Abstract

Three-dimensional freezing of water around a coolant carrying horizontal tube placed in an adiabatic rectangular cavity partially including copper foils is investigated numerically and by experiment. Both, enhancement of freezing and a uniform freezing rate are achieved. The present numerical analysis predicts well the transient solid fraction found by experiments.

Similar content being viewed by others

Abbreviations

- c :

-

Specific heat

- C :

-

Coefficient in the PCM flow resistance (=−10−6, Eq. 8)

- d 1 :

-

Diameter of the domain 1 without copper foils

- d i :

-

Inner diameter of the tube (=17.05 mm)

- d o :

-

Outer diameter of the tube (=19.05 mm)

- DTF :

-

Temperature range (0.05 °C) in the mushy zone (0 < f s < 1)

- f :

-

Mass fraction

- F :

-

Flow resistance per unite area perpendicular to the flow direction (Eq. 8)

- h f :

-

Latent heat of freezing

- H :

-

Height/width of the rectangular cavity (=12 cm)

- k :

-

(effective) Thermal conductivity

- L :

-

Tube length (=40 cm)

- n :

-

Copper foil number

- p :

-

Copper foil thickness (=35 μm)

- P :

-

Coefficient in the flow resistance of the copper foils porous layer (Eq. 9)

- r 1 :

-

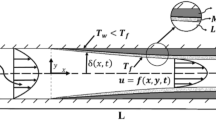

Distance in the domain 1 (=(d 1 − d o )/2, without copper foils, see Fig. 1)

- t :

-

Time

- T :

-

Temperature

- T ph :

-

Freezing temperature (=0 °C)

- U :

-

x-Component velocity

- v :

-

y-Component velocity

- V PCM :

-

PCM volume \( ( = L[\gamma_{f2} (H^{2} - \pi d_{1}^{2} /4) + \pi \gamma_{f1} (d_{1}^{2} - d_{o}^{2} )4]) \)

- V bare :

-

Bare volume of the cavity (\( = L[H^{2} - \pi d_{o}^{2} /4],\,\gamma {}_{f1} = \gamma_{f2} = 1 \) in V PCM)

- w :

-

z-Component velocity

- w m :

-

Mean velocity of the coolant in the tube (=0.0245 m/s)

- x :

-

Horizontal coordinate

- y :

-

Vertical coordinate

- z :

-

Axial coordinate

- γ:

-

Volume fraction

- γ f :

-

Porosity, PCM volume fraction (i.e., = γ s+γℓ = 1 − γ c )

- ρ:

-

Density

- υ:

-

Kinematic viscosity

- 1:

-

Domain 1

- 2:

-

Domain 2

- c:

-

Copper

- clt:

-

Coolant

- f:

-

PCM

- ini:

-

Initial

- inlt:

-

Inlet

- ℓ:

-

Liquid (water)

- s :

-

Solid (ice)

- x :

-

x-Direction

- y :

-

y-Direction

- z :

-

z-Direction

References

Sugawara M, Komatsu Y, Beer H (2008) Melting and freezing around a horizontal cylinder placed in a square cavity. Heat Mass Transf 45:83–92

Sugawara M, Onodera T, Komatsu Y, Tago M, Beer H (2008) Freezing of water saturated in aluminum wool mats. Heat Mass Transf 44:835–843

Saito A, Utaka Y, Nagakubo S, Katayama K (1983) Study of heat transfer for latent heat storage (in Japanese). Trans Jpn Soc Mech Eng 49–443:1485–1492

Bathelt AG, Van Buren PD, Viskanta R (1981) Heat transfer during solidification around a cooled horizontal cylinder. AIChE Symp Ser 75–189:103–111

Prusa J, Yao LS (1984) Melting around a horizontal heated cylinder: part II—numerical solution for isothermal boundary condition. ASME J Heat Transf 106:469–474

Sasaguchi K, Imura H, Furusho H (1986) Heat transfer characteristics for latent heat storage system with finned tube (1st report: experimental study for solidification and melting processes) (in Japanese). Trans Jpn Soc Mech Eng (Ser B) 52(473):159–166

Sasaguchi K, Imura H, Furusho H (1986) Heat transfer characteristics for latent heat storage system with finned tube (2nd report : comparison of numerical and experiment for solidification processes) (in Japanese). Trans Jpn Soc Mech Eng (Ser B) 52(473):167–173

Rieger H, Beer H (1986) The melting process of ice inside a horizontal cylinder: effects of density anomaly. ASME J Heat Transf 108:166–173

Padmanabhan PV, Murthy MVK (1986) Outward phase change in a cylindrical annulus with axial fins on the inner tube. Int J Heat Mass Transf 29–12:1855–1868

Zhang Y, Faghri A (1995) Heat transfer enhancement in latent heat thermal energy storage system by using the internally finned tube. Int J Heat Mass Transf 39–15:3165–3173

Esen M, Ayhan T (1996) Development of a model compatible with solar assisted cylindrical energy storage tank and variation of stored energy with time for different phase-change materials. Energy Convers Manage 37(12):1775–1785

Chung JD, Lee JS, Yoo H (1997) Thermal instability during the melting process in an isothermally heated horizontal cylinder. Int J Heat Mass Transf 40–16:3899–3907

Sasaguti K, Kusano K, Viskanta R (1997) A numerical analysis of solid–liquid phase change heat transfer around a single and two horizontal, vertically spaced cylinders in a rectangular cavity. Int J Heat Mass Transf 40–6:1343–1354

Esen M, Durmus A, Durmus A (1998) Geometric design of solar-aided latent heat store depending on various parameters and phase change materials. Sol Energy 62(1):19–28

Esen M (2000) Thermal performance of a solar-aided latent heat store used for space heating by heat pump. Sol Energy 69(1):15–25

Sari A, Kaygusuz K (2001) Thermal energy storage system using stearic acid as a phase change material. Sol Energy 71:365–376

Sari A, Kaygusuz K (2002) Thermal performance of a eutectic mixture of lauric and stearic acids as PCM encapsulated in the annulus of two concentric pipes. Sol Energy 72:493–504

Fukai J, Hamada Y, Morozumi Y, Miyatake O (2003) Improvement of the thermal characteristics of latent heat thermal energy storage units using carbon-fiber brushes. Int J Heat Mass Transf 46:4513–4525

Shatikian V, Ziskind G, Letan R (2005) Numerical investigation of a PCM-based heat sink with internal fins. Int J Heat Mass Transf 48:3689–3706

Trp A (2005) An experimental and numerical investigation of heat transfer during technical grade paraffin melting and solidification in a shell-and-tube latent thermal energy storage unit. Sol Energy 79:648–660

Kayansayan N, Acar MA (2006) Ice formation around a finned-tube heat exchanger for cold thermal energy storage. Int J Therm Sci 45:405–418

Ermis K, Erek A, Dincer I (2007) Heat Transfer analysis of phase change process in a finned-tube thermal energy storage system using artificial neural network. Int J Heat Mass Tranf 50:3163–3175

Agyenim F, Eames P, Smyth M (2009) A comparison of heat transfer enhancement in a medium temperature thermal energy storage heat exchanger using fins. Sol Energy 83:1509–1520

Sugawara M, Beer H (2009) Numerical analysis for freezing/melting around vertically arranged four cylinders. Heat Mass Transf 45:1223–1231

Sugawara M, Komatsu Y, Makabe T, Beer H (2010) Three dimensional freezing around a coolant-carrying tube. Heat Mass Transf 46:1307–1314

Sugawara M, Komatsu Y, Beer H (2010) Three dimensional melting of ice around a liquid-carrying tube. Heat Mass Transf 47:139–145

Hand book of air conditioning system design, part 4(1965), McGrw hill book company, pp 32–35

Tanaka M, Chisaka F (1990) Effective thermal conductivity of discontinuous and continuous solid system. Kagaku Kougaku (in Japanese) 16:168–173

Acknowledgments

The authors wish to acknowledge support for this study by the technical official T. Fujita.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sugawara, M., Komatsu, Y., Onodera, D. et al. Three-dimensional freezing of water in a copper foils porous layer around a coolant-carrying tube. Heat Mass Transfer 48, 1847–1854 (2012). https://doi.org/10.1007/s00231-012-1030-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-012-1030-x