Abstract

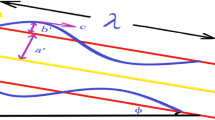

The main objective of this study is to capture the function of temperature separation inside a vortex tube (VT), firstly, via testing it at different inlet pressures (4, 5, 6, and 7 bar) and then examining the best performance of the VT through computational fluid dynamics (CFD) along with three various Reynolds-averaged Navier–Stokes-based turbulence models, i.e., standard \(k - \varepsilon\), standard \(k - \omega\), and shear-stress transport \(k - \omega\). Moreover, a comparison between CFD outputs and experimental data, at the inlet pressure of 7 bar, demonstrates that the standard \(k - \varepsilon\) model outperforms other turbulence models utilized in this study. The internal flow behavior is also examined for further illustration of its features via CFD. It is reported that a convergent–divergent virtual duct is formed through the streamline at the region wherein injected flow (from the inlet nozzles into the vortex chamber) swirls toward the cold orifice, resulting in an expansion. Consequently, the Mach number goes above one and temperature drops. Thus, the sudden expansions alongside free and forced vortices as well as the secondary circulation flow have a significant impact on energy separation in the VT.

Similar content being viewed by others

Abbreviations

- \(A\) :

-

Area (m2)

- \(C_{p}\) :

-

Constant pressure-specific heat capacity of air at room temperature (J kg−1 K−1)

- \(c\) :

-

Speed of sound (m s−1)

- \(E_{\text{ij}}\) :

-

Mean strain rate tensor

- \(h\) :

-

Enthalpy for unit mass (J kg−1)

- \(h_{0}\) :

-

Total enthalpy for unit mass (J kg−1)

- \(K\) :

-

Thermal conductivity (W m−1 K−1)

- \(k\) :

-

Turbulence kinetic energy (m2 s−3)

- \(M\) :

-

Mach number

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \(p\) :

-

Pressure (pa)

- \(P_{0}\) :

-

Total pressure (Pa)

- \({ \Pr }\) :

-

Prandtl number

- \(R\) :

-

Specific constant of an ideal gas (J kg−1 K−1)

- \(T\) :

-

Static temperature (K)

- \(T_{0}\) :

-

Total temperature (K)

- \(U_{\text{R}}\) :

-

Uncertainty

- \(u\) :

-

Mass-averaged velocity (m s−1)

- \(u^{{\prime }}\) :

-

Fluctuating velocity components (m s−1)

- \(c_{{1\upvarepsilon}} , \, c_{{2\upvarepsilon}} , \, c_{\upmu} , \, \sigma_{k} , \, \sigma_{\upvarepsilon}\) :

-

Constants of \(k - \varepsilon\) model

- \(\alpha , \, \alpha^{*} , \, \beta , \, \beta^{*} , \, \sigma , \, \sigma^{*} , \, \beta_{0}\) :

-

Constants of standard \(k - \omega\) model

- \(\alpha_{1} , \, \alpha_{2} , \, \beta_{1} , \, \beta_{2} , \, \beta^{*} , \, \sigma_{{{k}1}} , \, \sigma_{{{k}1}} , \, \sigma_{{\upomega1}} , \, \sigma_{{\upomega2}}\) :

-

Constants of SST \(k - \omega\) model

- \(\alpha_{k}\) :

-

Inverse effective Prandtl number for \(\varepsilon\) equation

- \(\alpha_{\upvarepsilon}\) :

-

Inverse effective Prandtl number for \(k\) equation

- \(\xi\) :

-

Cold gas mass fraction

- \(\tau\) :

-

Stress tensor

- \(\rho\) :

-

Density (kg m−3)

- \(\mu\) :

-

Dynamic viscosity (kg m−1 s−1)

- \(\nu\) :

-

Kinematic viscosity (m2 s−1)

- \(\nu_{\text{t}}\) :

-

Kinematic turbulence viscosity (m2 s−1)

- \(\varepsilon\) :

-

Turbulence dissipation rate (m2 s−3)

- \(\omega\) :

-

Angular velocity (s−1)

- \(\varOmega\) :

-

Absolute value of vorticity

- c:

-

Cold stream

- h:

-

Hot stream

- in:

-

Inlet

- eff:

-

Effective

- 0:

-

Total

- t:

-

Turbulence

- i, j, k:

-

Cartesian indices

References

Sheikholeslami M, Jafaryar M, Shafee A, Li Z. Nanofluid heat transfer and entropy generation through a heat exchanger considering a new turbulator and CuO nanoparticles. J Therm Anal Calorim. 2018;134:2295–303.

Mohd-Ghazali N, Estellé P, Halelfadl S, Maré T, Siong TC, Abidin U. Thermal and hydrodynamic performance of a microchannel heat sink with carbon nanotube nanofluids. J Therm Anal Calorim. 2019;138:937–45.

Sakhri N, Menni Y, Chamkha AJ, Lorenzini E, Kaid N, Ameur H, et al. Study of heat and mass transfer through an earth to air heat exchanger equipped with fan in South West of Algeria. Int J Heat Technol. 2019;37:689–95.

Menni Y, Azzi A, Zidani C. Use of waisted triangular-shaped baffles to enhance heat transfer in a constant temperature-surfaced rectangular channel. J Eng Sci Technol. 2017;12:3251–73.

Menni Y, Chamkha AJ, Azzi A, Zidani C, Benyoucef B. Study of air flow around flat and arc-shaped baffles in shell-and-tube heat exchangers Study of air flow around flat and arc-shaped baffles in shell-and-tube heat exchangers n.d.

Menni Y, Azzi A, Chamkha AJ. Developing heat transfer in a solar air channel with arc-shaped baffles: effect of baffle attack angle. J New Technol Mater. 2018;8:58–67.

Menni Y, Azzi A, Chamkha A. Enhancement of convective heat transfer in smooth air channels with wall-mounted obstacles in the flow path. J Therm Anal Calorim. 2019;135:1951–76.

Menni Y, Azzi A, Chamkha AJ, Harmand S. Analysis of fluid dynamics and heat transfer in a rectangular duct with staggered baffles. J Appl Comput Mech. 2019;5:231–48.

Menni Y, Chamkha AJ, Azzi A. Fluid flow and heat transfer over staggered ‘+’ shaped obstacles. J Appl Comput Mech. 2020. https://doi.org/10.22055/jacm.2018.26277.1316.

Menni Y, Chamkha A, Lorenzini G, Benyoucef B. Computational fluid dynamics based numerical simulation of thermal and thermo-hydraulic performance of a solar air heater channel having various ribs on absorber plates. Math Model Eng Probl. 2019;6:170–4.

Shadloo MS, Mahian O. Recent advances in heat and mass transfer. J Therm Anal Calorim. 2019;135:1611–5.

Menni Y, Chamkha AJ, Azzi A. Nanofluid flow in complex geometries. A review. J Nanofluids. 2019;8:893–916.

Menni Y, Chamkha AJ, Lorenzini G, Kaid N, Ameur H, Bensafi M. Advances of nanofluids in solar collectors—a review of numerical studies advances of nanofluids in solar collectors—a review of numerical studies. Math Model Eng Probl. 2019;6:415–27.

Menni Y, Azzi A, Didi F, Harmand S. Computational fluid dynamical analysis of new obstacle design and its impact on the heat transfer enhancement in a specific type of air flow geometry. Comput Therm Sci Int J. 2018;10.

Menni Y, Azzi A, Chamkha AJ, Harmand S. Effect of wall-mounted V-baffle position in a turbulent flow through a channel: analysis of best configuration for optimal heat transfer. Int J Numer Methods Heat Fluid Flow. 2018;29:3908–3937. https://doi.org/10.1108/HFF-06-2018-0270.

Menni Y, Chamkha AJ, Zidani C, Benyoucef B. Heat transfer in air flow past a bottom channel wall-attached diamond-shaped baffle—using a CFD technique. Periodica Polytech Mech Eng. 2019;63:100–12.

Menni Y, Chamkha A, Zidani C, Benyoucef B. Heat and nanofluid transfer through baffled channels in different outlet models. Math Model Eng Probl. 2019;6:21–8.

Ranque GJ. Experiences sur la detente giratoire avec productions simultanes d’un echappment d’air chand et d’un echappment d’air froid. J Phys Radium. 1933;4:112–4.

Hilsch R. The use of the expansion of gases in a centrifugal field as cooling process. Rev Sci Instrum. 1947;18:108–13.

Ahlborn B, Groves S. Secondary flow in a vortex tube. Fluid Dyn Res. 1997;21:73.

C. Gao. Experimental study on the Ranque–Hilsch vortex tube. Technische Universiteit Eindhoven; 2005.

Xue Y, Arjomandi M, Kelso R. Experimental validation of the proposed flow behaviour. Int J Refrig. 2013. https://doi.org/10.1016/j.ijrefrig.2013.04.016.

Farzaneh-Gord M, Sadi M. Improving vortex tube performance based on vortex generator design. Energy. 2014;72:492–500.

Li N, Zeng ZY, Wang Z, Han XH, Chen GM. Experimental study of the energy separation in a vortex tube. Int J Refrig. 2015. https://doi.org/10.1016/j.ijrefrig.2015.03.011.

Cebeci I, Kirmaci V, Topcuoglu U. The effects of orifice nozzle number and nozzle made of polyamide plastic and aluminum with different inlet pressures on heating and cooling performance of counter flow Ranque–Hılsch vortex tubes: an experimental investigation. Int J Refrig. 2016. https://doi.org/10.1016/j.ijrefrig.2016.07.013.

Attalla M, Ahmed H, Ahmed MS, El-wafa AA. Experimental investigation for thermal performance of series and parallel Ranque–Hilsch vortex tube systems. Appl Therm Eng. 2017;123:327–39. https://doi.org/10.1016/j.applthermaleng.2017.05.084.

Hamdan MO, Al-omari SB, Oweimer AS. Experimental study of vortex tube energy separation under different tube design. Exp Therm Fluid Sci. 2018;91:306–11. https://doi.org/10.1016/j.expthermflusci.2017.10.034.

Majidi D, Alighardashi H, Farhadi F. Best vortex tube cascade for highest thermal separation. Int J Refrig. 2017. https://doi.org/10.1016/j.ijrefrig.2017.10.006.

Kaya H, Günver F, Uluer O, Kirmaci V. Experimental study about performance analysis of parallel connected Ranque–Hilsch counter flow vortex tubes with different nozzle numbers and materials. J Heat Transf. 2018;140:112801. https://doi.org/10.1115/1.4040707.

Behera U, Paul PJ, Kasthurirengan S, Karunanithi R, Ram SN, Dinesh K, et al. CFD analysis and experimental investigations towards optimizing the parameters of Ranque–Hilsch vortex tube. Int J Heat Mass Transf. 2005;48:1961–73.

Skye HM, Nellis GF, Klein SA. Comparison of CFD analysis to empirical data in a commercial vortex tube. Int J Refrig. 2006;29:71–80.

Exair. Vortex Tubes and Spot Cooling Products. n.d.

Oliver R. Numerical prediction of primary and secondary flows in a Ranque–Hilsch vortex tube. Dublin Institute of Technology; 2008.

Dutta T, Sinhamahapatra KP, Bandyopdhyay SS. Comparison of different turbulence models in predicting the temperature separation in a Ranque–Hilsch vortex tube. Int J Refrig. 2010;33:783–92. https://doi.org/10.1016/j.ijrefrig.2009.12.014.

Bovand M, Valipour MS, Eiamsa-ard S, Tamayol A. Numerical analysis for curved vortex tube optimization. Int Commun Heat Mass Transf. 2014;50:98–107.

Liu X, Liu Z. Investigation of the energy separation effect and fl ow mechanism inside a vortex tube. Appl Therm Eng. 2014;67:494–506. https://doi.org/10.1016/j.applthermaleng.2014.03.071.

Bidwaik AS. To study the effects of design parameters on vortex tube with CFD analysis. Int J Eng Res Technol (IJERT). 2015;4:90–5.

Kandil HA, Abdelghany ST. Computational investigation of different effects on the performance of the Ranque–Hilsch vortex tube. Energy. 2015;84:207–18. https://doi.org/10.1016/j.energy.2015.02.089.

Manimaran R. Computational analysis of energy separation in a counter-flow vortex tube based on inlet shape and aspect ratio. Energy. 2016;107:17–28.

Bej N, Sinhamahapatra KP. Numerical analysis on the heat and work transfer due to shear in a hot cascade Ranque–Hilsch vortex tube. Int J Refrig. 2016;68:161–76.

Bianco V, Khait A, Noskov A, Alekhin V. A comparison of the application of RSM and LES turbulence models in the numerical simulation of thermal and flow patterns in a double-circuit Ranque–Hilsch vortex tube. Appl Therm Eng. 2016. https://doi.org/10.1016/j.applthermaleng.2016.06.095.

Zhang B, Guo X, Yang Z. Analysis on the fluid flow in vortex tube with vortex periodical oscillation characteristics. Int J Heat Mass Transf. 2016;103:1166–75. https://doi.org/10.1016/j.ijheatmasstransfer.2016.08.063.

Moraveji A, Toghraie D. Computational fluid dynamics simulation of heat transfer and fluid flow characteristics in a vortex tube by considering the various parameters. Int J Heat Mass Transf. 2017;113:432–43. https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.095.

Thakare HR, Parekh AD. Experimental investigation and CFD analysis of Ranque–Hilsch vortex tube. Energy. 2017. https://doi.org/10.1016/j.energy.2017.05.070.

Chen J, Zeng R, Zhang W, Qiu L, Zhang X. Numerical analysis of energy separation in Ranque–Hilsch vortex tube with gaseous hydrogen using real gas model. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.05.017.

Shamsoddini R, Abolpour B. A geometric model for a vortex tube based on numerical analysis to reduce the effect of nozzle number. Int J Refrig. 2018. https://doi.org/10.1016/j.ijrefrig.2018.07.027.

Bazgir A, Nabhani N, Eiamsa-ard S. Numerical analysis of flow and thermal patterns in a double-pipe Ranque–Hilsch vortex tube: influence of cooling a hot-tube. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.08.043.

Holman JP, Gajda WJ. Experimental methods for engineers, vol. 7. New York: McGraw-Hill; 2001.

Moradicheghamahi J, Sadeghiseraji J, Jahangiri M. Numerical solution of the Pulsatile, non-Newtonian and turbulent blood flow in a patient specific elastic carotid artery. Int J Mech Sci. 2018;150:393–403. https://doi.org/10.1016/j.ijmecsci.2018.10.046.

Wilcox DC. Comparison of two-equation turbulence models for boundary layers with pressure gradient. AIAA J. 1993;31:1414–21.

Menter FR. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994;32:1598–605.

ANSYS FLUENT User’s Guide. Modeling Turbulence; 2013.

Anderson JD. Modern compressible flow: with historical perspective, vol. 12. New York: McGraw-Hill; 1990.

Acknowledgements

Authors are sincerely grateful to Dr. Mohsen Davazdah Emami, the associate professor in Mechanical Engineering, and Alireza Amiriyoon, the Thermodynamic and Heat Transfer laboratory expert, at the Department of Mechanical Engineering, Isfahan University of Technology, Iran.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sadeghiseraji, J., Moradicheghamahi, J. & Sedaghatkish, A. Investigation of a vortex tube using three different RANS-based turbulence models. J Therm Anal Calorim 143, 4039–4056 (2021). https://doi.org/10.1007/s10973-020-09368-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09368-6