Abstract

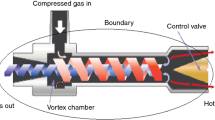

This research article demonstrates how using different turbulence models may affect the temperature detachment (the temperature diminution of cold air (∆Tc = Ti − Tc)) inside straight counter-flow Ranque-Hilsch Vortex Tube (RHVT). The code is utilized to find the optimized turbulence model for energy separation by comparison with the experimental data of the setup. To obtain the results with a minimum error, various turbulence models have been investigated in steady state and transient time-dependence modes. Results show that RNG k-ε turbulence model has the best correspondence with the obtained experimental data from the setup; therefore, by using a RNG k-ε turbulence model with respect to Finite Volume Method (FVM), all the computations have been carried out. Moreover, some geometric parameters are focused on the length of hot tube and number of nozzle intakes within divergent and convergent hot-tube. Numerical results present that there is an optimum angle for obtaining the highest refrigeration performance, and 2ο divergence is the optimal candidate under our numerical analysis conditions. Length of hot tube which exceeds a critical length has slight effect on the refrigeration capacity. The critical length is L = 166 mm in our study. Temperature reduction sensitivity can be reduced by increasing number of nozzles and maximum temperature reduction can be obtained.

Similar content being viewed by others

Abbreviations

- ANN:

-

Artificial neural network

- CFD:

-

Computational fluid dynamic

- FVM:

-

Finite volume method

- RANS:

-

Reynolds average navier stokes

- RNG:

-

Renormalized group

- RHVT:

-

Ranque-Hilsch vortex tube

- RH:

-

Ranque-Hilsch

- RHE:

-

Ranque-Hilsch effect

- LES:

-

Large eddy simulation

- VT:

-

Vortex tube

- ∆T c = ( T in − T C):

-

Temperature difference between inlet and cold outlet

- ΔT = ( T H − T C):

-

Temperature difference between hot and cold outlets

- C p :

-

Specific heat at constant absolute pressure (J.kg−1.K−1)

- C εi :

-

Coefficients (i = 1, 2) used in ε equation

- C μ :

-

Constants in Eq. 14

- C υ :

-

Constants in Eq. 13

- D:

-

Diameter of vortex tube (mm)

- \( \overset{\cdot }{m} \) :

-

Mass flow rate (kg.s−1)

- d n :

-

Diameter of inlet nozzle (mm)

- E:

-

Total energy (kJ)

- G k :

-

Generation of turbulence kinetic energy

- k:

-

Turbulence kinetic energy (m2.s−2)

- Ke :

-

Thermal conductivity (W.m−1.K−1)

- L:

-

Length (mm)

- N:

-

Number of inlet nozzle

- P:

-

Absolute pressure (pa)

- Q c :

-

Cooling rate

- Prt :

-

Turbulent Prandtl number

- R:

-

Specific constant of an ideal gas (J/kgmol-K)

- S :

-

Twice the strain rate tensor (s−1)

- T:

-

Temperature (K)

- ui :

-

Absolute fluid velocity component in i-direction (m/s)

- YM :

-

Contribution of the fluctuating dilatation

- Ma:

-

Mach number

- W:

-

Mechanical energy

- α k :

-

Inverse effective Prandtl numbers in Eq. 11

- α ε :

-

Inverse effective Prandtl numbers in Eq. 12

- δ ij :

-

Kronecker delta

- τ:

-

Shear stress (N.m−2)

- (τ ij)eff :

-

Deviatoric stress tensor (N.m−2)

- ε :

-

Turbulence dissipation rate (m−2.s−3)

- α :

-

Cold mass fraction

- μ:

-

Dynamic viscosity (kg.m−1.s−1)

- υ :

-

Kinematic viscosity (m2.s−1)

- \( \widehat{\upsilon} \) :

-

Ratio of effective viscosity to the dynamic viscosity

- γ:

-

Specific heat ratio

- ρ:

-

Density (kg.m−3)

- λ :

-

Pressure Loss Ratio

- η 0, β, η :

-

Coefficients in RNG k- ε model

- η is :

-

Isentropic efficiency

- c:

-

Cold gas

- eff:

-

Effective

- h:

-

Hot gas

- in:

-

Inlet gas

- is:

-

isentropic

- i, j, k:

-

Cartesian indicates

- n:

-

nozzle

- t:

-

turbulent

- st:

-

static

- a:

-

Atmospheric

References

Ranque G (1933) Experiences sur la d’etente giratoire avec productions simultan\ ees d’un echappement d’air chaud et d’un echappement d’air froid. J Phys Radium 4:112–114

Hilsch R (1946) Die expansion von Gasen im Zentrifugalfeld als Kälteprozess. Zeitschrift für Naturforschung A 1:208–214

Nellis G, Klein S (2002) The application of vortex tubes to refrigeration cycles

Rafiee SE, Sadeghiazad M (2017) Experimental and 3D CFD analysis on optimization of geometrical parameters of parallel vortex tube cyclone separator. Aerosp Sci Technol 63:110–122

Dincer K, Avci A, Baskaya S, Berber A (2010) Experimental investigation and exergy analysis of the performance of a counter flow Ranque–Hilsch vortex tube with regard to nozzle cross-section areas. Int J Refrig 33:954–962

Takahama H (1965) Energy Separation of Gas by Vortex Tube. Tran J Soc Mech Eng 68:1255–1263

Piralishvili SA, Fuzeeva A (2005) Hydraulic characteristics of Ranque-Hilsch energy separators. High Temp 43:900–907

Shannak BA (2004) Temperature separation and friction losses in vortex tube. Heat Mass Transf 40:779–785

Dincer K, Baskaya S, Uysal B (2008) Experimental investigation of the effects of length to diameter ratio and nozzle number on the performance of counter flow Ranque–Hilsch vortex tubes. Heat Mass Transf 44:367–373

Nimbalkar SU, Muller MR (2009) An experimental investigation of the optimum geometry for the cold end orifice of a vortex tube. Appl Therm Eng 29:509–514

Saidi M, Valipour M (2003) Experimental modeling of vortex tube refrigerator. Appl Therm Eng 23:1971–1980

Behera U, Paul P, Kasthurirengan S, Karunanithi R, Ram S, Dinesh K et al (2005) CFD analysis and experimental investigations towards optimizing the parameters of Ranque–Hilsch vortex tube. Int J Heat Mass Transf 48:1961–1973

Eiamsa-ard S, Wongcharee K, Promvonge P (2010) Experimental investigation on energy separation in a counter-flow Ranque–Hilsch vortex tube: Effect of cooling a hot tube. International Communications in Heat and Mass Transfer 37:156–162

Pinar AM, Uluer O, Kırmaci V (2009) Optimization of counter flow Ranque–Hilsch vortex tube performance using Taguchi method. Int J Refrig 32:1487–1494

Chang K, Li Q, Zhou G, Li Q (2011) Experimental investigation of vortex tube refrigerator with a divergent hot tube. Int J Refrig 34:322–327

Takahama H, Yokosawa H (1981) An experimental study of the vortex tube-Where the vortex chamber includes a divergent tube. Nagoya University Faculty Engineering Memoirs 33:195–208

Uluer O, Kırmacı V, Ataş Ş (2009) Using the artificial neural network model for modeling the performance of the counter flow vortex tube. Expert Syst Appl 36:12256–12263

Korkmaz ME, Gümüşel L, Markal B (2012) Using artificial neural network for predicting performance of the Ranque–Hilsch vortex tube. Int J Refrig 35:1690–1696

Valipour MS, Niazi N (2011) Experimental modeling of a curved Ranque–Hilsch vortex tube refrigerator. Int J Refrig 34:1109–1116

Yilmaz M, Kaya M, Karagoz S, Erdogan S (2009) A review on design criteria for vortex tubes. Heat Mass Transf 45:613–632

Kassner R, Knoernschild E (1948) Friction laws and energy transfer in circular flow. Part 1-The Law of Shear Stresses in Circular Flow. Part 2-Energy Transfer in Circular Flow and Possible Applications (Explanation of the Hilsch or Ranque Effect). Air Materiel Command Wright-Patterson AFB OH1948

Elser K, Hoch M (1951) Das Verhalten verschiedener Gase und die Trennung von Gasgemischen in einem Wirbelrohr. Zeitschrift für Naturforschung A 6:25–31

Deissler R, Perlmutter M (1960) Analysis of the flow and energy separation in a turbulent vortex. Int J Heat Mass Transf 1:173–191

Reynolds AJ (1961) Energy flows in a vortex tube. Zeitschrift für Angewandte Mathematik und Physik (ZAMP) 12:343–357

Erdélyi I (1962) Wirkung des Zentrifugalkraftfeldes auf den Wärmezustand der Gase, Erklärung der Ranque-Erscheinung. Forsch Ingenieurwes 28:181–186

Sibulkin M (1962) Unsteady, viscous, circular flow part 3. application to the Ranque-Hilsch vortex tube. J Fluid Mech 12:269–293

Gulyaev A (1965) Ranque effect at low temperatures. J Eng Phys Thermophys 9:242–244

Bruun H (1969) Experimental investigation of the energy separation in vortex tubes. J Mech Eng Sci 11:567–582

Linderstrøm-Lang C (1971) The three-dimensional distributions of tangential velocity and total-temperature in vortex tubes. J Fluid Mech 45:161–187

Yokosawa H (1981) Energy Separation in Yerfei Tubes with a Diwergent Chamber. Taper 8:1–72

Kurosaka M (1982) Acoustic streaming in swirling flow and the Ranque—Hilsch (vortex-tube) effect. J Fluid Mech 124:139–172

Stephan K, Lin S, Durst M, Huang F, Seher D (1983) An investigation of energy separation in a vortex tube. Int J Heat Mass Transf 26:341–348

Stephan K, Lin S, Durst M, Huang F, Seher D (1984) A similarity relation for energy separation in a vortex tube. Int J Heat Mass Transf 27:911–920

Eckert E (1986) Energy separation in fluid streams. International Communications in Heat and Mass Transfer 13:127–143

Balmer R (1988) Pressure driven Ranque Hilsch temperature separation in liquids. J Fluids Eng 110:161–164

Ahlborn B, Keller J, Staudt R, Treitz G, Rebhan E (1994) Limits of temperature separation in a vortex tube. J Phys D Appl Phys 27:480

Ahlborn B, Groves S (1997) Secondary flow in a vortex tube. Fluid Dynamics Research 21:73–86

Gutsol A (1997) The ranque effect. Physics-Uspekhi 40:639–658

Gutsol A, Bakken J (1998) A new vortex method of plasma insulation and explanation of the Ranque effect. J Phys D Appl Phys 31:704

Fröhlingsdorf W, Unger H (1999) Numerical investigations of the compressible flow and the energy separation in the Ranque–Hilsch vortex tube. Int J Heat Mass Transf 42:415–422

Mischner J, Bespalov V (2002) Zur Entropieproduktion im Ranque–Hilsch–Rohr. Forsch Ingenieurwes 67:1–10

Aljuwayhel N, Nellis G, Klein S (2005) Parametric and internal study of the vortex tube using a CFD model. Int J Refrig 28:442–450

Gao C, Bosschaart K, Zeegers J, De Waele A (2005) Experimental study on a simple Ranque–Hilsch vortex tube. Cryogenics 45:173–183

Piralishvili SA, Fuzeeva A (2006) Similarity of the energy-separation process in vortex Ranque tubes. J Eng Phys Thermophys 79:27–32

Skye H, Nellis G, Klein S (2006) Comparison of CFD analysis to empirical data in a commercial vortex tube. Int J Refrig 29:71–80

Ui-Hyun J, Lakshmana Gowda BHL (2006) Experimental and numerical studies in a vortex tube. J Mech Sci Technol 20(3):418–425

Aydın O, Baki M (2006) An experimental study on the design parameters of a counterflow vortex tube. Energy 31:2763–2772

Eiamsa-ard S, Promvonge P (2007) Numerical investigation of the thermal separation in a Ranque–Hilsch vortex tube. Int J Heat Mass Transf 50:821–832

Eiamsa-ard S, Promvonge P (2008) Review of Ranque–Hilsch effects in vortex tubes. Renew Sust Energ Rev 12:1822–1842

She Z-S, Jackson E, Orszag SA (1990) Intermittant Vortex Structures in Homogeneous Isotropic Turbulence. Nature 344:226

Xue Y, Arjomandi M (2008) The effect of vortex angle on the efficiency of the Ranque–Hilsch vortex tube. Exp Thermal Fluid Sci 33:54–57

Secchiaroli A, Ricci R, Montelpare S, D’Alessandro V (2009) Numerical simulation of turbulent flow in a Ranque–Hilsch vortex tube. Int J Heat Mass Transf 52:5496–5511

Zin K, Hansske A, Ziegler F (2010) Modeling and optimization of the vortex tube with computational fluid dynamic analysis. Energy Research Journal 1:193–196

Xue Y, Arjomandi M, Kelso R (2010) A critical review of temperature separation in a vortex tube. Exp Thermal Fluid Sci 34:1367–1374

Xue Y, Arjomandi M, Kelso R (2013) Experimental study of the thermal separation in a vortex tube. Exp Thermal Fluid Sci 46:175–182

Liu X, Liu Z (2014) Investigation of the energy separation effect and flow mechanism inside a vortex tube. Appl Therm Eng 67:494–506

Xue Y, Arjomandi M, Kelso R (2014) Energy analysis within a vortex tube. Exp Thermal Fluid Sci 52:139–145

Kobiela B (2014) Wärmeübertragung in einer Zyklonkühlkammer einer Gasturbinenschaufel: Verlag Dr. Hut

Thakare HR, Monde A, Parekh AD (2015) Experimental, computational and optimization studies of temperature separation and flow physics of vortex tube: A review. Renew Sust Energ Rev 52:1043–1071

Manimaran R (2016) Computational analysis of energy separation in a counter-flow vortex tube based on inlet shape and aspect ratio. Energy 107:17–28

Sharma TK, Rao GAP, Murthy KM (2017) Numerical Analysis of a Vortex Tube: A Review. Archives of Computational Methods in Engineering 24:251–280

Smith E-a, Pongjet P (2006) Numerical prediction of vortex flow and thermal separation in a subsonic vortex tube. Journal of Zhejiang University-SCIENCE A 7:1406–1415

Farouk T, Farouk B (2007) Large eddy simulations of the flow field and temperature separation in the Ranque–Hilsch vortex tube. Int J Heat Mass Transf 50:4724–4735

Farouk T, Farouk B, Gutsol A (2009) Simulation of gas species and temperature separation in the counter-flow Ranque–Hilsch vortex tube using the large eddy simulation technique. Int J Heat Mass Transf 52:3320–3333

Lai J, Yang C (1997) Numerical simulation of turbulence suppression: Comparisons of the performance of four k-ϵ turbulence models. Int J Heat Fluid Flow 18:575–584

Eiamsa-ard S, Promvonge P (2008) Numerical simulation of flow field and temperature separation in a vortex tube. International Communications in Heat and Mass Transfer 35:937–947

Baghdad M, Ouadha A, Imine O, Addad Y (2011) Numerical study of energy separation in a vortex tube with different RANS models. Int J Therm Sci 50:2377–2385

Dutta T, Sinhamahapatra K, Bandyopdhyay S (2010) Comparison of different turbulence models in predicting the temperature separation in a Ranque–Hilsch vortex tube. Int J Refrig 33:783–792

Kundu PK, Cohen IM, Dowling D (2008) Fluid Mechanics, 4th ed. Elsevier, Oxford

Fluent I (2006) FLUENT 6.3 user’s guide. Fluent documentation

Choudhury D (1993) Introduction to the renormalization group method and turbulence modeling: Fluent Incorporated

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bazgir, A., Khosravi-Nikou, M. & Heydari, A. Numerical CFD analysis and experimental investigation of the geometric performance parameter influences on the counter-flow Ranque-Hilsch vortex tube (C-RHVT) by using optimized turbulence model. Heat Mass Transfer 55, 2559–2591 (2019). https://doi.org/10.1007/s00231-019-02578-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02578-1