Abstract

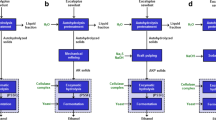

Lodgepole pine from forest thinnings is a potential feedstock for ethanol production. In this study, lodgepole pine was converted to ethanol with a yield of 276 L per metric ton of wood or 72% of theoretical yield. The lodgepole pine chips were directly subjected to sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL) pretreatment and then disk-milled; the recovered cellulose substrate was quais-simultaneously saccharified enzymatically and fermented to ethanol using commercial cellulases and Saccharomyces cerevisiae D5A. The liquor stream from the pretreatment containing hydrolyzed sugars mainly from hemicelluloses was fermented by the same yeast strain after detoxification using an XAD resin column. The SPORL pretreatment was conducted at 180°C for a period of 25 min with a liquor-to-wood ratio of 3:1 (v/w) in a laboratory digester. Three levels of sulfuric acid charge (0.0%, 1.4%, and 2.2% on an oven dried wood basis in w/w) and three levels of sodium bisulfite charge (0.0%, 4.0%, and 8.0% in w/w) were applied. Mechanical and thermal energy consumption for milling and pretreatment were determined. These data were used to determine the efficiency of sugar recoveries and net ethanol energy production values and to formulate a preliminary mass and energy balance.

Similar content being viewed by others

References

Aden A, Ruth M, Ibsen K, Jechura J, Neeves K, Sheehan J, Wallace B, Montague L, Slayton A, Lukas J (2002) Lignocellulosic biomass to ethanol process design and economic utilizing co-current dilute acid prehydrolysis and enzymatic hydrolysis for corn stover. National Renewable Energy Laboratory, Golden

Davis MW (1998) A rapid modified method for compositional carbohydrate analysis of lignocellulosics by high pH anion-exchange chromatography with pulsed amperometric detection (HPAEC/PAD). J Wood Chem Technol 18(2):235–352

De Bari I, Nanna F, Braccio G (2007) SO2-catalyzed steam fractionation of aspen chips for bioethanol production: optimization of the catalyst impregnation. Ind Eng Chem Res 46:7711–7720

Ewanick SM, Bura R, Saddler JN (2007) Acid-catalyzed steam pretreatment of lodgepole pine and subsequent enzymatic hydrolysis and fermentation to ethanol. Biotechnol Bioeng 98(1):737–746

Farrell AE, Plevin RJ, Turner BT, Jones AD, O’Hare M, Kammen DM (2006) Ethanol can contribute to energy and environmental goals. Science 311:506–508

Gable M, Zacchi G (2007) Pretreatment of lignocellulosic materials for efficient bioethanol production. Adv Biochem Engin/Biotechnol 108:41–65

Gierer J (1985) Chemistry of delignification-part 1: general concept and reactions during pulping. Wood Sci Technol 19(4):289–312

Hoyer K, Gable M, Zacchi G (2008) Production of fuel ethanol from softwood by simultaneous saccharification and fermentation at high dry matter content. J Chem Technol Biotechnol 84:570–577

Jeffries TW, Grigoriev IV, Grimwood J, Laplaza JM, Aerts A, Salamov A, Schmutz J, Lindquist E, Dehal P, Shapiro H et al (2007) Genome sequence of the lignocellulose-bioconverting and xylose-fermenting yeast Pichia stipitis. Nat Biotechnol 25(3):319–326

Jeffries TW, Jin Y-S (2004) Metabolic engineering for improved fermentation of xylose by yeasts. Appl Microbiol Biotechnol 63(5):495–509

Larsson S, Palmqvist E, Hahn-Hagerdal B, Tengborg C, Stenberg K, Zacchi G, Nilvebrant N-O (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb Technol 24:151–159

Lau MW, Dale BE (2009) Cellulosic ethanol production from AFEX-treated corn stover using Saccharomyces cerevisiae 414A(LNH-ST). PNAS 106(5):1368–1373

Lee J-W, Rodrigues RCLB, Jeffries TW (2009) Simultaneous saccharification and ethanol fermentation of corn cob pretreated with oxalic acid using response surface methodology. Bioresour Technol 100:6307–6311

Liu ZL, Slininger PJ, Gorsich SW (2005) Enhanced biotransformation of furfural and hydroxymethylfurfural by newly developed ethanologenic yeast strains. Appl Biochem Biotechnol 121–124:451–460

Monavari S, Gable M, Zacchi G (2009) Impact of impregnation time and chip size on sugar yield in pretreatment of softwood for ethanol production. Bioresour Technol 100:6312–6316

Munoz C, Mendonza R, Baeza J, Berlin A, Saddler J, Freer J (2007) Bioethanol production from bio-organosolv pulps of Pinus radiata and Acacia dealbata. J Chem Technol Biotechnol 82:767–774

Pan X, Xie D, Yu RW, Saddler JN (2008) The bioconversion of mountain pine beetle-killed lodgepople pine to fuel ethanol using the organosolv process. Biotechnol Bioeng 101(1):39–48

Pan XJ, Gilkes N, Kadla J, Pye K, Saka S, Gregg D, Ehara K, Xie D, Lam D, Saddler J (2006) Bioconversion of hybrid poplar to ethanol and co-products using an organosolv fractionation process: optimization of process yields. Biotechnol Bioeng 94(5):851–861

Perlack RD, Wright LL, Turhollow A, Graham RL, Stokes B, Erbach DC (2005) Biomass as feedstock for a bioenergy and bioproducts industry: The technical feasibility of a billion-ton annual supply. Oak Ridge National Laboratory, US Dept. of Energy, Oak Ridge

Sassner P, Martensson CG, Galbe M, Zacchi G (2008) Steam pretreatment of H2SO4-impregnated Salix for the production of bioethanol. Bioresour Technol 99(1):137–145

Sedlak M, Ho NWY (2004) Production of ethanol from cellulosic biomass hydrolysate using genetically engineered Saccharomyces yeast capable of cofermenting glucose and xylose. Appl Biochem Biotech 113–116:403–416

Shuai L, Yang Q, Zhu JY, Lu F, Weimer P, Ralph J, Pan XJ (2010) Comparative study of SPORL and dilute acid pretreatments of softwood spruce for cellulose ethanol production. Bioresour Technol doi:10.1016/j.biortech.2009.12.044

Soderstrom J, Galbe M, Zacchi G (2004) Effects of washing on yield in one- and two-step steam pretreatment of softwood for production of ethanol. Biotechnol Prog 20:744–749

van Vleet JH, Jeffries TW (2009) Yeast metabolic engineering for hemicellulosic ethanol production. Curr Opin Biotechnol 20(3):300–306

Wang GS, Pan XJ, Zhu JY, Gleisner R (2009) Sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL) for Robust Enzymatic Saccharification of Hardwoods. Biotech Prog 25(4):1086–1093

Weil JR, Dien B, Bothast R, Hendrickson R, Mosier NS, Ladisch MR (2002) Removal of fermentation inhibitors formed during pretreatment of biomass by polymeric adsorbents. Ind Eng Chem Res 41(24):6132–6138

Wingren A, Galbe M, Zacchi G (2003) Techno-economic evaluation of producing ethanol from softwood: comparison of SSF and SHF and identification of bottlenecks. Biotechnol Prog 19(4):1109–1117

Wyman CE, Dale BE, Elander RT, Holtzapple M, Ladisch MR, Lee YY (2005) Coordinated development of leading biomass pretreatment technologies. Bioresour Technol 96(18):1959–1966

Wyman CE, Dale BE, Elander RT, Holtzapple M, Ladisch MR, Lee YY, Mitchinson C, Saddler JN (2009) Comparative sugar recovery and fermentation data following pretreatment of poplar wood by leading technologies. Biotechnol Prog 25:333–339

Zhang X, Qin W, Paice MG, Saddler JN (2009) High consistency enzymatic hydrolysis of hardwood substrates. Bioresour Technol 100:5890–5897

Zhu JY, Pan XJ (2010) Woody biomass pretreatment for cellulosic ethanol production: technology and energy consumption evaluation. Bioresour Technol. doi:10.1016/j.biortech.2009.11.007

Zhu JY, Pan XJ, Wang GS, Gleisner R (2009a) Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour Technol 100(8):2411–2418

Zhu JY, Wang GS, Pan XJ, Gleisner R (2009b) Specific surface to evaluate the efficiencies of milling and pretreatment of wood for enzymatic saccharification. Chem Eng Sci 64(3):474–485

Zhu W, Zhu JY, Gleisner R, Pan XJ (2010) On energy consumption for size-reduction and yield from subsequent enzymatic sacchrification of pretreated lodgepole pine. Bioresour Technol. doi:10.1016/j.biortech.2009.10.076

Acknowledgments

We acknowledge Andy Youngblood and Tim Scott (both US Forest Service) for harvesting trees for the study. We especially appreciate Fred Matt and Diane Dietrich (both of the Forest Products Laboratory) for carrying out many careful analyses of carbohydrate of solids substrates and ethanol in SSF samples, respectively. The US Forest Service through the Program of Woody Biomass, Bioenergy, and Bioproducts (2008, 2009), the Chinese Scholarship Council, and the Ministry of Science and Technology of China provided financial support to W. Zhu and S. Tian for their visiting appointments at FPL.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was conducted on official US government time by Zhu (J.Y.), Glesiner, OBryan, and Dien, while Zhu (W.) and Tian were visiting scientists at the USDA Forest Service, Forest Products Laboratory. The work is in the public domain in the USA.

Rights and permissions

About this article

Cite this article

Zhu, J.Y., Zhu, W., OBryan, P. et al. Ethanol production from SPORL-pretreated lodgepole pine: preliminary evaluation of mass balance and process energy efficiency. Appl Microbiol Biotechnol 86, 1355–1365 (2010). https://doi.org/10.1007/s00253-009-2408-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-2408-7