Abstract

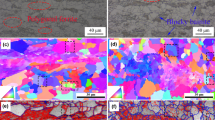

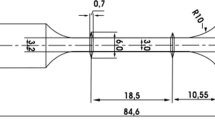

This work is motivated by the fact that the microstructures of nickel-based alloy forged parts influenced by hot deformation have a great impact on the mechanical properties of their final parts. In this paper, a simplified 2D half-symmetry FE model embedded with the JMAK model is developed to predict the deformation characteristics and microstructure behaviors of an IN718 aeroengine drum in hot forging procedure and then verified by experiments. Moreover, based on two evaluation indexes, the distribution uniformities and general levels of effective strain, strain rate, temperature, dynamic recrystallization, and grain size within the forged IN718 alloy drum are analyzed quantitatively. The results suggest that unlike strain rate and grain size, the maximum values of effective strain, temperature, and dynamic recrystallization volume fraction are located at the internal wall of the forged drum, and their distribution uniformities become worse with the increment of forging strokes. Besides, the Xavg and davg show an opposite evolution trend as increasing forging strokes, which are mainly related to the increments of εavg and Tavg as well as the grain refinement of dynamic recrystallization.

Similar content being viewed by others

References

Wang JG, Liu D, Yuan YJ, Li XL, Yang YH, Wang HP, Wang H, Huang JH, Zhang Z (2022) Deformation characteristic and microstructure evolution of GH4169 alloy induced by axial upsetting and axial rotary forging. Mater Charact 191:112136

Yin Q, Wen ZX, Wang JD, Lian YD, Lu GX, Zhang CJ, Yue ZF (2022) Microstructure characterization and damage coupled constitutive modeling of nickel-based single-crystal alloy with different orientations. Mater Sci Eng A 853:143761

Peng X, Liang YL, Qin XM, Gu JB (2022) The effect of ultrasonic surface rolling process on tension-tension fatigue limit of small diameter specimens of Inconel 718 superalloy. Int J Fatigue 162:106964

Le W, Chen Z, Yan K, Zhao YN, Zhang H (2022) Hot deformation and microstructure evolution of selective laser melted 718 alloy pre-precipitated with δ phase. Mater Sci Eng A 851:143633

Bartolomeis AD, Newman ST, Jawahir IS, Biermann D, Shokrani A (2021) Future research directions in the machining of Inconel 718. J Mater Process Technol 297:117260

Sun B, Zhang TB, Song L, Zhang L (2022) Microstructural evolution and dynamic recrystallization of a nickel-based superalloy PM EP962NP during hot deformation at 1150 °C. J Mater Res Technol 18:1436–1449

Tan YB, Ma YH, Zhao F (2018) Hot deformation behavior and constitutive modeling of fine grained Inconel 718 superalloy. J Alloy Compd 741:85–96

Kolmogorov AN (1937) On the statistical theory of the crystallization of metals. Bull Acad Sci Ussr Math Ser 1(3):355–359

Jafarian F, Ciaran MI, Umbrello D, Arrazola PJ, Filice L, Amirabadi H (2014) Finite element simulation of machining Inconel 718 alloy including microstructure changes. Int J Mech Sci 88:110–121

Geng PH, Qin GL, Zhou J, Li TY, Ma NS (2021) Characterization of microstructures and hot-compressive behavior of GH4169 superalloy by kinetics analysis and simulation. J Mater Process Technol 288:116879

Azarbarmas M, Khafri MA (2017) Dynamic recrystallization and texture modeling of IN718 superalloy. Model Simul Mater Sci Eng 25(7):075001

Lotfi M, Farid AA, Akbari J, Sharif S, Mohruni AS (2022) Evaluation of surface integrity when drilling Inconel 718 through experimental measurement and finite element analysis. Int J Adv Manuf Technol 119(7):4237–4248

Xia YX, Shu XD, Zhu DB, Pater Z, Bartnicki J (2021) Effect of process parameters on microscopic uniformity of cross wedge rolling of GH4169 alloy shaft. J Manuf Process 66:145–152

Li CM, Tan YB, Zhao F (2018) Finite element simulation and process optimization of microstructure evolution in the formation of Inconel 718 alloy bolts. Mater Res Express 6(2):026578

Chamanfar A, Valberg HS, Templin B, Plumeri JE, Misiolek WZ (2019) Development and validation of a finite-element model for isothermal forging of a nickel-base superalloy. Materialia 6:100319

Razali MK, Joun MS (2021) A new approach of predicting dynamic recrystallization using directly a flow stress model and its application to medium Mn steel. J Mater Res Technol 11:1881–1894

Lotfi M, Amini S, Akbari J (2020) Surface integrity and microstructure changes in 3D elliptical ultrasonic assisted turning of Ti–6Al–4V: FEM and experimental examination. Tribol Int 151:106492

Mirkoohi E, Li DS, Garmestani H, Liang SY (2021) Residual stress modeling considering microstructure evolution in metal additive manufacturing. J Manuf Process 68:383–397

Loyda A, Reyes LA, Muñoz GMH, Castillo FAG, Robledo PZ (2018) Influence of the incremental deformation during rotary forging on the microstructure behaviour of a nickel-based superalloy. Int J Adv Manuf Technol 97(5):2383–2396

Quan GZ, Pan J, Zhang ZH (2016) Phase transformation and recrystallization kinetics in space-time domain during isothermal compressions for Ti-6Al-4V analyzed by multi-field and multiscale coupling FEM. Mater Des 94:523–535

Gujrati R, Gupta C, Jha JS, Mishra S, Alankar A (2019) Understanding activation energy of dynamic recrystallization in Inconel 718. Mater Sci Eng A 744:638–651

Singh SN, Chowdhury S, Nirsanametla Y, Deepati AK, Prakash C, Singh S, Wu LY, Zheng HY, Pruncu C (2021) A comparative analysis of laser additive manufacturing of high layer thickness pure Ti and Inconel 718 alloy materials using finite element method. Materials 14(4):876

Yang XW, Li WY, Li J, Ma TJ, Guo J (2015) FEM analysis of temperature distribution and experimental study of microstructure evolution in friction interface of GH4169 superalloy. Mater Des 84:133–143

Luo SY, Wang Q, Zhang P, Li J, Liu QL (2020) Effect of friction conditions on phase transformation characteristics in hot forging process of Ti-6Al-4V turbine blade. J Mater Res Technol 9(2):2107–2115

Xue X, Shen GJ, Wu XQ, Xiong YLZ, Liao J, Bai HB (2022) Thermo-mechanical performances of elastic–porous materials with metallic wire mesh structures. Compos Struct 297:115918

Rajeev GP, Kamaraj M, Bakshi SR (2019) Comparison of microstructure, dilution and wear behavior of Stellite 21 hardfacing on H13 steel using cold metal transfer and plasma transferred arc welding processes. Surf Coat Technol 375:383–394

Zhao B, Khader I, Liu H, Zhou T, Konrath G, Kailer A (2021) Tribological characterization of an alumina-based composite in dry sliding contact against laser-heated and unheated Inconel 718. Tribol Int 155:106773

Öztürk E (2022) FEM and statistical-based assessment of AISI-4140 dry hard turning using micro-textured insert. J Manuf Process 81:290–300

Reyes LA, Páramo P, Zamarripa AS, Garza M, Mata MPG (2016) Influence of processing parameters on grain size evolution of a forged superalloy. J Mater Eng Perform 25(1):179–187

Loyda A, Muñoz GMH, Reyes LA, Robledo PZ (2016) Microstructure modeling of a Ni-Fe-based superalloy during the rotary forging process. J Mater Eng Perform 25(6):2128–2137

Luo SY, Yao JN, Zou GM, Li J, Jiang J, Yu FP (2020) Transformation characteristics of temperature and phases within Ti-6Al-4V aeroengine drum in hot forging and air cooling procedures. J Mater Res Technol 9(4):8235–8244

Luo SY, Zhu DH, Qian DS, Hua L, Yan SJ, Zhang JJ (2016) Effects of friction model on forging process of Ti-6Al-4V turbine blade considering the influence of sliding velocity. Int J Adv Manuf Technol 82(9):1993–2002

Availability of data and material

Data are available from the corresponding author on request.

Code availability

Not applicable.

Funding

This work was supported by the Hubei Provincial Natural Science Foundation of China (Grant nos. 2020CFB115 and 2020CFB112).

Author information

Authors and Affiliations

Contributions

Shiyuan Luo: conceptualization, methodology, software, and writing—original draft. Kai Yan: investigation, validation, and writing—original draft. Jia Li: validation and writing—original draft. Guangming Zou: data curation and writing—review and editing. Po Zhang: data curation and writing—review and editing. Liangcai Zeng: supervision and writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors consent to the publication of the manuscript in this journal.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, S., Yan, K., Li, J. et al. Numerical analysis on the deformation characteristics and microstructure behaviors of forged IN718 aeroengine drum. Int J Adv Manuf Technol 126, 3749–3764 (2023). https://doi.org/10.1007/s00170-023-11392-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11392-3