Abstract

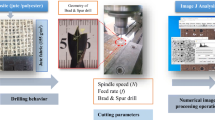

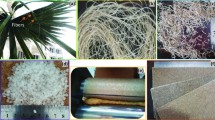

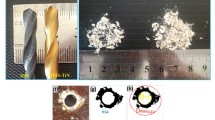

This current research is a continuation of previous publication by authors on the study of the delamination factor (Fd) of jute/polyester biocomposites based on the response surface methodology (RSM). However, in this study (part II), ANN statistical data analysis on the drilling capacity of a biocomposite according to the drilling parameters mainly by changing the length of the fibers is reported. The interaction of machining factors is studied using 3D surface plots, whereas optimal parameters of the process are predicted with the desirability/RSM and ANN/ genetic algorithm (GA) curve. ANN is used to obtain the best-trained fitness model for (GA) of the biocomposite material reinforced with jute fibers. RSM and ANN models showed good agreement with experimentally obtained results. However, ANN models were found to be more accurate than the RSM due to the higher correlation of ANN coefficients than RSM coefficients during training, validation, and testing.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Dembri I, Belaadi A, Boumaaza M, Bourchak M (2022) Tensile behavior and statistical analysis of Washingtonia filifera fibers as potential reinforcement for industrial polymer biocomposites. J Nat Fibers 19(16):14839–14854. https://doi.org/10.1080/15440478.2022.2069189

Dembri I, Belaadi A, Boumaaza M et al (2022) Drilling performance of short Washingtonia filifera fiber–reinforced epoxy biocomposites: RSM modeling. Int J Adv Manuf Technol 121:7833–7850. https://doi.org/10.1007/s00170-022-09849-y

Dutta S, Kim NK, Das R, Bhattacharyya D (2019) Effects of sample orientation on the fire reaction properties of natural fibre composites. Compos Part B, Eng 157:195–206

Lekrine A, Belaadi A, Makhlouf A et al (2022) Structural, thermal, mechanical and physical properties of Washingtonia filifera fibres reinforced thermoplastic biocomposites. Mater Today Commun 13:103574. https://doi.org/10.1016/j.mtcomm.2022.103574

Rezghi Maleki H, Hamedi M, Kubouchi M, Arao Y (2019) Experimental investigation on drilling of natural flax fiber-reinforced composites. Mater Manuf Process 34:283–292. https://doi.org/10.1080/10426914.2018.1532584

Zhou Y, Fan M, Chen L (2016) Interface and bonding mechanisms of plant fibre composites: an overview. Compos Part B, Eng 101:31–45

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Boumaaza M, Belaadi A, Bourchak M (2022) Systematic review on reinforcing mortars with natural fibers: challenges of environment-friendly option. J Nat Fibers 0:1–25. https://doi.org/10.1080/15440478.2022.2060408

Rangappa SM, Siengchin S, Parameswaranpillai J et al (2022) Lignocellulosic fiber reinforced composites: Progress, performance, properties, applications, and future perspectives. polym Compos 43:645–691. https://doi.org/10.1002/pc.26413

Mahdi E, Hernández Ochoa DR, Vaziri A et al (2020) Khalasa date palm leaf fiber as a potential reinforcement for polymeric composite materials. Compos Struct 265:113501. https://doi.org/10.1016/j.compstruct.2020.113501

Cherief M, Belaadi A, Bouakba M et al (2020) Behaviour of lignocellulosic fibre-reinforced cellular core under low-velocity impact loading: Taguchi method. Int J Adv Manuf Technol 108:223–233. https://doi.org/10.1007/s00170-020-05393-9

Makhlouf A, Belaadi A, Amroune S et al (2020) Elaboration and characterization of flax fiber reinforced high density polyethylene biocomposite: effect of the heating rate on thermo-mechanical properties. J Nat Fibers 19(10):3928–3941. https://doi.org/10.1080/15440478.2020.1848737

Cherief M, Belaadi A, Boumaaza M, Bourchak M (2021) The effect of geometry on the flexural properties of cellular structures reinforced with natural fibres: statistical approach. J Nat Fibers 19(14):8448–8462. https://doi.org/10.1080/15440478.2021.1964134

Benzannache N, Belaadi A, Boumaaza M, Bourchak M (2021) Improving the mechanical performance of biocomposite plaster/ Washingtonian filifira fibres using the RSM method. J Build Eng 33:101840. https://doi.org/10.1016/j.jobe.2020.101840

Belaadi A, Boumaaza M, Alshahrani H et al (2022) Drilling performance prediction of HDPE/Washingtonia fiber biocomposite using RSM, ANN, and GA optimization. Int J Adv Manuf Technol 123:1543–1564. https://doi.org/10.1007/s00170-022-10248-6

Belaadi A, Amroune S, Seki Y et al (2022) Extraction and characterization of a new lignocellulosic fiber from Yucca treculeana L. Leaf as potential reinforcement for industrial biocomposites. J Nat Fibers 15(19):12235–12250. https://doi.org/10.1080/15440478.2022.2054895

Belaadi A, Boumaaza M, Alshahrani H, Bourchak M (2022) Mechanical properties of natural cellulosic Yucca treculeana L. fiber for biocomposites applications: statistical analysis. J Nat Fibers 17(19):15501–15518. https://doi.org/10.1080/15440478.2022.2128505

Malik K, Ahmad F, Gunister E (2021) Drilling performance of natural fiber reinforced polymer composites: a review. J Nat Fibers 12(19):4761–4779. https://doi.org/10.1080/15440478.2020.1870624

Abilash N, Sivapragash M (2016) Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J King Saud Univ - Eng Sci 28:92–102. https://doi.org/10.1016/j.jksues.2013.09.004

Díaz-Álvarez A, Díaz-Álvarez J, Santiuste C, Miguélez MH (2019) Experimental and numerical analysis of the influence of drill point angle when drilling biocomposites. Compos Struct 209:700–709. https://doi.org/10.1016/j.compstruct.2018.11.018

Nassar MMA, Arunachalam R, Alzebdeh KI (2017) Machinability of natural fiber reinforced composites: a review. Int J Adv Manuf Technol 88:2985–3004. https://doi.org/10.1007/s00170-016-9010-9

Bajpai PK, Debnath K, Singh I (2015) Hole making in natural polylactic acid laminates : an experimental investigation. J Thermoplast Compos Mater 30:1–17. https://doi.org/10.1177/0892705715575094

Tabet Z, Belaadi A, Boumaaza M, Bourchak M (2021) Drilling of a bidirectional jute fibre and cork-reinforced polymer biosandwich structure: ANN and RSM approaches for modelling and optimization. Int J Adv Manuf Technol 117:3819–3839. https://doi.org/10.21203/rs.3.rs-503708/v1

Adda B, Belaadi A, Boumaaza M, Bourchak M (2021) Experimental investigation and optimization of delamination factors in the drilling of jute fiber–reinforced polymer biocomposites with multiple estimators. Int J Adv Manuf Technol 116:2885–2907. https://doi.org/10.1007/s00170-021-07628-9

Belaadi A, Laouici H, Bourchak M (2020) Mechanical and drilling performance of short jute fibre-reinforced polymer biocomposites: statistical approach. Int J Adv Manuf Technol 106:1989–2006. https://doi.org/10.1007/s00170-019-04761-4

Debnath K, Singh I, Dvivedi A (2014) Drilling characteristics of sisal fiber-reinforced epoxy and polypropylene composites. Mater Manuf Process 29:1401–1409. https://doi.org/10.1080/10426914.2014.941870

Mercy JL, Sivashankari P, Sangeetha M et al (2020) Genetic optimization of machining parameters affecting thrust force during drilling of pineapple fiber composite plates – an experimental approach. J Nat Fibers 12(19):1729–1740. https://doi.org/10.1080/15440478.2020.1788484

Belaadi A, Boumaaza M, Alshahrani H, Bourchak M (2022) Delamination in drilling of jute/cork-reinforced polymer biosandwich materials: optimization by response surface methodology and genetic algorithm. Int J Adv Manuf Technol 122:2095–2111. https://doi.org/10.1007/s00170-022-10001-z

Salih A, Rafiq S, Sihag P et al (2021) Systematic multiscale models to predict the effect of high-volume fly ash on the maximum compression stress of cement-based mortar at various water/cement ratios and curing times. Measurement 171:108819. https://doi.org/10.1016/j.measurement.2020.108819

Mohammed A, Rafiq S, Sihag P et al (2020) ANN, M5P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash. J Mater Res Technol 9:12416–12427. https://doi.org/10.1016/j.jmrt.2020.08.083

Deng F, He Y, Zhou S et al (2018) Compressive strength prediction of recycled concrete based on deep learning. Constr Build Mater 175:562–569. https://doi.org/10.1016/j.conbuildmat.2018.04.169

Topçu İB, Sarıdemir M (2008) Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Comput Mater Sci 41(3):305–311. https://doi.org/10.1016/j.commatsci.2007.04.009

Saaidia A, Belaadi A, Haddad A (2022) Moisture absorption of cork-based biosandwich material extracted from Quercussuber L. plant: ANN and Fick’s modelling. J Nat Fibers 16(19):12486–12503. https://doi.org/10.1080/15440478.2022.2072996

Kewalramani MA, Gupta R (2006) Concrete compressive strength prediction using ultrasonic pulse velocity through artificial neural networks. Autom Constr 15:374–379. https://doi.org/10.1016/j.autcon.2005.07.003

Yilmaz I, Yuksek G (2009) Prediction of the strength and elasticity modulus of gypsum using multiple regression, ANN, and ANFIS models. Int J Rock Mech Min Sci 46:803–810. https://doi.org/10.1016/j.ijrmms.2008.09.002

Demir F (2008) Prediction of elastic modulus of normal and high strength concrete by artificial neural networks. Constr Build Mater 22:1428–1435. https://doi.org/10.1016/j.conbuildmat.2007.04.004

Mansour MY, Dicleli M, Lee JY, Zhang J (2004) Predicting the shear strength of reinforced concrete beams using artificial neural networks. Eng Struct 26:781–799. https://doi.org/10.1016/j.engstruct.2004.01.011

Boumaaza M, Belaadi A, Bourchak M (2021) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: part II optimization comparison between ANN and RSM statistics. J Nat Fibers 14(19):8367–8382. https://doi.org/10.1080/15440478.2021.1964129

Boumaaza M, Belaadi A, Bourchak M et al (2022) Comparative study of flexural properties prediction of Washingtonia filifera rachis biochar bio-mortar by ANN and RSM models. Constr Build Mater 318:125985. https://doi.org/10.1016/j.conbuildmat.2021.125985

Belaadi A, Boumaaza M, Amroune S, Bourchak M (2020) Mechanical characterization and optimization of delamination factor in drilling bidirectional jute fibre-reinforced polymer biocomposites. Int J Adv Manuf Technol 111:2073–2094. https://doi.org/10.1007/s00170-020-06217-6

Sridharan V, Muthukrishnan N (2013) Optimization of machinability of polyester/modified jute fabric composite using grey relational analysis (GRA). Procedia Eng 64:1003–1012. https://doi.org/10.1016/j.proeng.2013.09.177

Pailoor S, Murthy HNN, Sreenivasa TN (2021) Drilling of in-line compression molded jute / polypropylene composites. J Nat Fibers 18:91–104. https://doi.org/10.1080/15440478.2019.1612309

Singh H, Dewangan B, Jain PK (2021) Experimental study on drilling characteristics of the hybrid sisal–jute fibre epoxy composites. J Micromanufacturing 4:157–168. https://doi.org/10.1177/25165984211015413

Mustafa Z, Idrus NH, MohdHadzley AB et al (2020) Optimization of drilling process parameters on delamination factor of Jute reinforced unsaturated polyester composite using Box-Behnken design of experiment. J Mech Eng Sci 14:6295–6303. https://doi.org/10.15282/jmes.14.1.2020.08.0493

Margabandu S, Subramaniam S (2020) An experimental investigation of thrust force, delamination and surface roughness in drilling of jute/carbon hybrid composites. World J Eng 17:661–674. https://doi.org/10.1108/WJE-03-2020-0080

S Sathish Kumar, Suresh AV, Nagamadhu M et al (2019) Optimization of drilling parameters on alkaline treated jute fiber sandwich material 3(8):2454–2459. https://doi.org/10.35940/ijrte.C4693.098319

Vinayagamoorthy R (2017) Parametric optimization studies on drilling of sandwich composites using the Box-Behnken design. Mater Manuf Process 32:645–653. https://doi.org/10.1080/10426914.2016.1232811

Ravikumar P, Rajeshkumar G, Manimegalai P et al (2022) Delamination and surface roughness analysis of jute/polyester composites using response surface methodology: consequence of sodium bicarbonate treatment. J Ind Text 51:360S-377S. https://doi.org/10.1177/15280837221077040

Ramnath BV, Sharavanan S, Jeykrishnan J (2017) Optimization of process parameters in drilling of fibre hybrid composite using Taguchi and grey relational analysis. In: IOP ConfSer: Mater Sci Eng 183:12003. https://doi.org/10.1088/1757-899X/183/1/012003

Sridharan V, Raja T, Muthukrishnan N (2016) Study of the effect of matrix, fibre treatment and graphene on delamination by drilling jute / epoxy nanohybrid composite. Arab J Sci Eng (41):1883–1894. https://doi.org/10.1007/s13369-015-2005-2

Aravindh S, Umanath K (2015) Delamination in drilling of natural fibre reinforced polymer composites produced by compression moulding. Appl Mech Mater 767:796–800. https://doi.org/10.4028/www.scientific.net/AMM.766-767.796

Rezghi Maleki H, Hamedi M, Kubouchi M, Arao Y (2019) Experimental study on drilling of jute fiber reinforced polymer composites. J Compos Mater 53:283–295

Vinayagamoorthy R, Rajeswari N, Sivanarasimha S, Balasubramanian K (2015) Fuzzy based optimization of thrust force and torque during drilling of natural hybrid composites. In: Applied Mechanics and Materials. Trans Tech Publ 787:265–269. https://doi.org/10.4028/www.scientific.net/AMM.787.265

Belaadi A, Boumaaza M, Amroune S, Bourchak M (2020) Mechanical characterization and optimization of delamination factor in drilling bidirectional jute fibre-reinforced polymer biocomposites. Int J Adv Manuf Technol 111:2073–2094. https://doi.org/10.1007/s00170-020-06217-6

Yallew TB, Kumar P, Singh I (2015) A study about hole making in woven jute fabric-reinforced polymer composites. Proc IMechE Part L J Mater Des Appl 4(230):888–898. https://doi.org/10.1177/1464420715587750

Acknowledgements

This research work was funded by Institutional Fund Projects under grant no. (IFPIP:1304-135-1443). The authors gratefully acknowledge technical and financial support provided by the Ministry of Education and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Funding

This study has been funded by Institutional Fund Projects under grant no. (IFPIP:1304–135-1443).

Author information

Authors and Affiliations

Contributions

Ahmed Belaadi: Conceptualization, investigation, methodology, supervision, writing–review, and editing.

Messaouda Boumaaza: Conceptualization, investigation, writing–review, and editing.

Hassan Alshahrani: Investigation, writing–review, and editing.

Mostefa Bourchak: Investigation, writing–review, and editing.

Corresponding author

Ethics declarations

Ethics approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or contains no material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Conflict of interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belaadi, A., Boumaaza, M., Alshahrani, H. et al. Effect of jute fiber length on drilling performance of biocomposites: optimization comparison between RSM, ANN, and genetic algorithm. Int J Adv Manuf Technol 124, 3579–3599 (2023). https://doi.org/10.1007/s00170-022-10801-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10801-3