Abstract

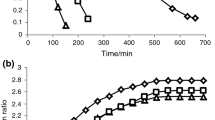

The purpose of this study is to compare convective and infrared heating as means of drying pomegranate arils. The drying process was conducted at 50, 60 and 70 °C. The minimal times required to reach 9 ± 0.2% moisture (mass/mass) starting from 78 ± 0.2% were 510 and 94 min respectively for convective and infrared drying. Calculation of aril effective diffusivity (Deff) was based on Fick’s second law of diffusion. At all temperatures, Deff values ranged from 2.56·10–10 to 4.75·10–10 m2/s, and from 0.87·10–9 to 2.64·10–9 m2/s respectively for convective and infrared drying. Effective moisture diffusivity (Deff) values were found to increase as temperature to increase. Pomegranate is one of the major sources of polyphenolic phytochemicals. Polyphenol stability might be affected by heat treatments that are required during drying. Based on the maximal total polyphenol content (205 ± 0.89 mg/100 g) of the dried product, the optimal temperature for infrared drying was 50 °C. This product also had an intense garnet-red color and a satisfactory rehydration capacity. Various models of drying kinetics were tested for conformity with the results obtained in this study. The model that best fit the drying data was the modified logistic model of Midilli et al., than other models.

Similar content being viewed by others

References

Adak N, Heybeli N, Ertekin C (2017) Infrared drying of strawberry. Food Chem 219:109–116

Afolabi TJ, Tunde-Akintunde TY, Adeyanju JA (2015) Mathematical modeling of drying kinetics of untreated and pretreated cocoyam slices. J Food Sci Technol 52:2731–2740

Aghbashlo M (2016) Exergetic simulation of a combined infrared-convective drying process. Heat Mass Transf 52:829–844

Alcaraz-Mármol F, Nuncio-Jáuregui N, García-Sánchez F, Martínez-Nicolás JJ, Hernández F (2017) Characterization of twenty pomegranate (Punica granatum L.) cultivars grown in Spain: aptitudes for fresh consumption and processing. Sci Hortic 219:152–160

AOAC (1990) Official Methods of Analysis, 15th edn. (Association of Official Analytical Chemists, Washington DC)

Aral S, Beşe AV (2016) Convective drying of hawthorn fruit (Crataegus spp.): effect of experimental parameters on drying kinetics, color, shrinkage, and rehydration capacity. Food Chem 210:577–584

Babu AK, Kumaresan G, Antony Aroul Raj V, Velraj R (2018) Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew Sust Energ Rev 90:536–556

Bchir B, Besbes S, Karoui R, Attia H, Paquot M, Blecker C (2012) Effect of air-drying conditions on physico-chemical properties of osmotically pre-treated pomegranate seeds. Food Bioprocess Technol 5:1840–1852

Behera G, Sutar PP (2018) A comprehensive review of mathematical modeling of paddy parboiling and drying: effects of modern techniques on process kinetics and rice quality. Trends Food Sci Technol 75:206–230

Beigi M (2017) Thin layer drying of wormwood (Artemisia absinthium L.) leaves: dehydration characteristics, rehydration capacity and energy consumption. Heat Mass Transf 53:2711–2718

Brandão RJ, Borel LDMS, Marques LG, Prado MM (2016) Heat and mass transfer, energy and product quality aspects in drying processes using infrared radiation. In: Delgado JMPQ, de Lima AGB (eds) Drying and energy technologies. Springer International Publishing, Cham, pp 111–130

Bruce DM (1985) Exposed layer barley drying, three models fitted to new data up to 150 °C. J Agric Engr Res 32:337–47

Calín-Sánchez Á, Figiel A, Hernández F, Melgarejo P, Lech K, Carbonell-Barrachina ÁA (2013) Chemical composition, antioxidant capacity, and sensory quality of pomegranate (Punica granatum L.) arils and rind as affected by drying method. Food Bioprocess Technol 6:1644–1654

Cano-Lamadrid M, Lech K, Michalska A, Wasilewska M, Figiel A, Wojdylo A, Carbonell-Barrachina AA (2017) Influence of osmotic dehydration pre-treatment and combined drying method on physico-chemical and sensory properties of pomegranate arils, cultivar Mollar de Elche. Food Chem 232:306–315

Cao X, Cai C, Wang Y, Zheng X (2018) The inactivation kinetics of polyphenol oxidase and peroxidase in bayberry juice during thermal and ultrasound treatments. Innovative Food Sci Emerg Technol 45:169–178

Castro AM, Mayorga EY, Moreno FL (2018) Mathematical modelling of convective drying of fruits: a review. J Food Eng 223:152–167

Chen Q, Bi J, Wu X, Yi J, Zhou L, Zhou Y (2015) Drying kinetics and quality attributes of jujube (Zizyphus jujuba miller) slices dried by hot-air and short- and medium-wave infrared radiation. LWT Food Sci Technol 64:759–766

Chen NN, Chen MQ, Fu BA, Song JJ (2017) Far-infrared irradiation drying behavior of typical biomass briquettes. Energy 121:726–738

Dak M, Sagar VR, Jha SK (2014) Shelf-life and kinetics of quality change of dried pomegranate arils in flexible packaging. Food Packaging and Shelf Life 2:1–6

Dash K, Gope S, Sethi A, Doloi M (2013) Study on thin layer drying characteristics star fruit slices. International Journal Agriculture and Food Science Technology 4:679–686

de Oliveira Carvalho J, Orlanda JFF (2017) Heat stability and effect of pH on enzyme activity of polyphenol oxidase in Buriti (Mauritia flexuosa Linnaeus f.) fruit extract. Food Chem 233:159–163

Demir VÃ, Gunhan T, Yagcioglu AK (2007) Mathematical modeling of convection drying of green table olives. Biosyst Engr 98:47–53

Diamanti AC, Igoumenidis PE, Mourtzinos I, Yannakopoulou K, Karathanos VT (2017) Green extraction of polyphenols from whole pomegranate fruit using cyclodextrins. Food Chem 214:61–66

Doymaz İ (2011a) Drying of pomegranate arils and selection of a suitable drying model. Food Biophysics 6:461–467

Doymaz İ (2011b) Prediction of drying characteristics of pomegranate arils. Food Anal Methods 5:841–848

Doymaz İ (2012) Drying of pomegranate seeds using infrared radiation. Food Sci Biotechnol 21:1269–1275

Ergün K, Çalışkan G, Dirim SN (2016) Determination of the drying and rehydration kinetics of freeze dried kiwi (Actinidia deliciosa) slices. Heat Mass Transf 52:2697–2705

Galaz P, Valdenegro M, Ramírez C, Nuñez H, Almonacid S, Simpson R (2017) Effect of drum drying temperature on drying kinetic and polyphenol contents in pomegranate peel. J Food Eng 208:19–27

Ghasemi A, Chayjan RA (2018) Optimization of pelleting and infrared-convection drying processes of food and agricultural waste using response surface methodology (RSM). Waste and Biomass Valorization 10(6):1711–1729

Glouannec P, Lecharpentier D, Noel H (2002) Experimental survey on the combination of radiating infrared and microwave sources for the drying of porous material. Appl Therm Eng 22:1689–1703

Hammouda I, Mihoubi D (2014) Comparative numerical study of kaolin clay with three drying methods: convective, convective–microwave and convective infrared modes. Energy Convers Manag 87:832–839

Hashim N, Daniel O, Rahaman E (2014) A preliminary study: kinetic model of drying process of pumpkins (Cucurbita Moschata) in a convective hot air dryer. Agriculture and Agricultural Science Procedia 2:345–352

Horuz E, Maskan M (2015) Hot air and microwave drying of pomegranate (Punica granatum L.) arils. J Food Sci Technol 52:285–293

Horuz E, Bozkurt H, Karataş H, Maskan M (2017) Effects of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chem 230:295–305

Łechtańska JM, Szadzińska J, Kowalski SJ (2015) Microwave- and infrared-assisted convective drying of green pepper: quality and energy considerations. Chem Eng Process Process Intensif 98:155–164

Midilli A, Kucuk H, Yapar Z (2002) A new model for single-layer drying. Dry Technol 20:1503–1513

Mphahlele RR, Fawole OA, Makunga NP, Opara UL (2016) Effect of drying on the bioactive compounds, antioxidant, antibacterial and antityrosinase activities of pomegranate peel. BMC Complement Altern Med 16:143

Nowicka P, Wojdyło A, Lech K, Figiel A (2015) Influence of Osmodehydration pretreatment and combined drying method on the bioactive potential of sour cherry fruits. Food Bioprocess Technol 8:824–836

Onwude DI, Hashim N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: a review. Compr Rev Food Sci Food Saf 15:599–618

Onwude DI, Hashim N, Abdan K, Janius R, Chen G (2018a) Modelling the mid-infrared drying of sweet potato: kinetics, mass and heat transfer parameters, and energy consumption. Heat Mass Transf 54:2917–2933

Onwude DI, Hashim N, Abdan K, Janius R, Chen G, Kumar C (2018b) Modelling of coupled heat and mass transfer for combined infrared and hot-air drying of sweet potato. J Food Eng 228:12–24

Overhults DG, White GM, Hamilton HE, Ross IJ (1973) Drying soybeans with heated air. Trans ASAE 16:112–113

Özdemir MB, Aktaş M, Şevik S, Khanlari A (2017) Modeling of a convective-infrared kiwifruit drying process. Int J Hydrog Energy 42:18005–18013

Page GE (1949) Factors influencing the maximum rates of air drying shelled corn in thin–layers. M.S.Thesis, Purdue University, West Lafayette, Indiana.

Parlak N (2014) Fluidized bed drying characteristics and modeling of ginger (zingiber officinale) slices. Heat Mass Transf 51:1085–1095

Ramos KK, Lessio BC, Mecê ALB, Efraim P (2017) Mathematical modeling of uvaia byproduct drying and evaluation of quality parameters. Food Sci Biotechnol 26:643–651

Sacilik K (2007) Effect of drying methods on thin-layer drying characteristics of hull-less seed pumpkin (Cucurbita pepo L.). J Food Eng 79:23–30

Toğrul H (2006) Suitable drying model for infrared drying of carrot. J Food Eng 77:610–619

Toğrul İT, Pehlivan D (2002) Mathematical modelling of solar drying of apricots in thin layers. J Food Eng 55:209–216

Venkitasamy C, Zhu C, Brandl MT, Niederholzer FJA, Zhang R, McHugh TH, Pan Z (2018) Feasibility of using sequential infrared and hot air for almond drying and inactivation of Enterococcus faecium NRRL B-2354. LWT 95:123–128

Viuda-Martos M, Fernández-López J, Pérez-Álvarez JA (2010) Pomegranate and its many functional components as related to human health: a review. Compr Rev Food Sci Food Saf 9:635–654

Wang C, Singh RP (1978) Use of variable equilibrium moisture content in modeling rice drying. Trans Am Soc Agric Eng 11:668–672

Yilmaz FM, Ksekkaya SY, Vardin H, Karaaslan M, (2017) The effects of drying conditions on moisture transfer and quality of pomegranate fruit leather (pestil). J Saudi Soc Agric Sci 16:33–40

Younis M, Abdelkarim D, Zein El-Abdein A (2018) Kinetics and mathematical modeling of infrared thin-layer drying of garlic slices. Saudi J Biol Sci 25:332–338

Zenoozian MS, Feng H, Razavi S, Shahidi F, Pourreza H (2008) Image analysis and dynamic modeling of thin-layer drying of osmotically dehydrated pumpkin. J Food Process Preserv 32:88–102

Zielinska M, Michalska A (2016) Microwave-assisted drying of blueberry (Vaccinium corymbosum L.) fruits: drying kinetics, polyphenols, anthocyanins, antioxidant capacity, colour and texture. Food Chem 212:671–680

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Briki, S., Zitouni, B., Bechaa, B. et al. Comparison of convective and infrared heating as means of drying pomegranate arils (Punica granatum L.). Heat Mass Transfer 55, 3189–3199 (2019). https://doi.org/10.1007/s00231-019-02644-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02644-8