Abstract

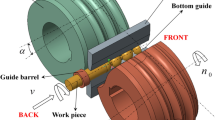

Cold helical rolling (CHR) is one of the most effective ways to produce small-diameter steel balls. In this study, one kind of work hardening model was established and implemented into Simufact 15.0 to investigate the work hardening phenomenon in the cold forming process. Firstly, based on the helical rolling theory, a set of finite element (FE) simulations was developed. The influence of CHR parameters, including the starting height of convex rib, forming area length, and rolling inclination angle, on the forming process was studied via simulation. Furtherly, the CHR process experiment and FE simulation were carried out; the results showed that the FE simulation was in good agreement with the experimental results and consistent with the predicted value of the theoretical calculation. Finally, the evolution of effective strain, effective stress, rolling force, work hardening, and microstructure during the cold helical rolling of Φ 5.2-mm steel balls was investigated via FE. As a result, the evolution trend of hardness was consistent with that of dislocation density, indicating that the model is credible. Besides, the microstructure of the steel ball at different positions further verified this point.

Similar content being viewed by others

Availability of data and materials

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

He T, Huo Y (2018) A new damage evolution model for cold forging of bearing steel-balls. Trans Indian Inst Met 71:1175–1183. https://doi.org/10.1007/s12666-017-1253-0

Hu ZH, Hua L (2010) Technology of rotary metal forming. Chemical Industry Press, Beijing

Pater Z, Tomczak J, Bartnicki J, Lovell MR, Menezes PL (2013) Experimental and numerical analysis of helical-wedge rolling process for producing steel balls. Int J Mach Tools Manuf 67:1–7. https://doi.org/10.1016/j.ijmachtools.2012.12.006

Pater Z, Tomczak J, Bartnicki J, Bulzak T (2018) Thermomechanical analysis of a helical-wedge rolling process for producing balls. Metals 11:862

Yang S, Chen C (2001) The surface geometry of rollers with skew rolling of steel balls. Proc Inst Mech Eng Part C J Mech Eng Sci 215:523–532. https://doi.org/10.1243/0954406011520922

Wang QX, Wang QP, Xiao JM (1995) Study on the method for groove design in the helical rolling of steel balls. J Mater Process Technol 55:340–344. https://doi.org/10.1016/0924-0136(95)02028-4

Tomczak J, Pater Z, Bulzak T (2014) Designing of screw impressions in the helical rolling of balls. Arch Civ Mech Eng 14:104–113. https://doi.org/10.1016/j.acme.2013.07.004

Huo Y, He T, Wang B, Zheng Z, Xue Y (2020) Numerical prediction and experimental validation of the microstructure of bearing steel ball formation in warm skew rolling. Metall Mater Trans A Phys Metallur Mater Sci 51:1254–1263. https://doi.org/10.1007/s11661-019-05589-z

Gontarz A, Tomczak J, Pater Z, Bulzak T (2019) Effect of the forming zone length on helical rolling processes for manufacturing steel balls. Materials (Basel) 12. https://doi.org/10.3390/ma12182917

Chyła P, Pater Z, Tomczak J, Chyła P (2016) Numerical analysis of a rolling process for producing steel balls using helical rolls. Arch Metall Mater 61:485–492. https://doi.org/10.1515/amm-2016-0085

Cao Q, Hua L, Qian DS (2015) Finite element analysis of deformation characteristics in cold helical rolling of bearing steel-balls. J Cent South Univ 22:1175–1183. https://doi.org/10.1007/s11771-015-2631-6

Pater Z, Tomczak J, Bulzak T, Cyganek Z, Andrietti S, Barbelet M (2018) An innovative method for producing balls from scrap rail heads. Int J Adv Manuf Technol 97:893–901. https://doi.org/10.1007/s00170-018-2007-9

Pater Z, Tomczak J, Bulzak T (2017) A cross wedge rolling process for forming 70 mm diameter balls from heads of scrap railway rails. Procedia Manufacturing 11:466–473. https://doi.org/10.1016/j.promfg.2017.07.137

Pater Z, Tomczak J, Wójcik A, Bulzak T (2019) Physical Modelling of the Ball-Rolling Processes. Metals (Basel ) 9:35. https://doi.org/10.3390/met9010035

Lu XC, Zhang X, Shi MX, Roters F, Kang GZ, Raabe D (2019) Dislocation mechanism based size-dependent crystal plasticity modeling and simulation of gradient nano-grained copper. Int J Plast 113:52–73. https://doi.org/10.1016/j.ijplas.2018.09.007

Lindroos M, Valtonen K, Kemppainen A, Laukkanen A, Holmberg K, Kuokkala V (2015) Wear behavior and work hardening of high strength steels in high stress abrasion. Wear 322–323:32–40. https://doi.org/10.1016/j.wear.2014.10.018

Shterner V, Timokhina IB, Beladi H (2016) On the work-hardening behaviour of a high manganese TWIP steel at different deformation temperatures. Mater Sci Eng A 669:437–446. https://doi.org/10.1016/j.msea.2016.05.104

Hariharan K, Hariharan K, Barlat F, Barlat F (2019) Modified Kocks–Mecking–Estrin model to account nonlinear strain hardening. Metall Mater Trans A Phys Metall Mater Sci 50:513–517. https://doi.org/10.1007/s11661-018-5001-9

Pandre S, Mhatre V, Kotkunde N, Kumar Singh S (2020) Strain hardening behavior of DP 590 steel using dislocation density based Kock-Mecking model. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2020.02.810

Lin J, Liu Y (2003) A set of unified constitutive equations for modelling microstructure evolution in hot deformation. J Mater Process Technol 143–144:281–285. https://doi.org/10.1016/S0924-0136(03)00472-2

Xiao WC, Wang BY, Wu Y, Yang XM (2018) Constitutive modeling of flow behavior and microstructure evolution of AA7075 in hot tensile deformation. Mater Sci Eng A 712:704–713. https://doi.org/10.1016/j.msea.2017.12.028

XL R (2019) Study on Hardening Behavior and Mechanism of Bearing Rings in Ultrasonic Rolling Extrusion. Master Henan University Of Science And Technology, https://kns.cnki.net/kcms/detail/detail.aspx?FileName=1019658726.nh&DbName=CMFD2019

Hua L, Qian DS, Pan LB (2008) Analysis of plastic penetration in process of groove ball-section ring rolling. J Mech Sci Technol 22:1374–1382. https://doi.org/10.1007/s12206-008-0308-x

Funding

This work was supported by the Beijing Laboratory of Modern Transportation Metal Materials and Processing Technology. This work was also supported by the Beijing Key Laboratory of Metal Forming Lightweight.

Author information

Authors and Affiliations

Contributions

Shengqiang Liu: software, investigation, validation, methodology, writing—original draft. Jinping Liu: project administration, supervision, funding acquisition. Hao xu: supervision, writing—reviewing and editing. Zhipeng Wang: methodology, writing—reviewing and editing. Jinxia Shen: writing—reviewing and editing. Baoyu Wang: administration, supervision, funding acquisition.

Corresponding authors

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

All the authors listed have approved the manuscript that is enclosed.

Consent to participate

Applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, S., Liu, J., Xu, H. et al. Experimental and numerical study of cold helical rolling of small-diameter steel balls. Int J Adv Manuf Technol 119, 599–613 (2022). https://doi.org/10.1007/s00170-021-08076-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08076-1