:207–212

Kourkoutas Y, Dimitropoulou S, Kanellaki M, Marchant R, Nigam P, Banat IM, Koutinas AA (2002) High-temperature alcoholic fermentation of whey using Kluyveromyces marxianus IMB3 yeast immobilized on delignified cellulosic material. Biores Technol 82:177–181

Longhi LGS, Luvizetto DJ, Ferreira LS, Rech R, Ayub MAZ, Secchi AR (2004) A growth kinetic model of Kluyveromyces marxianus cultures on cheese whey as substrate. J Ind Microbiol Biotechnol 31:35–40

Löser C, Schröder A, Deponte S, Bley T (2005) Balancing the ethanol formation in continuous bioreactors with ethanol stripping. Eng Life Sci 5:325–332

Löser C, Urit T, Nehl F, Bley T (2011) Screening of Kluyveromyces strains for the production of ethyl acetate: design and evaluation of a cultivation system. Eng Life Sci 11:369–381

Löser C, Urit T, Förster S, Stukert A, Bley T (2012) Formation of ethyl acetate by Kluyveromyces marxianus on whey during aerobic batch and chemostat cultivation at iron limitation. Appl Microbiol Biotechnol 96:685–696

Löser C, Urit T, Stukert A, Bley T (2013) Formation of ethyl acetate from whey by Kluyveromyces marxianus on a pilot scale. J Biotechnol 163:17–23

Mussatto SI, Dragone G, Guimarães PMR, Silva JPA, Carneiro LM, Roberto IC, Vicente A, Domingues L, Teixeira JA (2010) Technological trends, global market, and challenges of bio-ethanol production. Biotechnol Adv 28:817–830

Panesar PS, Kennedy JF, Knill CJ, Kosseva M (2010) Production of L(+) lactic acid using Lactobacillus casei from whey. Braz Arch Biol Technol 53:219–226

Pinheiro R, Belo I, Mota M (2002) Oxidative stress response of Kluyveromyces marxianus to hydrogen peroxide, paraquat and pressure. Appl Microbiol Biotechnol 58:842–847

Pinheiro R, Belo I, Mota M (2003) Growth and β-galactosidase activity in cultures of Kluyveromyces marxianus under increased air pressure. Lett Appl Microbiol 37:438–442

Pohl P (2007) What do metals tell us about wine? Trends Anal Chem 26:941–949

Ratkowsky DA, Olley J, McMeekin TA, Ball A (1982) Relationship between temperature and growth rate of bacterial cultures. J Bacteriol 149:1–5

Ratkowsky DA, Lowry RK, McMeekin TA, Stokes AN, Chandler RE (1983) Model for bacterial culture growth rate throughout the entire biokinetic temperature range. J Bacteriol 154:1222–1226

Rosso L, Lobry JR, Flandrois JP (1993) An unexpected correlation between cardinal temperatures of microbial growth highlighted by a new model. J Theor Biol 162:447–463

Rosso L, Lobry JR, Bajard S, Flandrois JP (1995) Convenient model to describe the combined effects of temperature and pH on microbial growth. Appl Environ Microbiol 61:610–616

Sá-Correia I, van Uden N (1982) Effects of ethanol on thermal death and the maximum temperature for growth of the yeast Kluyveromyces fragilis. Biotechnol Lett 4:805–808

Sá-Correia I, van Uden N (1983) Temperature profiles of ethanol tolerance: effect of ethanol on the minimum and the maximum temperature for growth of the yeast S. cerevisiae and K. fragilis. Biotechnol Bioeng 25:1665–1667

Saerens SMG, Delvaux F, Verstrepen KJ, Van Dijck P, Thevelein JM, Delvaux FR (2008) Parameters affecting ethyl ester production by Saccharomyces cerevisiae during fermentation. Appl Environ Microbiol 74:454–461

Sampaio JP, Spencer-Martins I (1989) Adaptive growth at high temperatures of the lactose-fermenting yeast Kluyveromyces marxianus var. marxianus. J Basic Microbiol 29:61–64

Schoolfield RM, Sharpe PJH, Magnuson CE (1981) Non-linear regression of biological temperature-dependent rate models based on absolute reaction-rate theory. J Theor Biol 88:719–731

Sharpe PJH, DeMichele DW (1977) Reaction kinetics of poikilotherm development. J Theor Biol 64:649–670

Silveira WB, Passos FJV, Mantovani HC, Passos FML (2005) Ethanol production from cheese whey permeate by Kluyveromyces marxianus UFV-3: a flux analysis of oxido-reductive metabolism as a function of lactose concentration and oxygen levels. Enzyme Microb Technol 36:930–936

Szczodr J, Szewczuk D, Rogalski J, Fiedurek J (1997) Selection of yeast strain and fermentation conditions for high-yield ethanol production from lactose and concentrated whey. Acta Biotechnol 17:51–61

Urit T, Löser C, Wunderlich M, Bley T (2011) Formation of ethyl acetate by Kluyveromyces marxianus on whey: studies of the ester stripping. Bioprocess Biosyst Eng 34:547–559

Urit T, Löser C, Stukert A, Bley T (2012) Formation of ethyl acetate by Kluyveromyces marxianus on whey during aerobic batch cultivation at specific trace-element limitation. Appl Microbiol Biotechnol 96:1313–1323

Urit T, Manthey R, Bley T, Löser C (2013) Formation of ethyl acetate by Kluyveromyces marxianus on whey: influence of aeration and inhibition of yeast growth by ethyl acetate. Eng Life Sci 13:247–260

Vivier D, Ratomahenina R, Moulin G, Galzy P (1993) Study of physicochemical factors limiting the growth of Kluyveromyces marxianus. J Ind Microbiol 11:157–161

Ward C, Nolan AM, O’Hanlon K, McAree T, Barron N, McHale L, McHale AP (1995) Production of ethanol at 45 °C on starch-containing media by mixed cultures of the thermotolerant, ethanol-producing yeast Kluyveromyces marxianus IMB3 and the thermophilic filamentous fungus Talaromyces emersonii CBS 814.70. Appl Microbiol Biotechnol 43:408–411

Willetts A (1989) Ester formation from ethanol by Candida pseudotropicalis. Antonie van Leeuwenhoek 56:175–180

Wolter H, Lietz P, Beubler A (1966) Influence of temperature and yeast strain on the formation of amyl alcohol, isobutanol and ethyl acetate in fermenting malt wort. Folia Microbiol 11:210–214

Zourari A, Accolas JP, Desmazeaud MJ (1992) Metabolism and biochemical characteristics of yogurt bacteria. A review. Lait 72:1–34

Zwietering MH, de Koos JT, Hasenack BE, de Wit JC, van’t Riet K (1991) Modeling of bacterial growth as a function of temperature. Appl Environ Microbiol 57:1094–1101

Zwietering MH, Wijtzes T, Rombouts FM, van’t Riet K (1993) A decision support system for prediction of microbial spoilage in foods. J Ind Microbiol 12:324–329

Zwietering MH, de Wit JC, Notermans S (1996) Application of predictive microbiology to estimate the number of Bacillus cereus in pasteurised milk at the time of consumption. Int J Food Microbiol 30:55–70

Acknowledgments

Thanet Urit would like to express his thank to the Rajabhat Nakhon Sawan University (Muang Nakhon Sawan, Thailand) for financial support. We are grateful to Mrs. E. Kneschke from our institute for general technical assistance, to Dipl.-Ing. M. Heller from the Sachsenmilch AG (Leppersdorf, Germany) for providing whey permeate, and to Dr. H.-J. Stärk from the Helmholtz-Zentrum für Umweltforschung GmbH – UFZ (Leipzig, Germany) for analyzing trace metals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Urit, T., Li, M., Bley, T. et al. Growth of Kluyveromyces marxianus and formation of ethyl acetate depending on temperature. Appl Microbiol Biotechnol 97, 10359–10371 (2013). https://doi.org/10.1007/s00253-013-5278-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-5278-y