Abstract

In present paper has been investigated heat transfer and friction factor characteristics of non-Newtonian base fluid flow through corrugated tube that equipped with various twisted tapes (typical twisted tape (TT) and V-cut twisted tape (VTT)) under constant heat flux density. Base fluid was 0.2 wt.%. carboxymethyl cellulose (CMC) solution, according to the rheological study, the base fluid exhibited pseudoplastic (shear thinning) behavior. The experiments are performed in Reynolds number from 2400 to 6800 with two types of twisted tapes (TT and VTT) and with different twisted ratios (y = 4.5 and 6.07) and three different combinations of depth and width ratios (DR = 0.5 and WR = 0.285, DR = 0.5 and WR = 0.5, DR = 0.285 and WR = 0.5) of twisted tapes. For all experiments with increasing Reynolds number, the Nusselt number increased in while the friction factor decreased and also the maximum thermal performance factor of 1.59 achieved with the use of the VTT with (DR = 0.5 and WR = 0.285) at a twist ratio of 4.5 and Reynolds number of 2400. The new empirical correlations proposed to predict the Nusselt number, friction factor for non-Newtonian fluid flow and compared with experimental data. The results showed that satisfactory agreement between the present correlations and obtained experimental data.

Similar content being viewed by others

Abbreviations

- Cp :

-

Specific heat capacity (\( \frac{\mathrm{W}}{\mathrm{kg}.{}^{{}^{\circ}}\mathrm{C}}\Big) \)

- D:

-

Diameter of tube (mm)

- Dc :

-

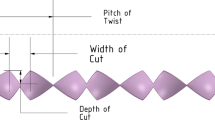

Depth of cut (mm)

- Do :

-

External diameter (mm)

- Di :

-

Internal diameter (mm)

- \( \left(\frac{\mathrm{e}}{\mathrm{D}}\right) \) :

-

Height ratio in corrugated tube

- f:

-

Friction factor

- H:

-

Pitch length of twisted tape (mm)

- havg :

-

Average heat transfer coefficient\( \left(\frac{\mathrm{W}}{{\mathrm{m}}^2.\mathrm{C}}\right) \)

- K:

-

Thermal conductivity of fluid (\( \frac{\mathrm{W}}{\mathrm{m}.{}^{{}^{\circ}}\mathrm{C}} \))

- L:

-

Tube length (mm)

- \( \overset{\cdot }{\mathrm{m}} \) :

-

Mass flow rate (\( \frac{kg}{s} \))

- Tin :

-

Inlet temperature (°C)

- Tout :

-

Outlet temperature (°C)

- t:

-

Twisted tape thickness (mm)

- \( \overset{\leftharpoonup }{\mathrm{u}} \) :

-

Average velocity (m/s)

- V:

-

Voltage (V)

- Wc :

-

Width of cut (mm)

- W:

-

Width of twisted tape (mm)

- y:

-

Twist ratio (\( \frac{H}{W} \))

- m:

-

Consistency index (Pa sn)

- n:

-

Power Law index

- Pi :

-

Inlet pressure (Pa)

- Pe :

-

Outlet pressure (Pa)

- \( \left(\frac{\mathrm{p}}{\mathrm{D}}\right) \) :

-

Pitch ratio in corrugated tube

- \( \overset{\cdot \cdot }{\mathrm{q}} \) :

-

Heat flux density (\( \frac{W}{m^2} \))

- Q1 :

-

Absorbed heat transfer (W)

- Q2 :

-

Input electrical power (W)

- Qavg :

-

Average heat transfer (W)

- R:

-

Resistance (Ω)

- Tw :

-

Wall temperature (°C)

- Tb :

-

Bulk temperature (°C)

- Re:

-

Reynolds number

- Nu:

-

Nusselt number

- Pr:

-

Prandtl number

- DR:

-

Depth ratio of cut\( \left(\frac{{\mathrm{D}}_{\mathrm{c}}}{\mathrm{W}}\right) \)

- exp:

-

Experimental

- Pre:

-

Predicted

- TT:

-

Typical twisted tape

- VTT:

-

V-cut twisted tape

- WR:

-

Width ratio of cut \( \left(\frac{{\mathrm{W}}_{\mathrm{c}}}{\mathrm{W}}\right) \)

- app:

-

Apparent

- avg:

-

Average

- f:

-

fluid

- i:

-

Internal

- MR:

-

Metzner

- o:

-

Outer

- w:

-

Wall

- ρ:

-

Density \( \left(\frac{kg}{m^3}\right) \)

- μ:

-

Dynamic viscosity\( \kern0.5em \left(\frac{\mathrm{N}.\mathrm{s}}{{\mathrm{m}}^2}\right) \)

- Φ:

-

Concentration of nanofluid, % by volume

- η:

-

Thermal performance factor

- τ:

-

Shear stress (Pa)

- \( \overset{\cdot }{\gamma } \) :

-

Shear rate (s−1)

References

Dewan A, Mahanta P, Sumithra Raju K, Suresh Kumar P (2004) Review of passive heat transfer augmentation techniques. J Power Energy 218:509–527

Eiamsa-ard S, Kiatkittipong K (2014) Heat transfer enhancement by multiple twisted tape inserts and TiO2/water nanofluid. Appl Therm Eng 70:896–924

Suri ARS, Kumar A, Maithani R (2017) Heat transfer enhancement of heat exchanger tube with multiple square perforated twisted tape inserts: experimental investigation and correlation development. Chem Eng Process Process Intensif 116:76–96

Lokanath MS (1997) Performance evaluation of full length and half length twisted tape inserts on laminar flow heat transfer in tubes. In: Proceedings of 3rd ISHMT-ASME Heat and Mass Transfer Conference, India. Tata McGraw-Hill, New Delhi, p 319–324

Saha SK, Dutta A (2001) Thermo-hydraulic study of laminar swirl flow through a circular tube fitted with twisted tapes. Transaction ASME Journal of Heat Transfer 123:417–421

Colburn AP, King WJ (1931) Heat transfer and pressure drop in empty, baffled and packed tubes. III: relation between heat transfer and pressure drop. Ind Eng Chem 23:919–923

Seymour EV (1963) A note on the improvement in performance obtainable from fitting twisted-tape turbulence promoters to tubular heat exchangers. J IChE 41:159–162

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P (2009) Convective heat transfer in a circular tube with short-length twisted tape insert. International Communications in Heat and Mass Transfer 36:365–371

Jaisankar S, Radhakrishnan TK, Sheeba KN (2008) Experimental studies on heat transfer and friction factor characteristics of forced circulation solar water heater system fitted with left-right twisted tapes. International Energy Journal 9:1–5

Sivashanmugam P, Suresh S (2007) Experimental studies on heat transfer and friction factor characteristics of turbulent flow through a circular tube fitted with helical screw-tape inserts. Chem Eng Process Process Intensif 46:1292–1298

Esmaeilzadeh E, Almohammadi H, Nokhosteen A, Motezaker A, Omrani AN (2014) Study on heat transfer and friction factor characteristics of γ-Al2O3/water through circular tube with twisted tape inserts with different thicknesses. Int J Therm Sci 82:72–83

Bhuiya MMK, Chowdhury MSU, Saha M, Islam MT (2013) Heat transfer and friction factor characteristics in turbulent flow through a tube fitted with perforated twisted tape inserts. International Communications in Heat and Mass Transfer 46:49–57

Bhuiya MMK, Chowdhury MSU, Shahabuddin M, Saha M, Memone LA (2013) Thermal characteristics in a heat exchanger tube fitted with triple twisted tape inserts. International Communications in Heat and Mass Transfer 48:124–132

Singh V, Chamoli S, Kumar M, Kumar A (2016) Heat transfer and fluid flow characteristics of heat exchanger tube with multiple twisted tapes and solid rings inserts. Chem Eng Process Process Intensif 102:156–168

Bhuiya MMK, Chowdhury MSU, Ahamed JU, Azad AK (2016) Heat transfer performance evaluation and prediction of correlation for turbulent flow through a tube with helical tape inserts at higher Reynolds number. Heat Mass Transf 52:1219–1230

Murugesan P, Mayilsamy K, Suresh S, Srinivasan PSS (2011) Heat transfer and pressure drop characteristics in a circular tube fitted with and without V-cut twisted tape insert. International Communications in Heat and Mass Transfer 38:329–334

Hasanpour A, Farhadi M, Sedighi K (2016) Experimental heat transfer and pressure drop study on typical, perforated, V-cut and 2 U-cut twisted tapes in a helically corrugated heat exchanger. International Communications in Heat and Mass Transfer 71:126–136

Eiamsa-ard S, Seemawute P, Wongcharee KH (2010) Influences of peripherally-cut twisted tape insert on heat transfer and thermal performance characteristics in laminar and turbulent tube flows. Exp Therm Fluid Sci 34:711–719

Martinez DS, Garcia A, Solano JP, Viedma A (2014) Heat transfer enhancement of laminar and transitional Newtonian and non-Newtonian flows in tubes with wire coil inserts. Int J Heat Mass Transf 76:540–548

Bharadwaj P, Khondge AD, Date AW (2009) Heat transfer and pressure drop in a spirally grooved tube with twisted tape inserts. Int J Heat Mass Transf 52:1938–1944

Mohammadiun H, Mohammadiun M, Hazbehian M, Maddah H (2016) Experimental study of ethylene glycol-based AL2O3 nanofluid turbulent heat transfer enhancement in the corrugated tube with twisted tape. Heat Mass Transf 52:141–151

Pal S, Joy S, Saha K (2015) Experimental investigation of laminar flow of viscous oil through a circular tube having integral axial corrugation roughness and fitted twisted tapes with oblique teeth. Heat Mass Transf 51:1189–1201

Ghalyanchi Langeroudi H, Javaherdeh K (2018) Investigation friction factor and heat transfer characteristics of turbulent flow through the corrugated tube inserted with typical and V-cut twisted tapes. Heat Mass Transf 54(7):1999–2008

Zhang C, Wang D, Ren K, Han Y, Zhu Y, Peng X, Deng J, Zhang X (2016) A comparative review of self-rotating and stationary twisted tape inserts in heat exchanger. Renew Sust Energ Rev 53:433–449

Liu S, Sakr M (2013) A comprehensive review on passive heat transfer enhancements in pipe exchangers. Renew Sust Energ Rev 19:64–81

Sheikholeslami M, Gorji-Bandpy M, Ganji DD (2015) Review of heat transfer enhancement methods :focus on passive methods using swirl flow devices. Renew Sust Energ Rev 49:444–469

Hasanpour A, Farhadi M, Sedighi K (2014) A review study on twisted tape inserts on turbulent flow heat exchangers: the overall enhancement ratio criteria. International Communications in Heat and Mass Transfer 55:53–62

Naik MT, Fahad SSH, Sundar LS, Singh MJ (2014) Comparative study on thermal performance of twisted tape and wire coil inserts in turbulent flow using CuO/water nanofluid. Exp Thermal Fluid Sci 57:65–76

Kareem ZS, Mohd Jaafar MN, Lazim TM, Abdullah S, Abdulwahid AF (2015) Passive heat transfer enhancement review in corrugation. Exp Thermal Fluid Sci 68:22–38

Ji WT, Jacobi AM, He YL, Tao WQ (2015) Summary and evaluation on single-phase heat transfer enhancement techniques of liquid laminar and turbulent pipe flow. Int J Heat Mass Transf 88:735–754

Vicente PG, Garcia A, Viedma A (2004) Experimental investigation on heat transfer and frictional characteristics of spirally corrugated tubes in turbulent flow at different Prandtl numbers. Int J Heat Mass Transf 47:671–681

Laohalertdecha S, Wongwises S (2011) An experimental study into the evaporation heat transfer and flow characteristics of R-134a refrigerant flowing through corrugated tubes. Int J Refrig 34:280–291

Zimparov V (2001) Enhancement of heat transfer by a combination of three-start spirally corrugated tubes with a twisted tap. Int J Heat Mass Transf 44:551–574

Laohalertdecha S, Wongwises S (2010) The effects of corrugation pitch on the condensation heat transfer coefficient and pressure drop of R-134a inside horizontal corrugated tube. Int J Heat Mass Transf 53:2924–2931

Laohalertdecha S, Wongwises S (2011) Condensation heat transfer and flow characteristics of R-134a flowing through corrugated tubes. Int J Heat Mass Transf 54:2673–2682

Barba A, Rainieri S, Spiga M (2002) Heat transfer enhancement in corrugated tube. International Communication Heat and Mass Transfer 3(29):313–322

Pethkool S, Eiamsa-ard S, Kwankaomeng S, Promvonge P (2011) Turbulent heat transfer enhancement in a heat exchanger using helically corrugated tube. International Communication Heat and Mass Transfer 38:340–347

Garcia A, Solano JP, Vicente PG, Viedma A (2012) The influence of artificial roughness shape on heat transfer enhancement: corrugated tubes, dimpled tubes and wire coils. Appl Therm Eng 35:196–201

Darzi AAR, Farhadi M, Sedighi K (2014) Experimental investigation of convective heat transfer and friction factor of Al2O3/water nano-fluid in helically corrugated tube. Exp Thermal Fluid Sci 57:188–199

Pawar SS, Sunnapwar VK (2014) Experimental and CFD investigation of convective heat transfer in helically coiled tube heat exchanger. Chem Eng Res Des 92:2294–2312

Chabbra RP, Richardson JF (2008) Non-Newtonian flow and applied rheology –engineering applications. Butterworth Heinemann –Elsevier second edition

Pimenta TA, Campos JBLM (2012) Friction losses of Newtonian and non-Newtonian fluids flowing in laminar regime in a helical coil. Exp Thermal Fluid Sci 36:194–204

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym Science 286:1173–1180. https://doi.org/10.1007/s00396-008-1882-2

Pinho FT, Whitelaw JH (1990) Flow of non-Newtonian fluids in a pipe. J Non-Newtonian Fluid Mech 34:129–144

Pilizota V, Subaric D, Lovric T (1996) Rheological properties of CMC dispersions at low temperatures. Food Technol Biotechnol 34:87–90

Metzner AB, Reed JC (1955) Flow of non-Newtonian fluids – correlation of the laminar, transition, and turbulent-flow regions. AIChE J 1:434–440

Sandall (1976) Turbulent non-Newtonian transport in a circular tube. AIChE J 22

Clapp RM (1963) Turbulent heat transfer in Pseudoplastic NonNewtonian fluids. International Developments in Heat Transfer, ASME 652:D211

Hojjat M, Etemad SGH, Bagheri R, Thibault J (2011) Convective heat transfer of non-Newtonian nanofluids through a uniformly heated circular tube. Int J Therm Sci 50:525–531

Metzner AB, Friend PS (1959) Heat transfer to turbulent nonnewtonian fluids. Ind Eng Chern J 51

Dodge AB, Metzner DW (1959) Turbulent flow of non-Newtonian systems. AICHE J 5:189–204

Clapp RM (1961) Turbulent heat transfer in pseudoplastic nonNewtonian fluids. Int Developments in Heat Transfer, ASME, Part III, Sec. A 652

Kawase Y, Wakabayashi K (1994) Friction and heat and mass transfer for turbulent pseudoplastic non-Newtonian fluids flowing in rough pipes. Can J Chem Eng 72:798–804

Beckwith TG, Marangoni RD, Lienhard JH (1990) Mechanical measurements, fifth ed. Addisone Wesley Publishing Company, New York

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Langeroudi, H.G., Javaherdeh, K. Experimental study of non-Newtonian fluid flow inside the corrugated tube inserted with typical and V-cut twisted tapes. Heat Mass Transfer 55, 937–951 (2019). https://doi.org/10.1007/s00231-018-2467-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2467-3