Abstract

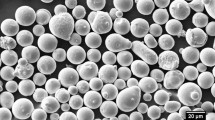

For coating deposition and additive manufacturing by cold spray, supersonic de Laval nozzles are traditionally used. The application of other configurations of the prechamber-nozzle units allows for the expansion of the technological capabilities of cold spray. In particular, the use of an ejector nozzle allows utilizing an open-type powder feeder, which does not require maintaining high pressure inside itself. In the present paper, for the first time, the possibility of application of the ejector nozzle under high-pressure cold spray conditions was investigated. A comparative analysis of the main characteristics of copper coatings deposited on aluminum alloy substrates using both the ejector and de Laval nozzles was also performed. It was demonstrated that the coatings obtained using the ejector nozzle are characterized by lower thickness, higher porosity, and similar microhardness as compared to the coatings obtained using de Laval nozzle. This development can be in demand in cases where the use of an open-type powder feeder is necessary to ensure technological simplicity of the cold spraying process.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings are not shared.

Materials availability

The raw/processed data required to reproduce these findings are not shared.

Code availability

Not applicable.

References

Koivuluoto H, Honkanen M, Vuoristo P (2010) Cold-sprayed copper and tantalum coatings − detailed FESEM and TEM analysis. Surf Coat Technol 204:2353–2361. https://doi.org/10.1016/j.surfcoat.2010.01.001

Vo P, Irissou E, Legoux J-G, Yue S (2013) Mechanical and microstructural characterization of cold-sprayed Ti-6Al-4V after heat treatment. J Therm Spray Tech 22:954–964. https://doi.org/10.1007/s11666-013-9945-4

Yin S, Jenkins R, Yan X, Lupoi R (2018) Microstructure and mechanical anisotropy of additively manufactured cold spray copper deposits. Mater Sci Eng A 734:67–76. https://doi.org/10.1016/j.msea.2018.07.096

Wu H, Xie X, Liu M, Verdy C, Zhang Y, Liao H, Deng S (2020) Stable layer-building strategy to enhance cold-spray-based additive manufacturing. Add Manuf 35

Klinkov SV, Kosarev VF, Zaikovskii VN (2011) Influence of flow swirling and exit shape of barrel nozzle on cold spraying. J Therm Spray Tech 20:837–844. https://doi.org/10.1007/s11666-011-9621-5

Zaikovskii VN, Klinkov SV, Kosarev VF, Melamed BM, Trubacheev GV (2014) Control of spray spot in cold spray technology. Part 1. Gas dynamic aspects. Thermophys Aeromech 21:105–112. https://doi.org/10.1134/S0869864314010107

Zaikovskii VN, Klinkov SV, Kosarev VF, Melamed BM, Trubacheev GV (2014) Control of spray spot shape in cold spray technology. Part 2. Spraying process. Thermophys Aeromech 21:223–230. https://doi.org/10.1134/S0869864314020085

Klinkov SV, Kosarev VF, Zaikovskii VN (2016) Preliminary study of cold spraying using radial supersonic nozzle. Surf Eng 32:701–706. https://doi.org/10.1179/1743294415Y.0000000070

Kiselev SP, Kiselev VP, Klinkov SV, Kosarev VF, Zaikovskii VN (2017) Study of the gas-particle radial supersonic jet in the cold spraying. Surf Coat Technol 313:24–30. https://doi.org/10.1016/j.surfcoat.2017.01.046

Sova A, Okunkova A, Grigoriev S, Smurov I (2013) Velocity of the particles accelerated by a cold spray micronozzle: experimental measurements and numerical simulation. J Therm Spray Tech 22:75–80. https://doi.org/10.1007/s11666-012-9846-y

Sova A, Smurov I, Doubenskaia M, Petrovskiy P (2018) Deposition of aluminum powder by cold spray micronozzle. Int J Adv Manuf Technol 95:3745–3752. https://doi.org/10.1007/s00170-017-1443-2

Song W, Jung K, Chun D-M, Ahn S-H, Lee CS (2010) Deposition of Al2O3 powders using nano-particle deposition system. Surf Rev Lett 17:189–193. https://doi.org/10.1142/S0218625X10013710

Cao F, Park H, Heo J, Kwon J, Lee C (2013) Effect of process gas flow on the coating microstructure and mechanical properties of vacuum kinetic-sprayed TiN layers. J Therm Spray Tech 22:1109–1119. https://doi.org/10.1007/s11666-013-9963-2

Alkhimov AP, Nesterovich NI, Papyrin AN, Kosarev VF, Shushpanov MM (1991) Device for coating deposition. Patent RF №1618777. https://new.fips.ru/iiss/document.xhtml?faces-redirect=true&id=45dc0f88cae0f7fba541b9aa6b070bab

Buzdygar TV, Kashirin AI, Kluev OF, Portnyagin YuI (1995) Method for obtaining coatings. Patent RF №2038411. https://new.fips.ru/iiss/document.xhtml?faces-redirect=true&id=56dd6ba44db8a2460afe7d9867fe49f9

Kroemmer W, Heinrich P, Richter P (2003) Cold spraying – equipment and application trends. In: Proc. ITSC, Orlando, Florida, USA, 5–8 May 2003, 97–102. https://doi.org/10.31399/asm.cp.itsc2003p0097

Klinkov SV, Kosarev VF, Sova AA (2006) Investigation of an ejector scheme for forming heterogeneous supersonic flows under cold gas-dynamic spraying conditions. Thermophys Aeromech 13:359–368. https://doi.org/10.1134/S086986430603005X

Shikalov VS, Klinkov SV, Kosarev VF (2016) Cold spraying on materials with low erosion resistance. AIP Conf Proc 1770:040015. https://doi.org/10.1063/1.4964084

Shikalov VS, Klinkov SV, Ryashin NS, Kosarev VF (2017) Measurement of bronze particles velocity in flow from the cold spraying ejector nozzle. Sib J Phys 12:51–54. https://doi.org/10.25205/2541-9447-2017-12-4-51-54

Adachi S, Ueda N (2017) Effect of cold-spray conditions using a nitrogen propellant gas on AISI 316L stainless steel-coating microstructures. Coatings 7:87. https://doi.org/10.3390/coatings7070087

Huang J, Ma W, Xie Y, Fukanum H, Zhang K, Wang G, Huang R (2019) Influence of cold gas spray processing conditions on the properties of 316L stainless steel coatings. Surf Eng 35:784–791. https://doi.org/10.1080/02670844.2019.1584967

Zahiri SH, Fraser D, Gulizia S, Jahedi M (2006) Effect of processing conditions on porosity formation in cold gas dynamic spraying of copper. J Therm Spray Tech 15:422–430. https://doi.org/10.1361/105996306X124437

Sudharshan Phani P, Srinivasa Rao D, Joshi SV, Sundararajan G (2007) Effect of process parameters and heat treatments on properties of cold sprayed copper coatings. J Therm Spray Tech 16:425–434. https://doi.org/10.1007/s11666-007-9048-1

Murray JW, Zuccoli MV, Hussain T (2018) Heat treatment of cold-sprayed C355 Al for repair: microstructure and mechanical properties. J Therm Spray Tech 27:159–168. https://doi.org/10.1007/s11666-017-0665-z

Chen C, Xie Y, Yan X, Yin S, Fukanuma H, Huang R, Zhao R, Wang J, Ren Z, Liu M, Liao H (2019) Effect of hot isostatic pressing (HIP) on microstructure and mechanical properties of Ti6Al4V alloy fabricated by cold spray additive manufacturing. Add Manuf 27:595–605. https://doi.org/10.1016/j.addma.2019.03.028

Petrovskiy P, Sova A, Doubenskaia M, Smurov I (2019) Influence of hot isostatic pressing on structure and properties of titanium cold-spray deposits. Int J Adv Manuf Technol 102:819–827. https://doi.org/10.1007/s00170-018-03233-5

Ito K, Ogawa K (2014) Effects of spark-plasma sintering treatment on cold-sprayed copper coatings. J Therm Spray Tech 23:104–113. https://doi.org/10.1007/s11666-013-0047-0

Vidyuk TM, Dudina DV, Korchagin MA, Gavrilov AI, Bokhonov BB, Ukhina AV, Esikov MA, Shikalov VS, Kosarev VF (2022) Spark plasma sintering treatment of cold sprayed materials for synthesis and structural modification: a case study using TiC-Cu composites. Mater Lett X 14:100140. https://doi.org/10.1016/j.mlblux.2022.100140

Funding

The research was carried out within the state assignment of the Ministry of Science and Higher Education of the Russian Federation using the facilities of the Equipment Sharing Center “Mechanics” of ITAM SB RAS. The authors thank R.E. Khakimov for his contribution to obtaining some experimental data.

Author information

Authors and Affiliations

Contributions

Conceptualization: Sergei V. Klinkov and Vladislav S. Shikalov; experiments: Vladislav S. Shikalov and Tomila M. Vidyuk; analysis of research results: Sergei V. Klinkov and Vladislav S. Shikalov; writing—original draft preparation: Sergei V. Klinkov and Vladislav S. Shikalov; writing—review and editing: Sergei V. Klinkov, Vladimir F. Kosarev, and Vladislav S. Shikalov. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The authors declare compliance with ethical standards.

Consent to participate

Not applicable.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Klinkov, S., Kosarev, V., Shikalov, V. et al. Development of ejector nozzle for high-pressure cold spray application: a case study on copper coatings. Int J Adv Manuf Technol 125, 4321–4328 (2023). https://doi.org/10.1007/s00170-023-11047-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11047-3