Abstract

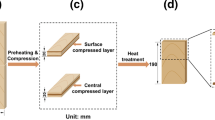

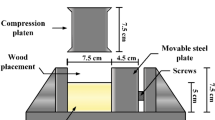

Low-density hybrid poplar wood (Populus deltoides × Populus trichocarpa) was densified by mechanical compression under saturated steam, superheated steam, and transient conditions at temperature levels of 150, 160, and 170°C. Furthermore, compression of wood under saturated steam conditions at 170°C, followed by post-heat-treatment at 200°C for 1, 2, and 3 min, was performed. To determine the influence of compression treatment on the set recovery, specimens were subjected to five cycles of water soaking and drying. Modulus of rupture (MOR) and modulus of elasticity (MOE) of specimens compressed under saturated steam conditions at 170°C and post-heat-treated at 200°C were determined in the dry condition and after five soak/dry cycles. Higher temperature of the compression treatment resulted in lower equilibrium moisture content, while the steam conditions during the treatment and the post-heat-treatment did not have significant effect. Furthermore, the highest degree of densification was obtained in specimens compressed under saturated steam conditions at 170°C and post-heat-treated at 200°C. The steam condition and temperature influenced the set recovery of compressive deformation. Reduced hygroscopicity does not necessarily imply reduced set recovery. The results established that considerable fixation of compressive deformation can be obtained by compressing the wood in a saturated steam environment and by post-heat-treatment at 200°C. The short heat-treatment had no influence on MOR or MOE, but soaking/drying treatments caused a decrease in the MOR and MOE.

Similar content being viewed by others

References

Blomberg J, Persson B, Blomberg A (2005) Effects of semi-isostatic densification of wood on the variation in strength properties with density. Wood Sci Technol 39:339–350

Blomberg J, Persson B, Bexell U (2006) Effects of semi-isostatic densification on anatomy and cellshape recovery on soaking. Holzforschung 60:322–331

Dwianto W, Morooka T, Norimoto M, Kitajima T (1999) Stress relaxation of Sugi (C. japonica D. Don) wood in radial compression under high temperature steam. Holzforschung 53(5):541–546

Esteves B, Marques AV, Domingos I, Pereira H (2007) Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globules) wood. J Wood Sci Technol 41:193–207

Hillis WE (1984) High temperature and chemical effects on wood stability. Part 1. General considerations. Wood Sci Technol 18:281–293

Hsu WE, Schwald W, Schwald J, Shields JA (1988) Chemical and physical changes required for producing dimensionally stable wood-based composites. Wood Sci Technol 22:281–289

Inoue M, Norimoto M, Tanahashi M, Rowell MR (1993) Steam or heat fixation of compressed wood. Wood Fiber Sci 25(3):224–235

Inoue M, Sekino N, Morooka T, Norimoto M (1996) Dimensional stabilization of wood composites by steaming I. Fixation of compressed wood by pre-steaming. In: Proceedings of third pacific rim bio-based composites symposium, Kyoto, pp 240–248

Inoue M, Sekino N, Morooka T, Rowell RM, Norimoto M (2008) Fixation of compressive deformation in wood by pre-steaming. J Trop For Sci 20(4):273–281

Kollmann FP, Cote WA (1968) Principles of wood science and technology I. solid wood. Springer, Heidelberg

Kollmann FP, Kuenzi EW, Stamm AJ (1975) Principles of Wood Science and Technology. Vol II: Wood based materials. Springer, Heidelberg

Kutnar A, Kamke FA (2010) Compression of wood under saturated steam, superheated steam, and transient conditions at 150°C, 160°C and 170°C. Wood Sci Technol, published online Oct. 8, 2010; doi:10.1007/s00226-010-0380-0

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43(1):57–68

Lenth CA, Kamke FA (2001a) Moisture dependent softening behavior of wood. Wood Fiber Sci 33(3):492–507

Lenth CA, Kamke FA (2001b) Equilibrium moisture content of wood in high-temperature pressurized environments. Wood Fiber Sci 33(1):104–118

Metsä-Kortelainen S, Antikainen T, Viitaniemi P (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170°C, 190°C, 210°C and 230°C. Holz Roh- Werkst 64(3):192–197

Morsing N (2000) Densification of wood—the influence of hygrothermal treatment on compression of beech perpendicular to the grain. Department of structural engineering and materials technical university of Denmark, Series R, 79, p 138

Navi P, Heger F (2004) Combined densification and thermo-hydro- mechanical processing of wood. Materials Research Society, Bulletin, pp 332–336

Reynolds MS (2004) Hydro-thermal stabilization of wood-based materials. Master Thesis. Virginia Tech, Blacksburg, Virginia, p 155

Santos JA (2000) Mechanical behavior of Eucalyptus wood modified by heat. Wood Sci Technol 34:39–43

Statgraphics Plus version 5.0 (2000) Manugistics, Inc., Rockville, MD

Wolcott MP, Shutler EL (2003) Temperature and moisture influence on compression—recovery behavior of wood. Wood Fiber Sci 35(4):540–551

Acknowledgments

The project was supported by the National Research Initiative of the USDA Cooperative State Research, Education and Extension Service, grant number 2006-35504-17444 and USDA Wood Utilization Research Center Special Grant number 2008-34158-19302.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kutnar, A., Kamke, F.A. Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci Technol 46, 953–964 (2012). https://doi.org/10.1007/s00226-011-0456-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-011-0456-5