Abstract

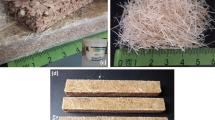

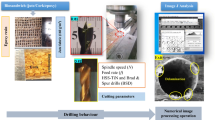

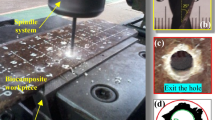

The best practice to obtain a high-quality hole drilling is to minimize the delamination factor during the drilling process. This can be assured by correctly selecting the appropriate process parameters. The most significant parameters affecting the performance response are feed rate (f), spindle speed (N) and drill diameter (d). The current study aims to identify appropriate tools for drilling the hybrid jute/cork biosandwich based on multi-objective response surface methodology (RSM) and genetic algorithm (GA). The work aims to optimize the drilling parameters for minimizing the delamination factor of two tools, one made from High Speed Steel (HSS) and the other made from High Speed Steel covered with Titanium Nitride (HSS-TiN). The results revealed that the HSS-TiN tool is the more suitable to achieve a minimum delamination of 1.165 compared to the HSS tool (1.214 and 1.249 obtained by RSM and GA, respectively), with 50 mm/min feed rate, 1800 rpm spindle speed and a 5-mm diameter.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Jia R, Wang Q, Feng P (2021) A comprehensive overview of fibre-reinforced gypsum-based composites (FRGCs) in the construction field. Compos Part B Eng 205:108540. https://doi.org/10.1016/j.compositesb.2020.108540

Friedrich D (2021) Thermoplastic moulding of Wood-Polymer Composites (WPC): a review on physical and mechanical behaviour under hot-pressing technique. Compos Struct 262:113649. https://doi.org/10.1016/j.compstruct.2021.113649

Thakur VK, Thakur MK (2014) Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr Polym 109:102–117. https://doi.org/10.1016/j.carbpol.2014.03.039

Tavares TD, Antunes JC, Ferreira F, Felgueiras HP (2020) Biofunctionalization of natural fiber-reinforced biocomposites for biomedical applications. Biomol 10

Lefeuvre A, Bourmaud A, Morvan C, Baley C (2014) Tensile properties of elementary fibres of flax and glass: analysis of reproducibility and scattering. Mater Lett 130:289–291. https://doi.org/10.1016/j.matlet.2014.05.115

Boumaaza M, Belaadi A, Bourchak M (2022) Systematic review on reinforcing mortars with natural fibers: challenges of environment-friendly option. J Nat Fibers 1–25. https://doi.org/10.1080/15440478.2022.2060408

Mokhothu TH, John MJ (2015) Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr Polym 131:337–354. https://doi.org/10.1016/j.carbpol.2015.06.027

Savic A, Antonijevic D, Jelic I, Zakic D (2020) Thermomechanical behavior of bio-fiber composite thermal insulation panels. Energy Build 229:110511. https://doi.org/10.1016/j.enbuild.2020.110511

Malik K, Ahmad F, Gunister E (2021) Drilling performance of natural fiber reinforced polymer composites: a review. J Nat Fibers 1–19. https://doi.org/10.1080/15440478.2020.1870624

Dembri I, Belaadi A, Boumaaza M et al (2022) Drilling performance of short Washingtonia filifera fiber–reinforced epoxy biocomposites: RSM modeling. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-022-09849-y

Abd-Elwahed MS (2022) Drilling process of GFRP composites: modeling and optimization using hybrid ANN. Sustain 14

Chandramohan D, Marimuthu K (2011) Drilling of natural fiber particle reinforced polymer composite material. Int J Adv Eng Res Stud I:134–145

Athijayamani A, Thiruchitrambalam M, Natarajan U, Pazhanivel B (2010) Influence of alkali-treated fibers on the mechanical properties and machinability of roselle and sisal fiber hybrid polyester composite. Polym Compos 31:723–731. https://doi.org/10.1002/pc.20853

Mylsamy K, Rajendran I (2011) Influence of alkali treatment and fibre length on mechanical properties of short Agave fibre reinforced epoxy composites. Mater Des 32:4629–4640. https://doi.org/10.1016/j.matdes.2011.04.029

Dilli Babu G, Sivaji Babu K, Uma Maheswar Gowd B (2013) Optimization of machining parameters in drilling hemp fiber reinforced composites to maximize the tensile strength using design experiments. Indian J Eng Mater Sci

Jayabal S, Velumani S, Navaneethakrishnan P, Palanikumar K (2013) Mechanical and machinability behaviors of woven coir fiber-reinforced polyester composite. Fibers Polym. https://doi.org/10.1007/s12221-013-1505-5

Venkateshwaran N, ElayaPerumal A (2013) Hole quality evaluation of natural fiber composite using image analysis technique. J Reinf Plast Compos 32:1188–1197. https://doi.org/10.1177/0731684413486847

Debnath K, Singh I, Dvivedi A (2014) Drilling characteristics of sisal fiber-reinforced epoxy and polypropylene composites. Mater Manuf Process 29:1401–1409. https://doi.org/10.1080/10426914.2014.941870

Patel K, Chaudhary V, Gohil PP, Patel K (2015) Investigation on drilling of banana fibre reinforced composites BT–Proceedings of the 2nd International Conference on Civil, Materials and Environmental Sciences. Atlantis Press, pp 201–205

Jayabal S, Natarajan U (2010) Optimization of thrust force, torque, and tool wear in drilling of coir fiber-reinforced composites using Nelder-Mead and genetic algorithm methods. Int J Adv Manuf Technol 51:371–381. https://doi.org/10.1007/s00170-010-2605-7

Jayabal S, Natarajan U (2011) Drilling analysis of coir – fibre-reinforced polyester composites. Bull Mater Sci 34:1563–1567. https://doi.org/10.1007/s12034-011-0359-y

Tabet Z, Belaadi A, Boumaaza M, Bourchak M (2021) Drilling of a bidirectional jute fibre and cork-reinforced polymer biosandwich structure: ANN and RSM approaches for modelling and optimization. Int J Adv Manuf Technol 117:3819–3839. https://doi.org/10.21203/rs.3.rs-503708/v1

Adda B, Belaadi A, Boumaaza M, Bourchak M (2021) Experimental investigation and optimization of delamination factors in the drilling of jute fiber–reinforced polymer biocomposites with multiple estimators. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-07628-9

Belaadi A, Laouici H, Bourchak M (2020) Mechanical and drilling performance of short jute fibre-reinforced polymer biocomposites: statistical approach. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-04761-4

Belaadi A, Boumaaza M, Amroune S, Bourchak M (2020) Mechanical characterization and optimization of delamination factor in drilling bidirectional jute fibre-reinforced polymer biocomposites. Int J Adv Manuf Technol 111:2073–2094. https://doi.org/10.1007/s00170-020-06217-6

Cherief M, Belaadi A, Bouakba M et al (2020) Behaviour of lignocellulosic fibre-reinforced cellular core under low-velocity impact loading: Taguchi method. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-05393-9

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. JOM 58

Saaidia A, Belaadi A, Haddad A (2022) Moisture absorption of cork-based biosandwich material extracted from Quercussuber L. Plant: ANN and Fick’s modelling. J Nat Fibers 1–18. https://doi.org/10.1080/15440478.2022.2072996

Davim JP, Rubio JC, Abrao AM (2007) A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos Sci Technol 67:1939–1945. https://doi.org/10.1016/j.compscitech.2006.10.009

Sridharan V, Muthukrishnan N (2013) Optimization of machinability of polyester/modified jute fabric composite using grey relational analysis (GRA). Procedia Eng

Sridharan V, Raja T, Muthukrishnan N (2016) Study of the effect of matrix, fibre treatment and graphene on delamination by drilling jute/epoxy nanohybrid composite. Arab J Sci Eng 10–14. https://doi.org/10.1007/s13369-015-2005-2

Kumar K, Verma RK (2022) Measurement and evaluation of delamination factors and thrust force generation during drilling of multiwall carbon nanotube (MWCNT) modified polymer laminates. Arch Mech Eng 0–2. https://doi.org/10.24425/ame.2022.140417

Ramaswamy A, Perumal AV (2020) Multi-objective optimization of drilling EDM process parameters of LM13 Al alloy–10ZrB2–5TiC hybrid composite using RSM. J Braz Soc Mech Sci Eng 42:432. https://doi.org/10.1007/s40430-020-02518-9

Boumaaza M, Belaadi A, Bourchak M (2021) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: optimization using RSM. J Nat Fibers 18:2220–2240. https://doi.org/10.1080/15440478.2020.1724236

Boumaaza M, Belaadi A, Bourchak M et al (2022) Comparative study of flexural properties prediction of Washingtonia filifera rachis biochar bio-mortar by ANN and RSM models. Constr Build Mater 318:125985. https://doi.org/10.1016/j.conbuildmat.2021.125985

Belaadi A, Boumaaza M, Amroune S, Bourchak M (2020) Mechanical characterization and optimization of delamination factor in drilling bidirectional jute fibre-reinforced polymer biocomposites. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-06217-6

Boumaaza M, Belaadi A, Bourchak M (2021) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: Part II Optimization comparison between ANN and RSM statistics. J Nat Fibers 1–16. https://doi.org/10.1080/15440478.2021.1964129

Benzannache N, Belaadi A, Boumaaza M, Bourchak M (2021) Improving the mechanical performance of biocomposite plaster/Washingtonian filifira fibres using the RSM method. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101840

Vijayan D, Rajmohan T (2019) Modeling and evolutionary computation on drilling of carbon fiber-reinforced polymer nanocomposite: an integrated approach using RSM based PSO. J Braz Soc Mech Sci Eng 41:395. https://doi.org/10.1007/s40430-019-1892-7

Qiu X, Li P, Li C et al (2018) Study on chisel edge drilling behavior and step drill structure on delamination in drilling CFRP. Compos Struct 203:404–413. https://doi.org/10.1016/j.compstruct.2018.07.007

Abilash N, Sivapragash M (2016) Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J King Saud Univ - Eng Sci 28:92–102. https://doi.org/10.1016/j.jksues.2013.09.004

Ramya Devi G, Palanikumar K (2019) Analysis on drilling of woven glass fibre reinforced aluminium sandwich laminates. J Mater Res Technol 8:1024–1035. https://doi.org/10.1016/j.jmrt.2018.06.021

Babu GD, Babu KS, Gowd BUM (2013) Effect of machining parameters on milled natural fiber-reinforced plastic composites. J Adv Mech Eng 1(1):1–12. https://doi.org/10.7726/jame.2013.1001

Funding

The authors are thankful to the Deanship of Scientific Research at Najran University for funding this work under the Research Collaboration Funding program grant code (NU/RC/SERC/11/4).

Author information

Authors and Affiliations

Contributions

AB: conceptualization, investigation, methodology, supervision, writing–review and editing. MB: conceptualization, investigation, writing–review and editing. HA: investigation, writing–review and editing. MB: investigation, writing–review and editing.

Corresponding author

Ethics declarations

Ethics approval

The work contains no libellous or unlawful statements, does not infringe on the rights of others or contains no material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Short hybrid jute fibers/cork/epoxy biosandwich drilling carried out.

• HSS-TiN tool generated minimal delamination.

• Feed rate is identified as the most significant drilling parameter.

• Optimization of the jute/cork biosandwich according to a desirability function approach and GA.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belaadi, A., Boumaaza, M., Alshahrani, H. et al. Delamination in drilling of jute/cork-reinforced polymer biosandwich materials: optimization by response surface methodology and genetic algorithm. Int J Adv Manuf Technol 122, 2095–2111 (2022). https://doi.org/10.1007/s00170-022-10001-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10001-z