Abstract

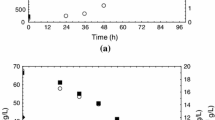

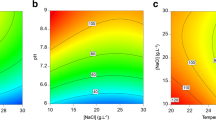

This study aimed at optimising the cultivation conditions for the production of carotenoids by Sporidiobolus salmonicolor (CBS 2636) in a bioreactor. The maximum content of total carotenoids in the full factorial design 2² was 3131.3 μg/L in synthetic medium with 80 g/L of glucose, 15 g/L of peptone, 5 g/L of malt extract, aeration of 1.5 vvm, agitation of 180 rpm, initial pH of 4.0 at 25 °C. In the kinetic study, we could observe that the bioproduction of carotenoids is associated with cell growth in the exponential phase, and the average specific growth (μ) in bioreactor is 0.046 h−1 with a maximum yield of 0.19 g cells/L h. The maximum yield of carotenoids (60.0 μg/Lh) is observed at 50-h bioproduction. The conversion factor for total organic carbon (TOC) in cells (YX/SCOT) was 2.97 g/g (0–50 h) and 0.254 g/g (50–100 h), the conversion factor glucose into cells (YX/Sglicose) was 0.168 g/g (0–100 h). The specific production of carotenoids (YP/X) was 390 μg of carotenoids per gram of cells, the conversion factor of carbon in the product (YP/SCOT) was 107.8 μg/g (0–50 h) and 34.4 μg/g (50–100 h), whereas the factor YP/Sglicose was 69.59 μg/g. The agitation and aeration provided better homogeneity in the culture medium, and hence greater availability of nutrients and oxygen, leading to higher production of carotenoids.

Similar content being viewed by others

References

Das A, Yoon S, Lee S, Kim J, Oh D, Kim S (2007) An update on microbial carotenoid production: application of recent metabolic engineering tools. Appl Microbiol Biotechnol 77:505–512

Botella-Pavía P, Rodríguez-Concepción M (2006) Carotenoid biotechnology in plants for nutritionally improved foods. Physiol Plant 126:369–381

El-Agamey A, Lowe GM, Mcgarvey DJ, Mortensen A, Phillip DM, Truscott G, Young AJ (2004) Carotenoid radical chemistry and antioxidant/pro-oxidant properties. Arch Biochem Biophys 430:37–48

Aksu Z, Eren AT (2007) Production of carotenoids by isolated yeast of Rhodotorula glutinis. Biochem Eng J 35:107–113

Krinsky NI (2001) Carotenoids as antioxidants. Nutrition 17:815–817

Gu Z, Deming C, Yongbin H, Zhigang C, Feirong G (2008) Optimization of carotenoids extraction from Rhodobacter sphaeroides. Food Sci Technol 14:1082–1088

Demming-Adams B, Gilmore AM, Adams WW (2006) In vivo functions of carotenoids in higher plants. Faseb J 10:403–412

Aguilar CP, González M, Cifuentes AS, Silva M (2004) Growth and accumulation of total carotenoids in two strains of Dunaliella salina Teod. (Chlorophyceae) from the northern and central coast of Perú. J Chilean Chem Soc 49:69–74

Fazeli MR, Tofighi H, Samadi N, Jamalifar H (2006) Effects of salinity on b-carotene production by Dunaliella tertiolecta DCCBC 26 isolated from Urmia salt lake, North of Iran. Bioresour Technol 97:2453–2456

Po-Fung I, Feng C (2005) Production of astaxanthin by the green microalga Chlorella zofingiensis in the dark. Process Biochem 40:733–738

García-González M, Moreno J, Manzano JC, Florencio FJ, Guerrero MG (2005) Production of Dunaliella salina biomass rich in 9-cis-β-carotene and lutein in a closed tubular photobioreactor. J Biotechnol 115:81–90

Dufossé L, Galaup P, Yaron A, Arad SM, Blanc P, Murthy KNC (2005) Microorganisms and microalgae as sources of pigments for food use: a scientific oddity or an industrial reality. Trends Food Sci Technol 16:389–406

Johnson EA, Schroeder WA (1995) Microbial carotenoids. Adv Biochem Eng Biotechnol 11:297–326

Goodwin TW (1980) The biochemistry of the carotenoids. Chapman & Hall, London

Hu ZC, Zheng YG, Wang Z, Shen YC (2006) pH control strategy in astaxanthin fermentation bioprocess by Xanthophyllomyces dendrorhous. Enzyme Microb Technol 39:586–590

Park PK, Kim EY, Chu KH (2007) Chemical disruption of yeast cells for the isolation of carotenoid pigments. Sep Purific Technol 53:148–152

Tinoi J, Rakariyatham N, Deming RL (2005) Simplex optimization of carotenoid production by Rhodotorula glutinis using hydrolyzed mung bean waste flour as substrate. Process Biochem 40:2551–2557

Davoli P, Mierau V, Weber RWS (2004) Carotenoids and fatty acids in red yeasts Sporobolomyces roseus and Rhodotorula glutinis. Appl Biochem Microbiol 40:392–397

Razavi SH, March I (2006) Effect of temperature and pH on the growth kinetics and carotenoid production by Sporobolomyces ruberrimus H110 using technical glycerol as carbon source. Iranian J Chem Eng 23:59–64

Maldonade IR, Rodriguez-Amaya DB, Scamparini ARP (2008) Carotenoids of yeasts isolated from the Brazilian ecosystem. Food Chem 107:145–150

Valduga E, Valerio A, Treichel H, Di Luccio M, Furigo AJ (2008) Study of the bio-production of carotenoids by Sporidiobolus salmonicolor (CBS 2636) using pre-treated agro-industrial substrates. J Chem Technol Biotechnol 83:1267–1274

Lim GB, Lee SY, Lee EK, Haam SJ, Kim WS (2002) Separation of astaxanthin from red yeast Phaffia rhodozyma by supercritical carbon dioxide extraction. Biochem Eng J 11:181–187

Liu YS, Wu JY, Ho KP (2006) Characterization of oxygen transfer conditions and their effects on Phaffia rhodozyma growth and carotenoid production in shake-flask cultures. Biochem Eng J 27:331–335

Fang TJ, Wang JM (2002) Extractability of astaxanthin in a mixed culture of a carotenoid over-producing mutant of Xanthophyllomyces dendrourhous and Bacillus circulans in two-stage batch fermentation. Process Biochem 37:1235–1245

Ramírez J, Gutierrez H, Gschaedler A (2001) Optimization of astaxanthin production by Phaffia rhodozyma through factorial design and response surface methodology. J Biotechnol 88:259–268

Valduga E, Tatsch PO, Tiggemann L, Zeni J, Colet R, Cansian JM, Treichel H, Di Luccio M (2009) Evaluation of the conditions of carotenoids production in a synthetic medium by Sporidiobolus salmonicolor (CBS 2636) in a bioreactor. Int J Food Sci Technol 44:2445–2451

Valduga E, Valerio A, Tatsch PO, Treichel H, Furigo AJ, Di Luccio M (2009) Assessment of cell disruption and carotenoids extraction from Sporidiobolus salmonicolor (CBS 2636). Food Bioproc Technol 2:234–238

Hiss H (2001) Cinética dos Processos Fermentativos. Editora Edgard Blücher Ltda, São Paulo

Bailey JE, Ollis DF (1986) Biochemical engineering fundamentals. McGraw-Hill Book Company, New York

Davies BH (1976) Carotenoid. Chemistry and biochemistry of plant pigments. Academic Press, New York

Silva C, Cabral JMS, Keulen FV (2004) Isolation of a β-total carotenoids over-producing soil bacterium, Sphingomonas sp. Biotechnol Lett 26:257–262

Association of Official Analytical Chemists, AOAC (1995) Official methods of analysis of the association of the analytical chemists, Washington, 1995

Miller GL (1959) Use of dinitrosalicyclic acid reagent for determination of reducing sugar. Analytical Chem 31:426–428

Buzzini P, Innocenti M, Turchetti B, Libkind D, van Broock M, Mulinacci N (2007) Carotenoid profiles of yeasts belonging to the genera Rhodotorula, Rhodosporidium, Sporobolomyces, and Sporidiobolus. Can J Microbiol 53:1024–1031

Choudari SM, Singhal R (2008) Media optimization for the production of b-carotene by Blakeslea trispora: a statistical approach. Bioresour Technol 99:722–730

Valduga E, Valerio A, Treichel H, Furigo AJ, Di Luccio M (2009) Optimization of the bio-production of total carotenoids by Sporidiobolus salmonicolor (CBS 2636) using response surface technique. Food Bioproc Technol 2:415–421

Garbayo I, Vílchez C, Nava-Saucedo JE, Barbotin JN (2003) Nitrogen, carbon and light-mediated regulation studies of carotenoid biosynthesis in immobilized mycelia of Gibberella fujikuroi. Enzyme Microb Technol 33:629–634

Liu YS, Wu JY (2007) Optimization of cell growth and carotenoid production of Xanthophyllomyces dendrorhous through statistical experiment design. Biochem Eng J 36:182–189

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Valduga, E., Schwartz, C.R.M., Tatsch, P.O. et al. Evaluation of aeration and substrate concentration on the production of carotenoids by Sporidiobolus salmonicolor (CBS 2636) in bioreactor. Eur Food Res Technol 232, 453–462 (2011). https://doi.org/10.1007/s00217-010-1410-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1410-8