Abstract

The Abbé error is a key factor for high-precision CNC machine tools. Unluckily, it is not taken into account in traditional machine tool volumetric error models. In this respect, based on the traditional machine tool volumetric error models, a new machine tool volumetric error model containing Abbé error is performed by analyzing the mechanism of Abbé error formation tool volumetric and based on 21-item geometric error measurement data, Abbé arm, and angle functional relationship. Moreover, integrated qualitative and quantitative simulation method for evaluation of machine tool space precision are correspondingly presented. Finally, an example was utilized to further verify the value of our model by means of analysis and comparison of the tooling precision prior to and after performance of compensation, and its validity and feasibility were proved. This study provides an important modeling method for high-precision machine tools and has very important theoretical significance and practical value.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With continuous development of science and technology, high machining precision mechanical products are more required [1, 2]. As equipment has becoming more popular in the manufacturing industry, CNC machine tools are facing new challenges and opportunities currently.

Measurement of tooling errors dominates improvement of the tooling precision and determines effects of error compensation. There are many classic methods for measuring tooling errors, such as a laser tracker [3,4,5], laser displacement sensor [6], touch-trigger probe [7, 8], non-contact optical components [9], R-test device [10], and ball plate [11, 12]. Among the many volumetric error modeling methods, the homogeneous-coordinate transformation matrix (HTM) method based on the multi-body system theory [13,14,15] is becoming popular in 3- and 5-axis machine tools and the derivation of the volumetric error compensation models for multi-axis machining or measuring equipment such as coordinate measuring machines [16] due to its advantages of simple understanding and wide application range. Kim established a volumetric error compensation model for 3-D measuring machines and 3-axis machine tools based on the theory of rigid body kinematics [17]. Chen et al. attempted to establish a total of 12 polynomial error models for the 3-axis linkage of machine tools based on the error measurements of the entire working volume. They initially discussed the error prediction methods of machine tools at various volume positions [18]. Zuo and Li proposed a method to change the trajectory of the cue working space and carried out volumetric error modeling in turn, which can be applied to accurately solve the rotation error elements of the tool and workbench coordinate systems [19]. Zhang et al. established error-free motion equations between adjacent bodies by employing the multi-body theory. He established the topological structure relationship of various moving parts and the low-order body array and completed the error modeling of machine tool grinding system in accordance with the adjacent body kinematics theory to predict the machining precision [20]. The current measurement and modeling methods for tooling errors greatly promoted improvement of tooling error compensation techniques. Unluckily, the positional relationship between the measurement and actual processing points was not taken into account in previous findings. While the center line of the motion axis is inconsistent with the moving direction of the working point of the measuring system, the Abbé deviation will occur [21,22,23,24]. The errors primarily come from the fact that the deflection errors can be amplified by the Abbé deviation. Namely, the Abbé error due to the Abbé deviation will seriously restrict improvement of compensation effects of the CNC tools.

Based on analysis of the Abbé principle, a machine tool volumetric error model where the Abbé error has been taken into account was put forward here. Based on comparison of the errors solved by the traditional measurement methods coupled with consideration of the Abbé error, an effect of the Abbé error on the linear error is analyzed, and an error compensation module is specially developed. Finally, an example is utilized to verify compensation effects of the traditional error model and our volumetric error model where the Abbé error was considered. The analysis and comparison are performed by means of quantitative and qualitative evaluation of diagonal line Matlab simulations.

2 Modeling method

As for a traditional modeling method, the HTM is becoming more popular in the volumetric error modeling of machine tools. While a comprehensive mathematical model of tooling errors is derived by means of the HTM, the Cartesian coordinate system is necessarily established on the tool, worktable, spindle, and workpiece. Subsequently, the dynamic characteristics of the various movement pair errors and the chain conversion among each movement pair are described according to the principle of HTM. The coordinate conversion matrix between each coordinate system is established. Finally, the relationship between the tool and workpiece coordinate systems is established according to the relative positions of the tool tip, and the cutting point at the same point in space. Equations are solved to obtain the comprehensive mathematical model containing various errors. The traditional error model is as follows [25,26,27]:

where \(\Delta x\), \(\Delta y\), and \(\Delta z\) represent the position error of the actual cutting point relative to the ideal cutting point; \({\delta }_{xm}(x)\),\({\delta }_{ym}(x)\), and \({\delta }_{zm}(x)\) are the moving errors in direction X; \({\varepsilon }_{xm}(x)\), \({\varepsilon }_{ym}(x)\), and \({\varepsilon }_{zm}(x)\) are the corresponding angle errors while the work bench moves along axis X—in directions X, Y, and Z, respectively, and \({\alpha }_{xy}\),\({\alpha }_{xz}\), and \({\alpha }_{yz}\) represent the relative verticality errors between axes X, Y, and Z.

3 Optimization of our comprehensive error model based on Abbé principle

The tooling error model is necessary to accurately compensate errors. The laser interferometer-based measurements of the tooling errors are movement errors of the laser head on the worktable, rather than tool tip point errors. Also, there is a certain difference between them due to the Abbé error here. Thus, it is more reasonable to consider the comprehensive error modeling by means of a traditional error model where the Abbé error has been taken into account.

3.1 Measurement error conversion

Traditional error model modeling is derived from the kinematics of the mechanism. While the traditional error model error compensation model is utilized to compensate comprehensive errors on the machine tool, it is necessary to guarantee that the cutting point shall coincide with the coordinate origin of the workpiece and tool coordinate systems. While the laser interferometer is utilized to measure the geometric errors of the machine tool, the position of the tool cutting point does not coincide with its corresponding error measuring point in space. The offset between both the points is shown in Fig. 1.

As for the machine tool where a grating ruler acts as the position control unit, the position of its motion axis is obtained by real-time feedback of its grating ruler. In process, its cutting point and grating ruler are not coaxial. There is an Abbé offset in space and an angular error in process. Thus, Abbé errors occur at its cutting point. The true position errors of the cutting point are composed of the positioning and angle errors at the grating ruler and the Abbé error due to the Abbé deviation.

While the offset between the cutting point and the X-axis grating ruler in direction Z is assumed as \({L}_{z}(x)\), the X-axis pitch angle error is \({\varepsilon }_{ym}(x)\), so the corresponding Abbé error in direction X due to the X-axis pitch angle error at the cutting point is \({\varepsilon }_{ym}(x)\times {L}_{z}(x)\) which (Fig. 2).

Actually, the cutting point and the reading head of the grating scale are offset in 3 directions. As shown in Fig. 3, the yaw angle error of the motion axis may also introduce the Abbé error at its cutting point. Therefore, the geometric errors in direction X due to axis X at its cutting point should be composed of 3 parts:

-

1.

The reference positioning error at the grating ruler;

-

2.

The Abbé error due to the pitch angle error; and.

-

3.

The Abbé error due to the yaw angle error.

The calculation equation is as follows:

where \({\delta_{x\alpha }}\) represents the reference positioning error at the X-axis grating scale reading head, \({\delta_{xm}}(x)\) represents the measured positioning error while the measuring axis is axis X, and \({L_z}(x)\) and \({L_y}(x)\) are the offsets in directions Z and Y between the X-axis grating scale reading head and the cutting point, respectively.

3.2 Error model optimization

Our analysis indicates that the reference positioning errors at the reading head of the grating ruler are all the same although the positioning errors of different measurement positions are different. The positioning errors measured by means of the above equation-based instrument are converted into the reference positioning errors at the reading head of the grating ruler. Then, they are substituted into the compensation model.

While the error model is derived based on the multi-system theory, 6 geometric errors of the motion axis must be located at the same position. Thus, conversion of the positioning errors should conform to the Bryan principle, by means of which the straightness errors are converted from the measuring point to the grating scale reading head. Since the motion axis can be regarded as a rigid body, the angle errors are not necessarily converted. Conversion of X-axis positioning and straightness errors shall conform to the following equations:

where \({\delta_{x\alpha }}\), \({\delta_{y\alpha }}\), and \({\delta_{z\alpha }}\) represent the error value of directions X, Y, and Z at the reading head of the grating ruler.

Similarly, the conversion equations of Y- and Z-axes positioning, and straightness errors can be obtained. The specific conversion process is shown in Fig. 4.

The optimized XYTZ type comprehensive error model is as follows:

4 Application verification

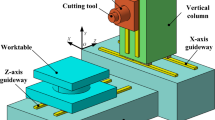

A 3-axis vertical machining center (Model: XHK714; manufacturer: Hubei Jiangshan Huake Digital Equipment Technology Co., Ltd.) is our research object, whose overall structure characteristic dimensions are as follows:

-

X-axis travel: 1800 mm;

-

Y-axis travel: 1500 mm; and.

-

Z-axis travel: 1200 mm.

5 Acquisition of tooling errors

In case of non-collision and consideration of the rationality of experiments, 3-axis travels are selected as follows:

-

X-axis: 0 ~ 1500;

-

Y-axis: −2550 ~ −1050; and.

-

Z-axis: −900 ~ 200.

In case that the national relevant measurement requirements are satisfied, the measurement spacings are selected as 150 mm, 150 mm, and 110 mm. Axes X, Y, and Z are all divided into 11 segments. Six geometric errors of axes X, Y, and Z are measured successively with the laser interferometer (Fig. 5). The measurements are shown in Fig. 6.

Figure 6a–c presents parameters of axes X, Y, and Z as follows:

-

Axis X.

-

Measuring travel: [0, −1500]mm.

-

Measuring distance: 150 mm.

-

Positioning error: −40.2 ~ −65.6 μm.

-

Straightness error: −14.4 ~ 11.9 μm.

-

Angle error: −7.1 ~ 9.7 μm.

-

Axis Y.

-

Measurement stroke: [−2550, −1050]mm.

-

Measurement interval: 150 mm.

-

Positioning error: −0.2 ~ −24.1 μm.

-

Straightness error: −18.5 ~ 22.5 μm.

-

Angle error: −41.4 ~ 2.7 μm.

-

Axis Z.

-

Measurement stroke: [−900, 200]mm.

-

Measurement interval: 110 mm.

-

Positioning error: 0.2 ~ 41.7 μm.

-

Straightness error: −77.2 ~ 68.8 μm.

-

Angle error: −5.7 ~ 68.9 μm.

6 Analysis of machine tool geometric error data considering Abbé error

Since the 21-item geometric errors are measured by means of the laser interferometer, the axis of the displacement sensor equipped in the laser interferometer is not in the extension line of the motion axis of the measuring head, resulting in an Abbé error. According to Eq. (3), the linear errors are shown in Fig. 7 in case that the Abbé error has been taken into account:

Positioning errors of axes X, Y, and Z are between −62.4 ~ 8.3 μm, −0.1 ~ 16.3 μm, and −63.8 ~ 1.4 μm, respectively. Their corresponding straightness errors are between −32.1 ~ 4.5 μm, −8.7 ~ 26.1 μm, and −30.8 ~ 44.2 μm, respectively. The maximum measured tooling geometric errors and those including the Abbé errors are shown in Table 1.

Comparative analysis of the measured tooling geometric errors and those calculations including the Abbé errors indicates that effects of the angle and Abbé errors, which result in the fact that there is often a difference of 5–20 μm between them. Also, because the tooling angle and Abbé errors result in the properties of positive and negative of errors easily change, application of a machine tool volumetric error optimization model that contains Abbé errors can bring about more accurate results.

6.1 Simulation evaluation

Based on linearly fitting of the error measurements by means of the laser interferometer, one 18-item geometric error model is obtained. The errors are substituted into Eq. (1). A comprehensive error model is derived based on the traditional error model. While simulation is performed by means of MATLAB, the tooling comprehensive error model is imported into the error calculation program for calculation, and the volumetric errors \((\Delta x, \Delta y, \Delta z)\) of the characteristic points in the volumetric error field is obtained. Error interval color separation is also performed by means of Matlab on the volumetric errors \((\Delta x, \Delta y, \Delta z)\), and color separation diagrams of the error field are shown in Fig. 8.

Figure 8a–c present the errors (Ex, Ey, and Ez) of axes X, Y, and Z in the whole space.

Ex:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−2550 ~ −1050)mm; and Z: (−130 ~ 200)mm): < 20 μm.

Volumetric errors (X: (−1350 ~ −1500)mm; Y: (−2550 ~ −1200)mm; and Z: (−900 ~ −790)mm): up to 80 μm.

Ey:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−2550 ~ −1050)mm; and Z: (−900 ~ 200)mm): < 10 μm; one volumetric error: 10 ~ 35 μm.

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−1650 ~ −1050)mm; and Z: (−900 ~ −680)mm): > 20 μm.

Ez:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−1350 ~ −1050)mm; and Z: (−900 ~ 200)mm): < 40 μm.

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−2550 ~ −1950)mm; and Z: (−900 ~ −200)mm): > 60 μm.

Based on measurements under consideration of the linearly fitted Abbé errors, the optimized functions are substituted into Eq. (4), and a 3-D comprehensive error model is obtained. Errors (Ex, Ey, Ez) of each space point are calculated by means of the optimized volumetric error model. The color separation charts are applied to indicate the error interval ranges.

Figure 9a–c present the errors (Ex, Ey, and Ez) of axes X, Y, and Z in the whole space.

Ex:

Volumetric errors (X: (−1350 ~ −1500)mm; Y: (−2550 ~ −1050)mm; and Z: (−130 ~ 200)mm): up to 90 μm.

Ey:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−1050 ~ −1500)mm; and Z: (−350 ~ 200)mm): > 20 μm.

Ez:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−1500 ~ −1050)mm; and Z: (−900 ~ 200)mm): > 60 μm.

Analysis of Figs. 8 and 9 indicates that the error peak about 80 μm, 35 μm, and 70 μm in directions X, Y, and Z in the volumetric error diagrams which are obtained by means of the traditional error model simulation. In contrast, their peaks are above 90 μm, 30 μm, and 80 μm in turn in the volumetric error maps based on simulations by means of the traditional error model and the Abbé error optimization. There is generally a difference of 5 ~ 15 μm in the same direction for the both models. Such fact shows that the Abbé error can greatly affect the tooling volumetric errors. The volumetric error clouds indicate that the volumetric errors based on simulations by means of the traditional error model optimized by the Abbé error are larger in most of the machine tool space.

6.2 Error compensation

6.2.1 Development of our compensation system software

After the compensation data are derived on the execution end of the machine tools, a volumetric error compensation module is developed on our Huazhong 8 CNC system platform based on the tooling volumetric error model and measured data characteristics. Such module contains basic X, Y, and Z-axes measurement intervals, grid spacings, and point settings and compensation file reading functions. Volumetric error compensation parameters can be set, which include the compensation ratio and switch. The interface of our compensation module is shown in Fig. 10.

6.2.2 Precision evaluation after performance of compensation

Simulation qualitative evaluation

After the tooling volumetric errors based on the traditional error model have been compensated by means of our software, the compensation effects are simulated and qualitatively evaluated. The tooling volumetric error field is shown in the Fig. 11.

Figure 11a–c present the errors (Ex, Ey, and Ez) of axes X, Y, and Z in the whole space.

Ex:

Volumetric errors (X: (0 ~ −1500)mm; Y: (−2550 ~ −1950)mm; and Z: (−900 ~ 200)mm): 6 ~ 14 μm.

Ey:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−2550 ~ −1050)mm; and Z: (−240 ~ 200)mm): 0 ~ 5 μm.

Ez:

Volumetric errors (X: (−750 ~ 0)mm; Y: (−2550 ~ −1050)mm; and Z: (−900 ~ 200)mm): < 7 μm.

The volumetric errors are compensated by means of our system compensation software on the traditional error model comprehensive model while optimization of Abbé errors is taken. Then, simulation and quantitative evaluation of tooling volumetric errors are performed. The tooling volumetric error field is shown in Fig. 12.

Figure 12a–c present the errors (Ex, Ey, and Ez) of axes X, Y, and Z in the whole space.

Ex:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−2550 ~ −1500)mm; and Z: (−570 ~ 90)mm): < 10 μm.

Ey:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−1050 ~ −1500)mm; and Z: (−350 ~ 200)mm): 5 ~ 10 μm.

Ez:

Volumetric errors (X: (−1500 ~ 0)mm; Y: (−1200 ~ −1050)mm; and Z: (−790 ~ −570)mm): > 15 μm.

Quantitative evaluation of body diagonal

At present, evaluation of the spatial precision of a machine tool is usually based on its diagonal precision index. In a 3-axis CNC machine tool, there are 4 body diagonals which can reflect its overall spatial precision. In general, the precision of a machine tool can only be indicated while the diagonal precision indexes of 4 bodies are simultaneously high. There is no international standard for the body diagonal precision. Our findings show that the precision index of 4-body diagonal precision of a CNC machine tool can be controlled within 20 µm at the same time while its precision is very high. For evaluation of its spatial precision, a laser Doppler measuring instrument and a step diagonal measuring mirror group are utilized to measure its whole travel space. The measurement travel plan is shown in Fig. 13.

The sizes of the working space of our machine tool for measuring the diagonal by means of the laser step-by-step body are 1500 × 1500 × 1100 mm, which is divided into n = 11 grids. X, Y, and Z are measured step by step in each lattice, and the corresponding moving vectors of each step are (150, 0, 0), (0, 150, 0), and (0, 0, 110). As for the traditional error model, the measurements of the volume diagonal errors are shown in Fig. 14.

NPP, NPN, PPP, and PPN: diagonal errors prior to performance of compensation; and NPP′, NPN′, PPP′, and PPN′: body diagonal errors after performance of compensation.

Prior to performance of compensation, PPP, NPP, PPN, and NPN peak at −77.2 μm, −62.5 μm, −74.6 μm, and −66.7 μm, respectively. Rather, PPP′, NPP′, PPN′, and NPN′ peaks at −7.7 μm, −17.4 μm, −14.3 μm, and −18.7 μm, respectively, after performance of compensation.

The tooling volumetric errors are compensated by means of our compensation system and the traditional error model optimized based on the Abbé error, and the laser interferometer is utilized to measure the diagonal errors and quantitatively evaluate the volumetric errors. The measurements are shown in Fig. 15.

NPPα, NPNα, PPPα, and PPNα: diagonal errors prior to performance of compensation; and NPP′α, NPN′α, PPP′α, and PPN′α: body diagonal errors after performance of compensation.

Prior to performance of compensation, NPPα, NPNα, PPPα, and PPNα peak at −76.5 μm, −65.5 μm, −79.7 μm, and −78.3 μm, respectively. Rather, NPP′α, NPN′α, PPP′α, and PPN′α peak at −4.2 μm, 9.4 μm, −7.1 μm, and −6.6 μm, respectively, after performance of compensation.

The Abbé error is a factor which is not considered in the traditional error models. Worse still, it affects not only the linear error measurements but also the precision of the traditional error model. Finally, it has an impact on compensation effects based on the traditional error model. The specific effects are shown in Table 2.

In terms of linearity errors, the linear errors of each axis for the traditional error measurements peak at 65.6 μm, 24.1 μm, and −77.2 μm, respectively. Rather, the actual maximum linear errors of each axis in case of consideration of the Abbé error are −62.4 μm, 26.1 μm, and −63.8 μm, respectively.

In terms of machine tool body diagonal errors: prior to performance of error compensation, the body diagonal error in the traditional error measurements peaks up to −77.2 μm, and the actual maximum body diagonal error data in case of consideration of the Abbé error is −79.7 μm. In contrast, the volume diagonal error in the traditional error measurements peaks up to −18.7 μm, and the actual maximum volume diagonal error data in case of consideration of the Abbé error is 9.4 μm.

Comparison and analysis of the specific error data indicate that the Abbé error greatly affect the linear errors, which has an impact on the compensation effects in turn. Compared with the traditional model, the traditional error model under consideration of the Abbé error has a better compensation effect, whose body diagonal falls by 9.3 μm.

7 Conclusions

At present, traditional error modeling methods do not consider effects of the Abbé error on the measurements of linear errors. For overcoming the above shortcomings, the tooling volumetric error model where the Abbé error has been taken into account was established here based on effects of the Abbé arm and the angle errors on the linear error measurements. Secondly, a quantitative precision evaluation method for the diagonal of the tool workspace and a Matlab-based simulation qualitative evaluation method were proposed according to the model. In addition, a volumetric error compensation system with functions of original error analysis, high-precision modeling, diagonal error calculation, and error field simulation was developed to verify the compensation effects of the fact that the Abbé error is taken into account. For evaluation of the effects of the Abbé error on the traditional volumetric error model, an example analysis was carried out. For a 3-axis machine tool, 3-axis linear error peak at 65.6 μm, 24.1 μm, and −77.2 μm without consideration of the Abbé error; the maximum diagonal errors of 4 bars are −62.5 μm, −66.7 μm, −77.2 μm, and −74.6 μm. Rather, the 3-axis linear errors peak at −62.4 μm, 26.1 μm, and −63.8 μm, and 4 maximum body diagonal errors are −65.5 μm, −78.3 μm, −76.5 μm, and −79.7 μm, respectively.

After performance of compensation, the maximum 3-axis linear errors are −15.3 μm, −12.8 μm and −19.2 μm; the maximum diagonal errors of 4 bars are −17.4 μm, −18.7 μm, −7.7 μm, and −14.3 μm respectively, while the Abbé error has been not taken into account. Rather, 3-axis linear errors peak at −16.7 μm, −14.2 μm, and −16.5 μm, and the maximum values of 4-bar diagonal errors are 9.4 μm, −6.6 μm, −4.2 μm, and −7.1 μm, respectively, in case of consideration of the Abbé error-based tooling error model. Our experimental results show that the evaluation of machine tool precision is more reasonable and the compensation precision is higher.

Data availability

Our experimental data for the measuring point errors to support the findings of this study are currently embargo, while the research findings are commercialized. Request for data, 12 months after publication of this article, will be considered by the corresponding author (zjjll123456@126.com).

References

Zhong X, Liu H, Mao X (2019) An optimal method for improving volumetric error compensation in machine tools based on squareness error identification. Int J Precis Eng Manuf 20:1653–1665

Zhang Z, Cai L, Cheng Q (2019) A geometric error budget method to improve machining accuracy reliability of multi-axis machine tools. J Intell Manuf 30:495–519

Mei B, Xie F, Liu X, Yang C (2021) Elasto-geometrical error modeling and compensation of a five-axis parallel machining robot. Precis Eng 69:48–61

Fu G, Fu J, Xu Y, Chen Z, Lai J (2015) Accuracy enhancement of five-axis machine tool based on differential motion matrix: geometric error modeling, identification and compensation. Int J Mach Tools Manuf 89:170–181

Liu H, Rasheed M, Younis H (2019) A line measurement method for geometric error measurement of the vertical machining center. SN Appl Sci 1:324–333

Schwenke H, Knapp W, Haitjema H, Weckenmann A, Schmitt R, Delbressine F (2008) Geometric error measurement and compensation of machines—an update. CIRP Ann 57:660–675

Wang H, Cao Y (2018) Influence of machining parameters on vibration characteristics of gear form grinding. J Ad Appl Math 3:73–81

Xia HJ, Peng WC, Ouyang XB, Chen XD, Wang SJ, Chen X (2017) Identification of geometric errors of rotary axis on multi-axis machine tool based on kinematic analysis method using double ball bar. Int J Mach Tools Manuf 122:161–175

I. 230–7 (2006) Test Code for Machine Tools-Part 7: Geometric accuracy of axes of rotation

ISO1328–1–2013 (2013) Cylindrical gears—ISO system of flank tolerance classification — part 1: definitions and allowable values of deviations relevant to flanks of gear teeth

Mayr J, Jedrzejewski J, Uhlmann E, Alkan Donmez M, Knapp W, Härtig F, Wendt K, Moriwaki T, Shore P, Schmitt R, Brecher C, Würz T, Wegener K (2012) Thermal issues in machine tools. CIRP Ann 61:771–791

Wang J, Guo J, Zhou B, Xiao J (2012) The detection of rotary axis of NC machine tool based on multi-station and time-sharing measurement. Measurement 45:1713–1722

De L, Lacalle LN, Lamikiz A, Ocerin O, Díez D, Maidagan E (2008) The Denavit and Hartenberg approach applied to evaluate the consequences in the tool tip position of geometrical errors in five-axis milling centers. Int J Adv Manuf Technol 37:122–139

Xia C, Wang S, Wang S (2020) Geometric error identification and compensation for rotary worktable of gear profile grinding machines based on single-axis motion measurement and actual inverse kinematic model. Mech Mach Theory 155:94–114

Nojedeh MV, Habibi M, Arezoo B (2011) Tool path accuracy enhancement through geometrical error compensation. Int J Mach Tools Manuf 51:471–482

Liu H, Miao E, Zhuang X (2018) Thermal error robust modeling method for CNC machine tools based on a split unbiased estimation algorithm. Precis Eng 51

Kim K (1991) Volumetric accuracy analysis based on generalized geomean multi-axis machine tools. Mech Mach Theor

Chen G, Xiang H, Chen J (2017) A method of measurement and modeling for volumetric errors of machine tools based on comprehensive compensation. Rev de la Fac de Ing 32:332–337

Zuo W, Li W (2019) Study on volumetric error model and identification method of 5-axis CNC machine tools. J Combined Mach Tools Autom Mach Technol 2:45–48

Zhang Y, Qin H, Yang Q, Li W (2019) error analysis and modeling of grinding system of cycloid wheel grinder of RV reducer. Combined Mach Tool Autom Process Technol 22:62–66

Niels B, Jun Q, Dominiek R (2017) Design and experimental validation of an ultra-precision Abbé-compliant linear encoder-based position measurement system. Precis Eng 47:197–211

Kim DM, Lee DY, Gweon DG (2007) A new nano-accuracy AFM system for minimizing Abbé errors and the evaluation of its measuring uncertainty. Ultramicroscopy 107:322–328

Jin T, Ji HD, Hou WM, Le YF, Shen L (2017) Measurement of straightness without Abbé error using an enhanced differential plane mirror interferometer. Appl Opt 56:607–610

Huang Y, Fan K, Lou Z (2020) A novel modeling of volumetric errors of three-axis machine tools based on Abbé and Bryan principles. Int J Mach Tools Manuf 151:103527

Wang H, Li TJ (2021) Tolerance analysis of the volumetric error of heavy-duty machine tool based on interval uncertainty. Int J Adv Manuf Technol 114:2185–2199

Zhang SY, He C, Liu XJ, Xu JH (2020) Kinematic chain optimization design based on deformation sensitivity analysis of a five-axis machine tool. Int J Adv Manuf Technol 21:2375–2389

Wang HW, Ran Y, Zhang SY, Li YL (2020) Coupling and decoupling measurement method of complete geometric errors for multi-axis machine tools. Appl Sci Basel 10:2169–2183

Acknowledgements

The authors would like to thank Lin Zhang, Xiangjie Wang, Chao Wang, Hua Xiang, Guangqing Tong, and Dianzhang Zhao for their contributions in the writing process and also want to thank the funding supports.

Funding

This work was supported by 2019 Central Government Guides Local Special Funds (No.: 2019ZYYD017), 2018 National Science and Technology Major Project (No.: 2018ZX04016001; 2018ZX04012001), Electromechanical Automotive Discipline Group Open Fund (No.: 2019XKQ2019001), and High-end CNC Machine Tools and Basic Manufacturing Equipment Technology Major Project (No.: 2019ZX04001024).

Author information

Authors and Affiliations

Contributions

Guohua Chen: conceptualization, methodology, formal analysis and writing; Lin Zhang: methodology, software, investigation and writing-original draft preparation; Xiangjie Wang: formal analysis; Chao Wang: software and visualization. Hua Xiang: software and methodology; Guangqing Tong: investigation; and Dianzhang Zhao: investigation.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, G., Zhang, L., Wang, X. et al. Modeling method of CNC tooling volumetric error under consideration of Abbé error. Int J Adv Manuf Technol 119, 7875–7887 (2022). https://doi.org/10.1007/s00170-021-08494-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08494-1