Abstract

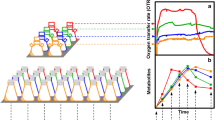

Oxygen supply is a key parameter in aerobic fermentation processes like the industrial production of amino acids. Although the oxygen transfer rate (OTR; or the volumetric oxygen transfer coefficient kLa) is routinely analyzed by engineers during stirred tank fermentations, it is often not taken into account by biologists conducting screening experiments in shake flasks. To show the importance of knowing how to avoid oxygen transfer limitations during primary screenings, Corynebacterium glutamicum ATCC 13032 (wild-type strain) and DSM 12866 (lysine-producing strain) were cultivated in shake flasks with different culture liquid volumes and under different shaking conditions. With the Respiration Activity Monitoring System, the OTR was determined quasi-continuously. Optical density as well as concentrations of lysine and byproducts (lactate, acetate, succinate) were determined off-line and correlated with the OTR signal. From the results, design criteria for improved screening in shaken bioreactors that help to avoid selection of suboptimal strains during early process development steps can be derived. Finally, the suitability of DSM 12866 as a strain for industrial processes with a high space–time yield is discussed.

Similar content being viewed by others

References

Almaas E, Kovács B, Vicsek T, Oltvai ZN, Barabási AL (2004) Global organization of metabolic fluxes in the bacterium Escherichia coli. Nature 427:839–843

Anderlei T, Büchs J (2001) Device for sterile online measurement of the oxygen transfer rate in shaking flasks. Biochem Eng J 7:157–162

Anderlei T, Zang W, Papaspyrou M, Büchs J (2004) Online respiration activity measurement (OTR, CTR, RQ) in shake flasks. Biochem Eng J 17:187–194

Büchs J (2001) Introduction to advantages and problems of shaken cultures. Biochem Eng J 7:91–98

Dominguez H, Nezondet C, Lindley ND, Cocaign M (1993) Modified carbon flux during oxygen limited growth of Corynebacterium glutamicum and the consequences for amino acid overproduction. Biotechnol Lett 15:449–454

Eggeling L, Oberle S, Sahm H (1998) Improved L-Lysine yield with Corynebacterium glutamicum: use of dapA resulting in increased flux combined with growth limitation. Appl Microbiol Biotechnol 49:24–30

Fischer E, Sauer U (2003) A novel metabolic cycle catalyzes glucose oxidation and anaplerosis in hungry Escherichia coli. J Biol Chem 278:46446–46451

Freyer SA, König M, Künkel A (2004) Validating shaking flasks as representative screening systems. Biochem Eng J 17:169–173

Gaden EL (1959) Fermentation process kinetics. J Biochem Microbiol Technol Eng 1:413–419

Hüser AT, Chassagnole C, Lindley ND, Merkamm M, Guyonvarch A, Elišáková V, Pátek M, Kalinowski J, Brune I, Pühler A, Tauch A (2005) Rational design of a Corynebacterium glutamicum pantothenate production strain and its characterization by metabolic flux analysis and genome-wide transcriptional profiling. Appl Environ Microbiol 71:3255–3268

Kensy F, Zimmermann HF, Knabben I, Anderlei T, Trauthwein H, Dingerdissen U, Büchs J (2005) Oxygen transfer phenomena in 48-well microtiter plates: determination by optical monitoring of sulfite oxidation and verification by real-time measurement during microbial growth. Biotechnol Bioeng 89:698–708

Kreutzer C, Hans S, Rieping M, Möckel B, Pfefferle W, Eggeling L, Sahm H, Pátek M (2001) L-lysine-producing corynebacteria and process for the preparation of lysine. US Patent #6200785

Kreutzer C, Möckel B, Pfefferle W, Eggeling L, Sahm H, Pátek M (2005) L-lysine-producing corynebacteria and process for the preparation of lysine. US Patent #6861246

Maier U, Büchs J (2001) Characterisation of the gas liquid mass transfer in shaking bioreactors. Biochem Eng J 7:99–106

Moser A (1988) Bioprocess technology. Springer, Berlin Heidelberg New York

Peters-Wendisch P, Stolz M, Etterich H, Kennerknecht N, Sahm H, Eggeling L (2005) Metabolic engineering of Corynebacterium glutamicum for L-serine production. Appl Environ Microbiol 71:7139–7144

Rainer BW (1990) Determination methods of the volumetric oxygen transfer coefficient kLa in bioreactors. Chem Biochem Eng 4:185–196

Van’t Riet K (1979) Review of measuring methods and results in nonviscous gas–liquid mass transfer in stirred vessels. Ind Eng Chem Process Des Dev 18:357–364

Varma A, Boesch BW, Palsson BO (1993) Stoichiometric interpretation of Escherichia coli glucose catabolism under various oxygenation rates. Appl Environ Microbiol 59:2465–2473

Wittmann C, Kim HM, John GT, Heinzle E (2003) Characterization and application of an optical sensor for quantification of dissolved O2 in shake-flasks. Biotechnol Lett 25:377–380

Wittmann C, de Graaf AA (2005) Metabolic flux analysis in Corynebacterium glutamicum. In: Eggeling L, Bott M (eds) Handbook of Corynebacterium glutamicum, CRC Press, Boca Raton, FL, pp 277–304

Acknowledgements

The authors wish to thank Markus Hornig for technical assistance, Stefan Hans for providing the bacterial strains, Uwe Bergmann for HPLC analytics, and Jörg Balla for lysine determinations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zimmermann, H.F., Anderlei, T., Büchs, J. et al. Oxygen limitation is a pitfall during screening for industrial strains. Appl Microbiol Biotechnol 72, 1157–1160 (2006). https://doi.org/10.1007/s00253-006-0414-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0414-6