Abstract

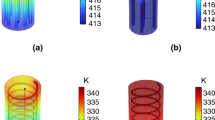

Energy storage is a critical factor in the advancement of solar thermal power systems for the sustained delivery of electricity. In addition, the incorporation of thermal energy storage into the operation of concentrated solar power systems (CSPs) offers the potential of delivering electricity without fossil-fuel backup even during peak demand, independent of weather conditions and daylight. Despite this potential, some areas of the design and performance of thermocline systems still require further attention for future incorporation in commercial CSPs, particularly, their operation and control. Therefore, the present study aims to develop a simple but efficient numerical model to allow the comprehensive analysis of thermocline storage systems aiming better understanding of their dynamic temperature response. The validation results, despite the simplifying assumptions of the numerical model, agree well with the experiments for the time evolution of the thermocline region. Three different cases are considered to test the versatility of the numerical model; for the particular type of a storage tank with top round impingement inlet, a simple analytical model was developed to take into consideration the increased turbulence level in the mixing region. The numerical predictions for the three cases are in general good agreement against the experimental results.

Similar content being viewed by others

Abbreviations

- a:

-

Fitting constant [m−1]

- aw :

-

Ratio between thermal losses area and tank volume [m−1]

- C:

-

Specific heat capacity [J/kg-K]

- d:

-

Exit diameter [m]

- D:

-

Diameter [m]

- hw :

-

Coefficient of thermal losses to the surrounding [W/m2-K]

- hv :

-

Volumetric interstitial heat transfer coefficient [W/m-K]

- k:

-

Thermal conductance [W/m-K]

- lmix :

-

Mixing length [m]

- L:

-

Height of the tank [m]

- \( \dot{m} \) :

-

Mass flow rate [m3/s]

- Prt :

-

Turbulent Prandtl number

- r:

-

Radius [m]

- t:

-

Time [s]

- T:

-

Temperature [K]

- u:

-

Velocity [m/s]

- U:

-

Average exit velocity [m/s]

- V:

-

Volume [m3]

- x:

-

Downstream distance [m]

- α:

-

Thermal diffusivity [m2/s]

- ε:

-

Porosity of the storage medium (void fraction)

- νf :

-

Kinematic viscosity [m2/s]

- νt :

-

Kinematic eddy viscosity [m2/s]

- νtotal :

-

Effective viscosity [m2/s]

- Ө:

-

Dimensionless temperature

- ρ:

-

Density [kg/m3]

- σ :

-

Standard deviation related to the spread of the profile across the centerline

- δ:

-

Distance from the centerline to the edge of the spreading [m]

- *:

-

Subscript indicating dimensionless quantities

- eff:

-

Subscript refering to the effective storage medium

- f:

-

Fluid

- m:

-

Momentum

- s:

-

Solid

- t:

-

Turbulent

- w:

-

Water

- ZEF:

-

Zone of flow establishment

References

González I, Lehmkuhl O, Pérez-Segarra C, Oliva A (2015) Dynamic thermoelastic analysis of thermocline-like storage tanks. Energy Procedia 69:850–859. https://doi.org/10.1016/j.egypro.2015.03.106

Bayón R, Rojas E (2013) Simulation of thermocline storage for solar thermal power plants: From dimensionless results to prototypes and real-size tanks. Int J Heat Mass Transf 60:713–721

Ehtiwesh I (2016) Exergetic, energetic , economic and environmental evaluation of concentrated solar power plants in Libya. http://ria.ua.pt/handle/10773/15882

Ehtiwesh I, Coelho M, Sousa ACM (2016) Exergetic and environmental life cycle assessment analysis of concentrated solar power plants. Renew Sust Energ Rev 56:145–155. https://doi.org/10.1016/j.rser.2015.11.066

Libby C (2010) Solar thermocline storage systems: preliminary design study. Report no. 1019581, EPRI, California

Tesfay M, Venkatesan M (2013) Simulation of thermocline thermal energy storage system using C. Int J Innov Appl Stud 3:354–364

Yang Z, Garimella S (2010) Thermal analysis of solar thermal energy storage in a molten-salt thermocline. Sol Energy 84:974–985

Yang Z, Garimella S (2010) Molten-salt thermal energy storage in thermoclines under different environmental boundary conditions. Appl Energy 87:3322–3329

Flueckiger S, Yang Z, Garimella S (2011) An integrated thermal and mechanical investigation of molten-salt thermocline energy storage. Appl Energy 88:2098–2105

Xu C, Wang Z, He Y, Li X, Bai F (2012) Sensitivity analysis of the numerical study on the thermal performance of a packed-bed molten salt thermocline thermal storage system. Appl Energy 92:65–75

Xu C, Wang Z, He Y, Li X, Bai F (2012) Parametric study and standby behavior of a packed-bed molten salt thermocline thermal storage system. Renew Energy 48:1–9

Xu C, Li X, Wang Z, He Y, Bai F (2013) Effects of solid particle properties on the thermal performance of a packed-bed molten-salt thermocline thermal storage system. Appl Therm Eng 57:69–80

Schumann T (1929) Heat transfer: A liquid flowing through a porous prism. J Franklin Inst 208:405–416

Zurigat Y, Liche P, Ghajar A (1991) Influence of inlet geometry on mixing in thermocline thermal energy storage. Int J Heat Mass Transf 34:115–125

Pacheco J, Showalter S, Kolb W (2002) Development of a Molten-Salt Thermocline Thermal Storage System for Parabolic Trough Plants. J So Energ Eng 124:153–159. https://doi.org/10.1115/1.1464123

Faas SE, Thorne L, Fuchs E, Gilbertsen N (1986) 10MWe solar thermal central receiver pilot plant: thermal storage subsystem evaluation – final report. Sandia National Laboratories, SAND86–8212

Mcmahan A (2006) Design & optimization of organic Rankine cycle solar-thermal power plants. Thesis, University of Wisconsin-Madison

Hoffmann J-F, Fasquelle T, Goetz V, Py X (2016) A thermocline thermal energy storage system with filler materials for concentrated solar power plants: Experimental data and numerical model sensitivity to different experimental tank scales. Appl Therm Eng 100:753–761. https://doi.org/10.1016/j.applthermaleng.2016.01.110

Murthy J (2002) Numerical Methods in Heat, Mass and Momentum Transfer. School of Mechanical Engineering, Purdue University, West Lafayette

Patankar S (1980) Numerical heat transfer and fluid flow. Series in coputational methods in mechanics and thermal sciences

Cushman-Roisin B (2014) Environmental fluid mechanics. John Wiley & Sons, Inc., New York

Wilcox D (2006) Turbulence Modeling for CFD, 3rd edn. DCW Industries, Inc., La Cañada

Van Driest E (1956) On Turbulent Flow Near a Wall. J Aeronaut Sci 23:1007–1011

Or C, Lam K, Liu P (2011) Potential core lengths of round jets in stagnant and moving environments. J Hydro Environ Res 5:81–91

Flueckiger S, Yang Z, Garimella S (2012) Thermomechanical Simulation of the Solar One Thermocline Storage Tank. J So Energ Eng 134:41014. https://doi.org/10.1115/1.4007665

Acknowledgements

The present work was sponsored by the State of Libya, under grant n° 469-2009.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• Predictions and experiments present similar trend for the time evolution.

• Inlet region deviations are most likely due to the high-level of turbulence.

• The ad-hoc proposed turbulence model leads to improved predictions.

• Predictions in relation to the experiments, have a maximum deviation of less than 12%.

Rights and permissions

About this article

Cite this article

Ehtiwesh, I.A.S., Sousa, A.C.M. Numerical model for the thermal behavior of thermocline storage tanks. Heat Mass Transfer 54, 831–839 (2018). https://doi.org/10.1007/s00231-017-2181-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2181-6