Abstract

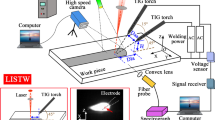

In order to improve the melting efficiency of double-TIG arc, based on the synchronous induction of pulsed laser to double-arc, the coupling-enhanced discharge phenomenon between double-arcs is studied in this paper. The melting efficiency of pulsed laser-induced double-arc is quantitatively analyzed. The physical characteristics of coupling double-arc are studied based on high-speed camera and spectral diagnosis technology. The physical model is established to discuss the particle migration during the coupling discharge, characterizing the movement state of electrons. The results show that Dla (horizontal distance between the tungsten electrode tip and laser beam axis) has a significant effect on the melting efficiency of the heat source. With the increase of Dla, there are three interaction relationships between the double-arc plasma and keyhole plasma: mutual interference, coupling-enhanced discharge, and no interaction. A suitable Dla can realize the synchronous induction of laser to double-arc plasma, forming a coupling double-arc; the heat source has a higher melting efficiency. The migration of particles in double-arc can be divided into four stages: double-arc free discharge stage, laser-induced initial stage, laser-induced contraction stage, and laser-induced stable stage. Under the induction of laser, the double-arc forms a common compressed conductive channel. The energy density of coupling double-arc reaches 9.3 times that of traditional double-arc, and the total electron kinetic energy increases by 38% compared with traditional double-arc.

Similar content being viewed by others

Availability of data and material

All the data have been presented in the manuscript.

Code availability

Not applicable.

References

Muñoz JA, Komissarov A, Mejía I, Hernández-Belmontes H, Cabrera J-M (2021) Characterization of the gas tungsten arc welding (GTAW) joint of Armco iron nanostructured by equal-channel angular pressing (ECAP). J Mater Process Tech 288

Singh A, Singh RP (2020) A review of effect of welding parameters on the mechanical properties of weld in submerged arc welding process. Mater Today: Proc 26:1714–1717

Balasubramanian TS, Balakrishnan M, Balasubramanian V, Manickam MAM (2011) Influence of welding processes on microstructure, tensile and impact properties of Ti-6Al-4V alloy joints. Trans Nonferrous Metal Soc 21(6):1253–1262

Balasubramanian V, Jayabalan V, Balasubramanian M (2008) Effect of current pulsing on tensile properties of titanium alloy. Mater Des 29(7):1459–1466

Cheng Z, Ye Z, Huang J, Yang J, Chen S, Zhao X (2020) Influence of heat input on the intermetallic compound characteristics and fracture mechanisms of titanium-stainless steel MIG-TIG double-sided arc welding joints. Intermetallics 127

Wu K, Cao X, Yin T, Zeng M, Liang Z (2019) Metal transfer process and properties of double-wire double pulsed gas metal arc welding. J Manuf Process 44:367–375

Ma Z, Zhuang M, Li M (2020) Effect of main arc voltage on arc behavior and droplet transfer in tri-arc twin wire welding. J Mater Res Technol 9(3):4876–4883

Chen J, Lu Y, Li X, Zhang Y (2012) An innovative GTAW process attains high-speed filler metal melting to compete with GMAW in deposition. Weld J 91:261–269

Reis RP, Scotti A, Norrish J, Cuiuri D (2013) Investigation on welding arc interruptions in the presence of magnetic fields: arc length, torch angle and current pulsing frequency influence. IEEE Trans Plasma Sci 41(1):133–139

Schwedersky MB, Gonçalves e Silva RH, Dutra JC, Reisgen U, Willms K (2018) Arc characteristic evaluation of the double-electrode GTAW process using high current values. Int J Adv Manuf Technol 98(1–4):929–936

Qin G, Meng X, Fu B (2015) High speed tandem gas tungsten arc welding process of thin stainless steel plate. J Mater Process Technol 220:58–64

Liu G, Xiong J, Tang L (2020) Microstructure and mechanical properties of 2219 aluminum alloy fabricated by double-electrode gas metal arc additive manufacturing. Addit Manuf 35

Scalet Rossini LF, Valenzuela Reyes RA, Spinelli JE (2019) Double-wire tandem GMAW welding process of HSLA50 steel. J Manuf Process 45:227–233

Zhang GJ, Leng XS, Wu L (2006) Physics characteristic of coupling arc of twin-tungsten TIG welding. Trans Nonferrous Metal Soc 16(4):813–817

Lu R, Wei H, Li F, Zhang Z, Liang Z, Li B (2020) In-situ monitoring of the penetration status of keyhole laser welding by using a support vector machine with interaction time conditioned keyhole behaviors. Opt Laser Eng 130

Xu L, Tang X, Zhang R, Lu F, Cui H (2021) Weld bead characteristics for full-penetration laser welding of aluminum alloy under electromagnetic field support. J Mater Process Tech 288

Hess A, Weber R, Heider A, Graf T (2010) Forced deep-penetration welding with low-power second-harmonic assistance of cw copper welding with 1 μm wavelength. Phys Procedia 5:29–36

Steen W (1980) Arc augmented laser processing of materials. J Appl Phys 51(11):5636–5641

Meng Y, Gao M, Zeng X (2018) Quantitative analysis of synergic effects during laser-arc hybrid welding of AZ31 magnesium alloy. Opt Laser Eng 111:183–192

Ragavendran M, Chandrasekhar N, Ravikumar R, Saxena R, Vasudevan M, Bhaduri AK (2017) Optimization of hybrid laser-TIG welding of 316LN steel using response surface methodology (RSM). Opt Laser Eng 94:27–36

Zhu Z, Wang W, Li Y, Chen H (2019) Effect of laser-arc offset and laser-deviation angle on the control of a Ti-Al interlayer. J Mater Process Technol 271:336–345

Casalino G, Mortello M, Leo P, Benyounis KY, Olabi AG (2014) Study on arc and laser powers in the hybrid welding of AA5754 Al-alloy. Mater Des 61:191–198

Shinn BW, Farson DF, Denney PE (2013) Laser stabilisation of arc cathode spots in titanium welding. Sci Technol Weld Join 10(4):475–481

Hu B, Ouden G (2005) Laser induced stabilisation of the welding arc. Sci Technol Weld Join 10:76–81

Li Z, Wang W, Wang X, Li H (2010) A study of the radiation of a Nd:YAG laser–MIG hybrid plasma. Opt Laser Technol 42(1):132–140

Liu L, Xu X, Zhu Y (2020) Study on synchronous induction of arc plasma by laser in laser-double TIG hybrid welding. Opt Laser Eng 133

Chen M, Xin L, Zhou Q, He L, Wu F (2018) Effect of laser pulse on alternative current arc discharge during laser-arc hybrid welding of magnesium alloy. Opt Laser Eng 100:208–215

Liu L, Chen M (2011) Interactions between laser and arc plasma during laser–arc hybrid welding of magnesium alloy. Opt Laser Eng 49(9–10):1224–1231

Sabbaghzadeh J, Dadras S, Torkamany MJ (2007) Comparison of pulsed Nd : YAG laser welding qualitative features with plasma plume thermal characteristics. J Phys D Appl Phys 40(4):1047–1051

National Institute of Standards and Technology (2019) database. https://www.nist.gov/pml/atomic-spectra-database. Accessed 25 Dec 2019

Griem H (1974) Spectral line broadening by plasma. Academic Press, New York

Ready J (1978) Industrial applications of lasers. Academic Press, New York

Mazar Atabaki M, Nikodinovski M, Chenier P, Ma J, Liu W, Kovacevic R (2014) Experimental and numerical investigations of hybrid laser arc welding of aluminum alloys in the thick T-joint configuration. Opt Laser Technol 59:68–92

Guo Z, Yin S, Qian Z, Liao H, Gu S (2015) Effect of the deviation of the current density profile center on the three-dimensional non-transferred arc plasma torch. Comput Fluids 114:163–171

Liu LM, Shi JP, Hou ZL, Song G (2018) Effect of distance between the heat sources on the molten pool stability and burn-through during the pulse laser-GTA hybrid welding process. J Manuf Process 34:697–705

Jiang QX, Zou YR, Du D (2016) Measurement of current density distribution in welding arc space based on image analysis. Trans China Weld Inst 37(8):101–104

AnTeng H, ChangGu C (1985) Welding arc phenomenon. Machinery Industry Press

Meng Y, Gao M, Zeng X (2018) Effects of arc types on the laser-arc synergic effects of hybrid welding. Opt Express 26(11):14775–14785

Funding

This work was supported by the National Key R&D Program of China (2018YFB1107902) organization name: Ministry of Science and Technology of the People’s Republic of China.

Author information

Authors and Affiliations

Contributions

Liming Liu: conceptualization, funding acquisition.

Xinkun Xu: roles/writing—original draft, methodology, formal analysis.

Guomin Xu: data curation, supervision.

Zhaodong Zhang: writing—review and editing, validation.

Corresponding author

Ethics declarations

Ethics approval

The paper follows the guidelines of the Committee on Publication Ethics (COPE).

Consent to participate

The authors declare that they all consent to participate in this research.

Consent for publication

The authors declare that they all consent to publish the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, L., Xu, X., Xu, G. et al. Effect of laser on double-arc physical characteristics in pulsed laser-induced double-TIG welding. Int J Adv Manuf Technol 119, 1515–1529 (2022). https://doi.org/10.1007/s00170-021-08277-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08277-8