Abstract

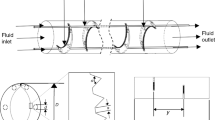

The current research deals with the experimental investigation of the heat transfer behavior and optimum relative width parameter of the multi V-down pattern perforated baffle rectangular duct. The 60° angled multi V-down perforated pattern baffle are attached on the lower duct wall having an aspect ratio (W D /H D ) of 10.0 and a Reynolds number (Re) ranging from 4000 to 9000. The experiment was conducted by varying the relative baffle width (W D /W B ) ranging from 1.0 to 6.0, relative baffle height (H B /H D ) was 0.5, relative baffle pitch (P B /H B ) was 10.0, relative hole position (O B /H B ) was 0.44, open area ratio (β O ) was 12 %. The experimental investigation shows that at a relative baffle width of 5.0 the thermal performance was maximized. Thermo-hydraulic performance (η p ) comparison shows that multi V-down pattern perforated baffle has better outcomes as compared to other baffles shaped rectangular duct.

Similar content being viewed by others

Abbreviations

- A p :

-

Surface area of heated plate (m2)

- A o :

-

Area of orifice (m2)

- C do :

-

Coefficient of discharge

- C p :

-

Specific heat of air (J/kg K)

- d h :

-

Hole diameter of perforated baffle (m)

- D hd :

-

Hydraulic diameter of duct (m)

- f :

-

Friction factor

- f rs :

-

Friction factor of roughened baffle

- f ss :

-

Friction factor smooth baffle

- h t :

-

Convective heat transfer coefficient (W/m2 K)

- H D :

-

Height of duct (m)

- H B :

-

Height of baffle (m)

- H B /H D :

-

Relative baffle height

- K a :

-

Thermal Conductivity of air (W/m K)

- L t :

-

Length of test section (m)

- L v :

-

Length of V-pattern baffle (m)

- m a :

-

Mass flow rate of air (kg/s)

- Nu :

-

Nusselt number

- Nu rs :

-

Nusselt number of rough surface

- Nu ss :

-

Nusselt number of smooth surface

- O B :

-

Hole position from base of baffle (m)

- O B /H B :

-

Relative hole position

- P B :

-

Pitch of baffle duct (m)

- P B /H B :

-

Relative pitch ratio

- (∆ p ) d :

-

Pressure drop across test section (Pa)

- (∆ p ) o :

-

Pressure drop across orifice plate (Pa)

- Q u :

-

Useful heat gain (W)

- Re :

-

Reynolds number of fluid

- T f :

-

Average temperature of air (K)

- T i :

-

Inlet temperature of air (K)

- T o :

-

Outlet temperature of air (K)

- T p :

-

Plate temperature of air (K)

- U :

-

Mean air velocity (m/s)

- V :

-

Velocity of air (m/s)

- W D /H D :

-

Duct aspect ratio

- W D :

-

Width of duct (m)

- W B :

-

Width of a single V-perforated baffle (m)

- W D /W B :

-

Relative baffle width

- SAH :

-

Solar air heater

- α a :

-

Angle of attack (°)

- β O :

-

Open area ratio (%)

- β R :

-

Ratio of orifice meter to pipe diameter, dimensionless

- ρ a :

-

Density of air (kg/m3)

- ν a :

-

Kinematic viscosity of air (m2/s)

- η :

-

Thermo-hydraulic performance

References

Kumar A, Saini RP, Saini JS (2015) Numerical optimization of effective efficiency of a discrete multi v-rib solar air channel. Heat Mass Transf 12:1–15

Kumar A, Saini RP, Saini JS (2015) Effect of roughness width ratio in discrete Multi v-shaped rib roughness on thermo-hydraulic performance of solar air heater. Heat Mass Transf 51:209–220

Thakur R, Suri ARS, Kumar S, Kumar A (2013) A review of integrated renewable energy system in power generation. Int J Mech Prod Eng Res Technol 3:79–88

Kumar A, Saini RP, Saini JS (2013) Experimental investigations on thermo-hydraulic performance due to flow-attack-angle in multiple V-ribs with gap in a rectangular duct of solar air heaters. J Sustain Energy Environ 4(1):1–7

Kumar R, Pedgopu V, Kumar A, Thakur R, Pundir A (2013) CFD based analysis heat transfer and friction characteristics of broken multiple rib roughened solar air heater duct. Int J Mech Prod Eng Res Dev 3:165–172

Kumar A, Kim MH (2015) Mathematical simulation on thermal performance of packed bed solar energy storage system. Trans Korean Hydrog New Energy Soc 26:331–338

Nasiruddin Siddiqui MHK (2001) Heat transfer augmentation in a heat exchanger tube using a baffle. Int J Heat Fluid Flow 28:318–328

Romdhane BS (2007) The air solar collectors: comparative study, introduction of baffles to favor the heat transfer. Sol Energy 81:139–149

Nie JH, Chen YT, Hsieh HT (2009) Effect of a baffle on separated convection flow adjacent to backward-facing step. Int J Therm Sci 48:618–625

Promvong P, Sripattanapipat S, Tamna S, Kwankaomeng S, Thian C (2010) Numerically investigation of laminar heat transfer in a square duct with 45 inclined baffle. Int Commun Heat Mass Transf 37:170–171

Promovong P (2010) Heat transfer and pressure drop in a duct with multiple 60 V baffle. Int Commun Heat Mass Transf 37:835–840

Tamna S, Skullong S, Thianpong C, Promvonge P (2014) Heat transfer behavior in a solar air heater duct with multiple V baffle vortex generators. Sol Energy 110:720–735

Akpinar EK, Kocyigit F (2010) Energy and energy analysis of a new flat plate solar air heater having different obstacles on absorber plates. Appl Energy 87:3438–3450

Bekele A, Mishra M, Dutta S (2014) Performance characteristics of solar air heater with surface mounted obstacles. Energy Convers Manag 85:603–611

Ko K-H, Anand NK (2003) Use of porous baffles to enhance heat transfer in a rectangular channel. Int J Heat Mass Transf 46:4191–4199

Sara ON, Pekdemir T, Yapici S (2001) Heat-transfer enhancement in a duct flow with perforated rectangular blocks. Int J Heat Fluid Flow 22:509–518

Dutta P, Hossain A (2005) Internal cooling augmentation in rectangular duct using two inclined baffles. Int J Heat Fluid Flow 26:223–232

Karwa R, Maheshwari BK, Karwa N (2005) experimental study of heat transfer enhancement in an asymmetrically heated rectangular duct with perforated baffles. Int Commun Heat Mass Transf 32:275–284

Lin CW (2006) Experimental study of thermal behavior in a rectangular duct with baffles of pores. Int Commun Heat Mass Transf 33:985–992

Karwa R, Maheshwari BK (2009) Heat transfer and friction in an asymmetrically heated rectangular duct with half and fully perforated baffles at different pitches. Int Commun Heat Mass Transf 36:264–268

Bayrak F, Oztop HF, Hepbasli A (2013) Energy and energy analysis of porous baffles solar air heater for building applications. Energy Build 57:338–345

Alam T, Saini RP, Saini JS (2014) Experimentally investigation on heat transfer enhancement due to V-shaped perforated blocks in a rectangular duct of solar air heater. Energy Convers Manag 81:374–383

Molki M, Esfahanian AH (1992) Turbulent convective mass transfer downstream of a perforated baffle blockage. Int J Heat Fluid Flow 13:116–123

Won SY, Burgess NK, Peddicord S, Ligrani PM (2004) Spatially resolved surface heat transfer for parallel rib turbulators with 45° orientations including test surface conduction analysis. J Heat Transf 126:193–201

Khanoknaiyakarn S, Kwankaomeng S, Promvonge P (2011) Thermal performance enhancement in solar air heater duct with periodically v-shaped baffles. In: IEEE explore, international conference on utility exhibition on power and energy systems issues and prospectus for Asia

Sriromreun P, Thianpong C, Promvonge P (2012) Experimental and numerical study on heat transfer enhancement in a duct with Z-shaped baffles. Int Commun Heat Mass Transf 39:945–952

Bopche SB, Tandale MS (2009) Experimental investigation on heat transfer and frictional characteristics of a turbulator roughened solar air heater duct. Int J Heat Mass Transf 52:2834–2848

Skullong S, Kwankasmeng S, Thianpong C, Promvonge P (2014) Thermal performance of turbulent flow in a solar air heater duct with rib-groove turbulators. Int Commun Heat Mass Transf 50:34–43

Shin S, Kwak JS (2008) Effect of hole shape on the heat transfer in a rectangular duct with perforated blockage walls. J Mech Sci Technol 22:1945–1951

Zhou G, Ye Q (2012) Experimental investigations of thermal and flow characteristics of curved trapezoidal winglet type vortex generators. Appl Therm Eng 37:241–248

Bekele A, Mishra M, Dutta S (2011) Effects of delta-shaped obstacles on the thermal performance of solar air heater. Adv Mech Eng 2011:1687–8132. doi:10.1155/2011/103502

Chompookham T, Thianpong C, Kwankaomeng S, Promvonge P (2010) Heat transfer augmentation in a wedge ribbed duct using winglet vortex generators. Int Commun Heat Mass Transf 37:163–169

Abene A, Dubois V, Ray ML, Ouagued A (2004) Study of a solar air flat plate collector: use of obstacles and application for the drying of grape. J Food Eng 65:15–22

Ozgen F, Esen M, Esen H (2009) Experimental investigation of thermal performance of a double-flow solar air heater having aluminum cans. Renew Energy 34:2391–2398

Thianpong C, Yongsiri K, Nanan K, Eiamsa-ard S (2012) Thermal performance evaluation of heat exchangers fitted with twisted ring turbulators. Int Commun Heat Mass Transf 39:861–868

Eiamsa-ard S, Wongcharee K, Eiamsa-ard P, Thianpong C (2010) Heat transfer enhancement in a tube using delta-winglet twisted tape insets. Appl Therm Eng 30:310–318

Chamoli S, Thakur NS (2013) Correlations for solar air heater duct with V-shaped perforated baffles as roughness elements on absorber plate. Int J Sustain Energy 35(1):1–20. doi:10.1080/14786451.2013.857318

Kumar A, Saini RP, Saini JS (2016) Numerical optimization of thermal performance of a solar air channel having discrete multi v-rib roughness on absorber plate. Heat Transf Res 47:449–469

Kumar R, Ranchan C, Muneesh S, Ashutosh S, Kumar A (2016) Experimental investigation of effect of flow attack angle on thermohydraulic performance of air flow in a rectangular channel with discrete V-pattern baffle on the heated plate. Adv Mech Eng 8:1–12

Klein SJ, McClintock A (1953) The description of uncertainties in a single sample experiments. Mech Eng 75:3–8

Author information

Authors and Affiliations

Corresponding author

Appendix: Uncertainty analysis

Appendix: Uncertainty analysis

During experimentation, lots of factors come into play which causes deviation in the values of the measured parameters from the actual value. It is essential to investigate this deviation which might occur due to carelessness during experimentation. Uncertainty analysis provides the maximum possible error in numerical digits. It is based on the random sampling during the experimentation. The uncertainty analysis tells us expected accuracy, not the exact accuracy of the system. To evaluate uncertainty involve in this experiment method suggested by Kline and McClintock [40] is used. If the value of any parameter is calculated using certain measured quantities then error in measurement of “y” (parameter) is given as follows.

where, \(\delta x_{1} ,\delta x_{2} ,\delta x_{3} , \ldots ,\delta x_{n}\) are possible error in measurement of x 1, x 2, x 3, …, x n , δ y is known as absolute uncertainty and \(\frac{{\delta_{y} }}{y}\) is known as relative uncertainty.

In the present experiment, important parameters considered for uncertainty analysis are Reynolds number, Heat transfer coefficient, Nusselt number, and friction factor. The values of measured parameters are given in Table 3.

The thermo-physical properties of air have been determined by following standard correlations:

Uncertainty associated with instruments used in various measurements of parameters in the experiment is given in Table 4.

-

1.

Uncertainty in Area of absorber plate

-

2.

Uncertainty in Area of flow

-

3.

Uncertainty in measurement of Hydraulic diameter

-

4.

Uncertainty in Area of orifice meter

-

5.

Uncertainty in density measurement

-

6.

Uncertainty in mass flow rate measurement

-

7.

Uncertainty in measurement of air velocity in channel

-

8.

Uncertainty in useful heat gain

-

9.

Uncertainty in heat transfer coefficient

-

10.

Uncertainty in Nusselt number

-

11.

Uncertainty in Reynolds Number

-

12.

Uncertainty in friction factor

The uncertainty calculation has been done on a single test run (constant Reynolds number), the uncertainty analysis for complete test run for single geometry (complete set of Reynolds number) is carried out and results are presented in Table 5 for the experimental data.

Rights and permissions

About this article

Cite this article

Kumar, R., Kumar, A., Sharma, A. et al. Experimental study of heat transfer enhancement in a rectangular duct distributed by multi V-perforated baffle of different relative baffle width. Heat Mass Transfer 53, 1289–1304 (2017). https://doi.org/10.1007/s00231-016-1901-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1901-7