Abstract

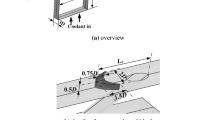

Heat transfer coefficients were measured by the improved hue detection based liquid crystal technique in a turbine blade internal cooling passage model with blockage walls. In the experiments, blockages with 9 holes of circular, wide, narrow shapes were used and for the circular shape, the number of hole of 7, 9, and 11 were tested. For all cases, the perforated area was kept same. Results showed that the staggered impingement jets increased heat transfer coefficient, however, pressure drop also increased greatly. Generally, Nusselt number ratio and the thermal performance factor decreased as Reynolds number increased. For all Reynolds numbers tested, the blockage wall with wide holes gave more uniform heat transfer coefficient and higher thermal performance factor. As the number of hole increased from 7 to 11, the distribution of heat transfer coefficient became uniform and the thermal performance factor increased.

Similar content being viewed by others

References

S. V. Ekkad, G. Pamula and S. Acharya, 2000, Influence of crossflow-induced swirl and impingement on heat transfer in an internal coolant passage of a turbine airfoil, J of heat transfer, 122 587–597.

G. Pamula, S. V. Ekkad and S. Acharya, 2000, Influence of cross-flow induced swirl and impingement on heat transfer in a two-pass channel connected by two rows of holes, ASME paper 2000-GT-0235

S. W. Moon and S. C. Lau, 2003, Heat transfer between blockages with holes in a rectangular channel, J. of heat transfer, 125 587–594.

S. C. Lau, J. Cervantes, J. C. Han, R. J. Rudolph and K. Flannery, 2003, Measurements of wall heat (mass) transfer for flow through blockages with round and square holes in a wide rectangular channel, Int. J. of heat and mass transfer, 46 3991–4001.

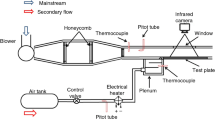

S. Shin and J. S. Kwak, 2007, Improvement of the hue detection based transient liquid crystals technique, AICFM 2007-027, Jeju, Korea.

ISO, 2004, Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full-Part 4: Venturi tubes, ISO 5167-4.

F. P. Incropera and D. P. DeWitt, 2001, Heat and mass transfer, 5th edition, John Wiley & Sons, INC.

S. Wagner, M. Kotulla, P. Ott, B. Weigand, and V. von Wolfersdorf, 2005, The transient liquid crystal technique: Influence of surface curvature and finite wall thickness, J. of Turbomacinery, 127 175–182.

P. F. Dunn, 2005, Measurement and data analysis for engineering and science, Mcgraw-Hill, Inc.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was presented at the 9th Asian International Conference on Fluid Machinery (AICFM9), Jeju, Korea, October 16–19, 2007.

Rights and permissions

About this article

Cite this article

Shin, S., Kwak, J.S. Effect of hole shape on the heat transfer in a rectangular duct with perforated blockage walls. J Mech Sci Technol 22, 1945–1951 (2008). https://doi.org/10.1007/s12206-008-0736-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-008-0736-7