Abstract

In almost every industry, polymer materials are in high demand in recent years due to their lightweight and easy formability. However, eco-friendly, cost-efficient and defect-free joining of polymers is a major concern. In this article, a novel approach is taken for friction stir welding of polypropylene by implementing a double-side welding technique. The effect of tool rotational speed on construction and properties of the welded joints are studied. The torque and forces exerted on the tool during double-side welding are compared with single-side welding. Cross-sectional morphology examination using optical and scanning electron microscope reveals defect-free sound welding by double-side weld with uniform material flow. The molecular bonds of the welded specimens are examined by FTIR analysis. The double-side welding technique yields superior joints in terms of tensile strength and flexural strength than the joints obtained by single-side welding.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, the application of lightweight materials is increasing gradually to meet the demand for reducing engineering product weight. Due to lightweight, high specific strength, low manufacturing cost thermoplastic materials is gaining the attention of the manufacturing sector towards itself [1, 2]. In automobile industries, thermoplastics are used to manufacture seating, bumpers, dashboard, fuel systems, liquid reservoirs, under-bonnet components, body (including panels), electrical components, interior trim, exterior trim, lighting, etc. [3]. In a wide pool of commercially available thermoplastics, polypropylene (PP) is one of the most lucrative choices in industrial application due to its very low cost, the high degree of processability and design freedom. Although PP can be easily transformed into different shapes, joining is essential to produce complex shapes and large parts.

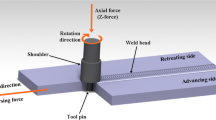

One of the well-established techniques of thermoplastic joining is adhesive bonding. However, it requires joint preparation and surface cleaning and is also problematic to handle and slow to cure. Mechanical fasteners do not provide a leak-tight joint. In application, the localized stresses may even cause them to pull free from the polymeric material. The hot tool welding takes a long cycle time. The expensive nature and emission of the harmful gas during laser welding limit it from becoming the go-to method for thermoplastic joining. The high sound level (90–95 dB) of vibration welding can cause noise pollution. Ultrasonic welding was found not to be a suitable method to weld large joints in a single operation [4,5,6]. Later friction stir welding (FSW) was employed which provided better joint efficiency without emitting toxic gases [7]. In FSW, a rotating tool plunges into the joint line, and the rubbing action between tool and workpiece produces frictional heat that results in joining of the workpiece [8]. A schematic representation of the friction stir welding (FSW) process is shown in Fig. 1.

Bozkurt [9] reported that the tool rotational speed, traverse speed and tool tilt angle were the major significant process parameters with an influence of about 73.85%, 20.18% and 5.96%, respectively, on welding. During linear friction stir welding of polycarbonate sheets, Lambiase et al. [10] observed that with the increase in tool tilt angle, processing temperatures and forging loads were increased. In addition to those factors, moderate plunge depth was also essential to produce defect-free welding in terms of the absence of cavities, blowholes and blisters. Mendes et al. [11] observed that in the FSW of 6-mm acrylonitrile butadiene styrene (ABS), more than 1.5 kN axial force was required to produce defect-free welds. The tool is also one of the most significant aspects in this process, as it determines the amount of material to be stirred as well as the movement of plasticized material. From extensive literature on FSW of thermoplastic, it is well evident that the cylindrical threaded tool gives better joint efficiency in butt joint [12] and also threaded cylindrical pin produces less transverse force during the welding [13]. During FSW, the tool plunges up to a certain limit while maintaining a minimum gap between the pin and back supporting plate (Fig. 1). The gap is essential to avoid the collision between the tool pin and the supporting plate. In case of welding of metals, owing to their high thermal conductivity, the heat at the bottom of the pin is getting transferred up to the bottom of the plate, and welding takes place. As the thermal conductivity of thermoplastics is low, sometimes root defect remains at that gap left between the pin and supporting plate [14]. Due to the low thermal conductivity of polymer, during FSW, heat dissipation in the stir zone is hindered, and consequently, plasticity is restricted. As a result, the polymer subjected to FSW is fractured by the high share force exerted by the rotating tool. The fractured solid particles remain in the stir zone and increase overall viscosity of the stir zone. Thus, root tunnel defect is formed during FSW of polymers [15]. This phenomenon is very common in the FSW of thermoplastic [16]. To overcome this, Arici and Sinmaz adopted double pass approach for FSW of 5-mm polyethylene plate [17]. They used a tool with a pin height of approximately half of the plates to be welded and carried out two passes in either side of the plates. Hejazi [18] also employed the double-side friction stir welding for AA6061-T913 alloy and obtained a significant improvement in ultimate tensile strength compared to single-side welding. Delijaicov et al. [19] performed dissimilar FSW of AA7181-T7651 and AA7475-T7351 aluminium plates using top, bottom, bobbin and double-side methods and observed that among these four methods, double-side and bobbin processes were able to produce the defect-free weld.

Therefore, in the present study, 6-mm polypropylene plates were joined through single-side and double-side FSW techniques. During welding, different forces employed on the tool pin were measured. The microstructures of the joints were studied with an emphasis on the constituents present in the weld zone. The mechanical properties of the welded joints were examined in terms of microhardness, tensile strength and flexure strength.

2 Experimental procedure

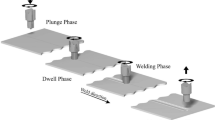

Experimental setup of the FSW machine is shown in Fig. 2. The specification of the FSW machine is presented in Table 1. In the present investigation, 6-mm-thick PP plates with 60-mm width and 100-mm length were butt welded. Two different welding techniques were employed in the present study. One is single-side welding (S), and the other is double-side welding (D) (Fig. 3a, b). For double-side welding, after performing welding on the first side (D1), the welded material was normally cooled down to room temperature before performing the welding in the opposite side (D2). Two different tools were used for the welding of the PP plates. The schematic representation and the tools used for experimentation are shown in Fig. 4. Both the tools were made of heat-treated tool steel with 16-mm shoulder diameter and 5-mm pin diameter. The chemical compositions of tool material are given in Table 2. The pins were right-hand threaded with 1-mm pitch length. However, the pin heights for the tools were different. The tool with a pin length of 5.5 mm was used for single-side welding (Fig. 4a), and the tool with a pin height of 3.5 mm was used for double-side welding (Fig. 4b).

All the welding were performed at 1° tilt angle with tool traverse speeds of 0.3 mm/s. Tool rotational speed 700, 750 and 800 rpm were chosen for welding from pilot experiments in the clockwise direction, as the clockwise rotation moves material downwards for right-hand threaded pin [13]. The pin was plunged in the material at a speed of 20 mm/s, and the plunging depth was kept 0.1 mm throughout the investigation. After plunging the tool was dwelled for 4 s. The spindle torque, Z-force and X-force were measured by strain gauge type load cell associated with NI LabView software installed in the machine. Strain gauge load cell offers highly accurate measurement by converting mechanical changes into electrical signals for measuring forces and torque. Z-force measurement, X-force measurement and torque measurement load cells are connected with a hydraulic actuator, machine bed and spindle, respectively (Fig. 2). After performing the butt welding with different process parameters, various test specimens were prepared as shown in Fig. 5. Specimens were prepared from the welded joints according to ASTM E 2015-04 [20] standard for morphology characterization by optical microscope as well as by scanning electron microscope (SEM). The Fourier transform infrared spectroscopy (FTIR) of base material and welded specimens was conducted to understand the chemical changes that occurred during the welding process. In order to determine the joint efficiency, tensile test samples were prepared as per the ASTM D638-14 [21] standard. Tensile tests were carried out on an Instron-8801 machine at room temperature (25 °C) with a constant crosshead speed of 0.5 mm/min. Three-point flexural tests were performed according to the ASTM D790-17 [22] standard. For the single-side weld specimen, the weld root was in tension. The fracture surface of the tensile specimen was analysed by SEM. The Vickers microhardness was measured for the weld specimen with an applied load of 25 g with a dwell time of 10 s. Hardness values were taken at 1-mm distance in 6 different layers to evaluate the distribution over the welded specimens.

3 Results and discussion

3.1 Variation of spindle torque and forces on the FSW tool

During deformation, the plasticized material exerts force against the tool rotation. The force is measured automatically by the machine and is represented as spindle torque. From the average spindle torque vs. tool rotational speed graph (Fig. 6), it can be seen that for single-side welding, the average torque values are around 22%, 4% and 9% higher than the double-side welding at rotational speed 700 rpm, 750 rpm and 800 rpm, respectively. As the pin length is more in case of the single-side welding, the amount of material interaction is more compared to the double-side welding tool. Therefore, higher torque value is observed. Lambiase et al. [23] also observed that with increasing pin area, torque value increased during the friction stir spot welding of polycarbonate sheets. It is interesting to see that in the case of double-side welding, for reverse side (D2), the average spindle torque is lower than that of the first side (D1). During D2, some fraction of the material to be deformed by the tool is already deformed during D1. As the previously deformed material is weaker than the base material, the force against tool rotation by it is slightly less. However, with an increase in tool rotation from 700 to 750 rpm, the average torque value decreases. This phenomenon is consistent for both the tools. The increase in tool rotation enables more material softening and therefore reduces the opposing force to the tool rotation [24]. With further increase in tool rotation from 750 to 800 rpm, the average torque value increases marginally due to the sticking property of the material at high temperature.

Axial force or Z-force is defined as the tool pressure towards the substrate during the welding. Axial force vs. time during the welding is shown in Fig. 7a–c. From the figure, it is observed that there is a sudden hike of Z-force at the initial stage followed by the rapid decrease in force value, and thereafter it stabilizes for the entire welding process. At the initial stage, the tool penetrates into the substrate until the shoulder touched the plate surface. At that time, the material does not get plasticized properly [25]. The unplasticized solid materials come out from the tool pin area and coagulate at the bottom portion of the shoulder and create maximum pressure on the tool. During dwelling material under the tool softens rapidly, and a drastic decrease in force is observed. With further advancement of the tool, the rate of plasticization is nearly same throughout the welding. Hence, stabilization of Z-force is observed. It is seen that for single-side welding (S), the value of Z-force is higher than that of the double-side welding (D1, D2). During the friction stir welding, the primary frictional heat source is the tool shoulder, whereas the pin acts as the second companion in heating. As a result, material near the shoulder gets maximum heat and becomes highly plasticized. As thermoplastic is less thermally conductive, a small fraction of shoulder heat is able to transfer through the weld material to the bottom area of the tool pin region. The bottom area of the weld material plasticizes only by the pin-workpiece frictional heat. Hence, it becomes comparatively less softened than the near-shoulder material [7]. However, in case of double-side welding, owing to shorter pin length, both shoulder heat and pin heat have a significant influence on the material at the bottom of the pin. Therefore, by using a shorter tool, material plasticization throughout the stir zone is nearly uniform. Due to the uniformity of material softening by a shorter tool, the decrease in Z-force is observed. However, for both the tools, welding with 750 rpm yields to most stabilized Z-force (Fig. 7b). The frictional heat generated at low rpm is not enough to properly soften the material at weld zone. The adequate amount of heat supplied by the tool at 750 rpm results in uniform laminar material flow. The high rotational speed results in deterioration of material in the form of small chips. The fluctuation of Z-force at high rpm indicates the inconsistent material response due to the presence of chips. During PP welding, Banjare et al. [26] also found that at high tool rotational speed, the formation of the chip is high.

The variation of force experienced by the tool opposite to the weld direction namely the traverse force or X-force is shown in Fig. 7d–f. However, for all parametric condition, it is observed that the X-force developed during the welding of single-side welds is higher than the double-side welds. The pin volume of the tool used in single-side welding is higher than (~ 36%) the tool used in double-side welding. As a result, the occupancy area of the tool pin is more in case of the single-side weld. Hence, higher X-force is obtained during single-side welding.

3.2 Microstructural characterization of welded joints

The cross-sections of the welds produced by the single-side and double-side welding at 750 rpm are shown in Fig. 8. Presence of root defect at the joint line is evident in the macrograph of single-side welding (Fig. 8a). This is due to insufficient heat flow at the bottom of the tool pin. Arici and Sinmaz [17] also observed root defect during the FSW welding of polyethylene plates. Also, due to the low heat and consequently improper softening at bottom portion, undeformed materials come to top surface with material flow. As a result, solid chips partials can be noticed to be trapped at the weld surface. As discussed earlier, due to the low thermal conductivity of polypropylene, at the bottom portion of the weld material outside the stir zone, the temperature rise by heat generated at tool shoulder is negligible. The heat generated by pin at the lower portion of the stir zone also does not get transferred outside of the stir zone due to the low conductivity. As a result, at the bottom portion, two different temperature zones are formed. Due to this mismatch of temperature between stir zone and adjacent to the stir zone, crack formed in advancing wall after cooling which is revealed by SEM (Fig. 8b). Buffa et al. [27] also encountered a similar scenario during the FSW of AA7075 alloy. Also, the magnified view of the stir zone of single-side welding (Fig. 8c) reveals turbulent material flow which leads to the formation of microvoids. Nath RK et al. [7] also observed turbulent material flow during FSW of PP sheet. The cross-sectional macrograph and weld surface images of double-side weld nugget (Fig. 8d) exhibit similar weld surface on both sides with absence of chip. The SEM image reveals good bonding of stir zone with advancing side without any crack (Fig. 8e). Although near the edges of pin, a very few microvoids can be observed (Fig. 8e, g), and the middle of the stir zone is free of any voids (Fig. 8f). Also, the overall uniformity in material flow is better for double-side welding than the single-side welding owing to availability of sufficient amount of heat at the entire stir zone (Fig. 8e–g).

The FTIR spectra for base material as well as the welds obtain by single-side and double-side welding with tool rotational speed of 750 rpm are shown in Fig. 9a–c. The spectrum of polypropylene contains major strong bands located at 2950 cm−1, 2918 cm−1, 2836 cm−1, 1456 cm−1, 1376 cm−1, 1166 cm−1, 974 cm−1 and 842 cm−1. The bands at 2950 cm−1, 2918 cm−1 and 2836 cm−1 indicate symmetric and asymmetric stretching of C-H group. The 1456 cm−1 band denotes asymmetric deformation vibration of a methyl group, whereas the band at 1376 cm−1 refers to symmetric deformation vibration of the same. The bands at 1166 cm−1, 974 cm−1 and 842 cm−1 belong to crystalline bands. The IR spectrum of the double-side welded sample is compared with the base material spectrum, and it is found to be almost consistent with parent material. However, additional peaks are observed at 1718 cm−1 and 1050 cm−1 band in single-side welding. The 1718 cm−1 band is due to the stretching of C=O (aliphatic ketones) group which may be due to oxidation occurred during the welding process, whereas the band at 1050 cm−1 denotes the stretching of C-O group. At 1658 cm−1band, chain braking phenomenon occurred in both welding conditions. In double-side welding, most of the internal structures remain intact due to high relaxation time as the local heat input, in this case, is high. During the butt joining of 5-mm-thick high-density polyethylene, Vijendra and Sharma [28] also observed that higher relaxation time helps in preserving the internal structure of welds.

3.3 Tensile strength and flexural strength

From the stress vs. strain graph (Fig. 10), it is observed that double-side welded FSW specimens exhibit higher weld strength compared to the single-side welds for all parametric condition. It may be due to the presence of root defect in case of single-side FSW weld which reduces the effective cross-section of the welded joints. It is also observed that with an increase in tool rotational speed from 700 to 800 rpm, the joint strength increases for the single-side welding. During tensile testing of 6-mm PP friction stir welded butt joint, Sahu et al. [29] achieved 59.82% joint strength efficiency with respect to the base material. However, in the case of double-side welding, at 750 rpm maximum joint strength of around 68% of the base material is achieved. With an increase in tool rotational speed, the frictional heat generated by the FSW tool is high. At high temperature, material sufficiently softens leading to proper mixing at the weld nugget. For double-side welding, at the 750 rpm, the tool provides effective heat at which the weld material of stir zone mixes properly. Azhiri et al. [30] reported that high level of tool rotational speed resulted in sufficient heat input, which improved the stirring action as well as both the tensile and impact strengths of the weld joint. Whereas increasing the rotational speed to 800 rpm generates a sticking condition and hereby prevents proper material mixing [31]. Moreover, with the increase of the rotational speed, residual stress of the joints also increases leading to decrease of the weld strength [32]. As a result, double-side welding at 750 rpm exhibits the best joint strength within the experimental domain. Also, it is observed from the stress vs. strain graph (Fig. 10) that the elongation is less in the case of single-side welding. It may be due to the presence of defects at the weld joint.

The presence of fibrillars in the fractography of tensile tested specimens (Fig.11) as well as the stress-strain curves (Fig.10) suggests that the mode of failure of the welded joints is ductile [33]. It can be seen that for single-side welding, the fibrillars near the shoulder region are longer compared to the bottom region (Fig. 11a–c). More flat zones at the fracture surface of the bottom region suggest improper mixing at the bottom region of the tool which is consistent with microstructural observation. Also, it is evident from the fracture surface that during tensile test, the crack present in the advancing side propagates, and thereby final fracture takes place [34]. However, in the case of the double-side weld, two different fracture mechanisms can be observed (Fig. 11d–f). One is direct shear, and another is sliding shear deformation as shown in Fig. 11e and Fig. 11f, respectively. For double-side welding, cracks initiate at the retreating side of both passes. As the retreating walls of the first weld and second weld are opposite to each other, with the crack propagation, sliding shear deformation along the centre line occurs.

In order to analyse the flexural behaviour with tool rotational speed, the flexural strength with different parametric welding conditions is shown in Table 3. It can be observed that for all parametric condition, double-side welds exhibit higher flexural strength compared to the single-side welds, as the single-side welds are comprised of root defect in the joint line. Also, it is evident that the flexural strength increases with the increase of tool rotational speed for both the welding conditions. The maximum flexural strength of 32.18 MPa (about 78.49% of the base material) is achieved for the double-side weld with 800 rpm.

3.4 Microhardness

Figure 12a, b reveal the Vickers microhardness (HV) distribution for single-side and double-side weldments obtained at 750 rpm. These distribution patterns are consistent for all single-side and double-side welded specimens, respectively. It is evident that the microhardness value at stir zone decreases for both the welding conditions (i.e. single-side welding and double-side welding). Similar behaviour of microhardness variation was observed by Moreno-Moreno et al. [35] and Elyasi et al. [36]. The stirring action of the tool results in the change of molecular weight or crystallinity of the weld material [37]. The cutting of molecular chains by stirring action decreases the melt viscosity and thereby stimulates the material flow. Also, the heat generated by the tool has a significant influence on breaking of molecular chains. Hence, the softening of material at the stir zone is observed. In single-side welding, average stir zone microhardness of 3.8 HV0.025 is observed with variation from 5.9 to 2.9 HV0.025. The stir zone of double-side welding exhibits an average microhardness of 3.9 HV0.025 with variations from 3.9 to 2.9 HV0.025. It can also be observed that for single-side welding, the material becomes softer at the retreating side of the welded joints compared to the advancing side. It is due to the availability of more heat at the retreating side than the advancing side [7]. However, the double-side welded specimen exhibits the least microhardness at the centre line region. The material at the centre line region encounters the stirring and heating twice. This leads to more chain breaking and therefore weakening the material compared to other portions of the stir zone. Away from stir zone, up to some extent, a slight reduction in microhardness compared to the base material is observed in both advancing and retreating sides. As no mechanical deformation happens in those regions, they may be defined as the heat-affected zone.

4 Conclusions

In the present investigation, 6-mm polypropylene plates were joined by the FSW to study the influence of two different welding conditions such as single-side welding and double-side welding on the microstructure and mechanical properties of the joints. The main findings are summarized below:

-

During the double-side friction stir welding of 6-mm polypropylene plates, the FSW tool encounters lower torque and forces than the single-side welding due to reduced amount of material interaction and uniform heating owing to short pin.

-

Use of double-side FSW is able to produce defect-free welding with the laminar material flow in the stir zone.

-

FTIR analysis reveals that double-side weld seam exhibits chemical similarity with the base material, whereas the absorption band at 1718 cm−1 and 1050 cm−1 reveals that oxidation occurs during single-side welding.

-

The tensile properties of double-side welded joints are higher compared to the single-side welded joints as it is comparably defect free along with improved material mixed transition zone. However, under tensile loading, all the welded specimens get fractured in ductile mode.

-

With an increase in tool rotation speed, the tensile properties of single-side weld improve owing to higher heat input. However, in the case of double-side welding, tool rotation speed of 750 rpm yields the highest tensile strength of 15.4 MPa.

-

Flexural strength for both welding conditions improves with the increase in tool rotational speed. Moreover, single-side weld exhibits lower flexural strength than double-side welding due to the presence of a defect in the weld seam.

-

Although lower average microhardness is achieved for double-side weld compared to single-side weld, due to uniform mixing by improved material flow, the microhardness variation in stir zone of the double-side weld is also less.

Data availability

Data and materials associated in the article cannot be shared at this time as these are part of ongoing research work.

References

Maddah HA (2016) Polypropylene as a promising plastic: a review. Am J Polym Sci 6(1):1–11. https://doi.org/10.5923/j.ajps.20160601.01

Ayrilmis N, Jarusombuti S, Fueangvivat V, Bauchongkol P, White RH (2011) Coir fiber reinforced polypropylene composite panel for automotive interior applications. Fibers Polym 12:919–926. https://doi.org/10.1007/s12221-011-0919-1

Lyu MY, Choi TG (2015) Research trends in polymer materials for use in lightweight vehicles. Int J Precis Eng Manuf 16(1):213–220. https://doi.org/10.1007/s12541-015-0029-x

Amancio-Filho ST, dos Santos JF (2009) Joining of polymers and polymer–metal hybrid structures: recent developments and trends. Polym Eng Sci 49(8):1461–1476. https://doi.org/10.1002/pen.21424

Stokes VK (1989) Joining methods for plastics and plastic composites: an overview. PolymEng Sci 29(19):1310–1324

Troughton M (2008) Handbook of plastics joining. William Andrew Inc, Norwich

Nath RK, Maji P, Barma JD (2019) Development of a self-heated friction stir welding tool for welding of polypropylene sheets. J Braz Soc Mech Sci Eng 41:553. https://doi.org/10.1007/s40430-019-2059-2

Maji P, Ghosh SK, Nath RK, Karmakar R (2020) Microstructural , mechanical and wear characteristics of aluminum matrix composites fabricated by friction stir processing. J Braz Soc Mech Sci Eng 42:191. https://doi.org/10.1007/s40430-020-02279-5

Bozkurt Y (2012) The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater Des 35:440–445. https://doi.org/10.1016/j.matdes.2011.09.008

Lambiase F, Grossi V, Paoletti A (2020) Effect of tilt angle in FSW of polycarbonate sheets in butt configuration. Int J Adv Manuf Technol 107:489–501. https://doi.org/10.1007/s00170-020-05106-2

Mendes N, Loureiro A, Martins C, Neto P, Pires JN (2014) Effect of friction stir welding parameters on morphology and strength of acrylonitrile butadiene styrene plate welds. Mater Des 58:457–464. https://doi.org/10.1016/j.matdes.2014.02.036

Hajideh MR, Farahani M, Alavi SAD, Ramezani NM (2017) Investigation on the effects of tool geometry on the microstructure and the mechanical properties of dissimilar friction stir welded polyethylene and polypropylene sheets. J Manuf Process 26:269–279. https://doi.org/10.1016/j.jmapro.2017.02.018

Panneerselvam K, Lenin K (2012) Investigation on effect of tool forces and joint defects during FSW of polypropylene plate. Procedia Eng 38:3927–3940. https://doi.org/10.1016/j.proeng.2012.06.450

Strand RS (2004) Effects of friction stir welding o polymer microstructure. Master of Science Department of Mechanical Engineering, Brigham Young University

Mendes N, Neto P, Simão MA, Loureiro A, Pires JN (2016) A novel friction stir welding robotic platform: welding polymeric materials. Int J Adv Manuf Technol 85:37–46. https://doi.org/10.1007/s00170-014-6024-z

Derazkola HA, Simchi A (2018) Experimental and thermomechanical analysis of the effect of tool pin pro fi le on the friction stir welding of poly ( methyl methacrylate ) sheets. J Manuf Process 34:412–423. https://doi.org/10.1016/j.jmapro.2018.06.015

Arici A, Sınmaz T (2005) Effects of double passes of the tool on friction stir welding of polyethylene. J Mater Sci 40:3313–3316

Hejazi I, Mirsalehi SE (2016) Effect of pin penetration depth on double-sided friction stir welded joints of AA6061-T913 alloy. Trans Nonferrous Met Soc China 26:676–683. https://doi.org/10.1016/S1003-6326(16)64158-4

Delijaicov S, Rodrigues M, Farias A, Neves MD, Bortolussi R, Miyazaki M, Brandão F (2020) Microhardness and residual stress of dissimilar and thick aluminum plates AA7181-T7651 and AA7475-T7351 using bobbin, top, bottom, and double-sided FSW methods. Int J Adv Manuf Technol 108:277–287. https://doi.org/10.1007/s00170-020-05370-2

ASTM E2015-04(2014), Standard guide for preparation of plastics and polymeric specimens for microstructural examination, ASTM International, West Conshohocken, PA, 2014, www.astm.org

ASTM (2014) D638-14, Standard test method for tensile properties of plastics. ASTM International, West Conshohocken, PA www.astm.org

ASTM (2017) D790-17, Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. ASTM International, West Conshohocken, PA www.astm.org

Lambiase F, Paoletti A, Di Ilio A (2016) Effect of tool geometry on loads developing in friction stir spot welds of polycarbonate sheets. Int J AdvManufTechnol 87:2293–2303. https://doi.org/10.1007/s00170-016-8629-x

Sahu SK, Pal K, Mahto RP, Dash P (2019) Monitoring of friction stir welding for dissimilar Al 6063 alloy to polypropylene using sensor signals. Int J Adv Manuf Technol 104:159–177. https://doi.org/10.1007/s00170-019-03855-3

Paoletti A, Lambiase F, Di Ilio A (2016) Analysis of forces and temperatures in friction spot stir welding of thermoplastic polymers. Int J Adv Manuf Technol 83:1395–1407. https://doi.org/10.1007/s00170-015-7669-y

Banjare PN, Sahlot P, Arora A (2017) An assisted heating tool design for FSW of thermoplastics. J Mater Process Technol 239:83–91. https://doi.org/10.1016/j.jmatprotec.2016.07.035

Buffa G, Campanella D, Fratini L (2017) Enhancement of mechanical properties of FSWed AA7075 lap joints through in-situ fabrication of MMC. J Manuf Process 28:422–427. https://doi.org/10.1016/j.jmapro.2017.04.008

Vijendra B, Sharma A (2015) Induction heated tool assisted friction-stir welding (i-FSW): a novel hybrid process for joining of thermoplastics. J Manuf Process 20:234–244. https://doi.org/10.1016/j.jmapro.2015.07.005

Sahu SK, Mishra D, Mahto RP, Sharma VM, Pal SK, Pal K, Banerjee S, Dash P (2018) Friction stir welding of polypropylene sheet. Int J Eng Sci 21:245–254. https://doi.org/10.1016/j.jestch.2018.03.002

Azhiri RB, Sola JF, Tekiyeh RM, Javidpour F, Bideskan AS (2019) Analyzing of joint strength, impact energy, and angular distortion of the ABS friction stir welded joints reinforced by nanosilica addition. Int J Adv Manuf Technol 100:2269–2282. https://doi.org/10.1007/s00170-018-2761-8

Ishraq MY, Maqsood S, Naeem K, Abid M, Omair M (2019) Analysing significant process parameters for friction stir welding of polymer composite. Int J Adv Manuf Technol 105:4973–4987. https://doi.org/10.1007/s00170-019-04548-7

Gao J, Li C, Shilpakar U, Shen Y (2016) Microstructure and tensile properties of dissimilar submerged friction stir welds between HDPE and ABS sheets. Int J Adv Manuf Technol 87:919–927. https://doi.org/10.1007/s00170-016-8539-y

Eslami S, Miranda JF, Mourão L, Tavares PJ, Moreira PMGP (2018) Polyethylene friction stir welding parameter optimization and temperature characterization. Int J Adv Manuf Technol 99:127–136. https://doi.org/10.1007/s00170-018-2504-x

Lambiase F, Grossi V, Paoletti A (2019) Advanced mechanical characterization of friction stir welds made on polycarbonate. Int J Adv Manuf Technol 104:2089–2102. https://doi.org/10.1007/s00170-019-04006-4

Moreno-Moreno M, Romero YM, Zambrano HR, Restrepo-Zapata NC, Afonso CRM, Unfried-Silgado J (2018) Mechanical and thermal properties of friction-stir welded joints of high density polyethylene using a non-rotational shoulder tool. Int J Adv Manuf Technol 97:2489–2499. https://doi.org/10.1007/s00170-018-2102-y

Elyasi M, Derazkola HA (2018) Experimental and thermomechanical study on FSW of PMMA polymer T-joint. Int J Adv Manuf Technol 97:1445–1456. https://doi.org/10.1007/s00170-018-1847-7

Inaniwa S, Kurabe Y, Miyashita Y, Hori H (2013) Applicability of friction stir welding for several plastic materials. Proceedings of 1st international joint symposium on joining and welding. 137–42. https://doi.org/10.1533/978-1-78242-164-1.137

Author information

Authors and Affiliations

Contributions

Conceptualization, investigation, formal analysis and writing original draft were done by RKN. Methodology, validation and data curation were done by VJ. Visualization and writing (review and editing) were done by PM. JDB was supervising the entire work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nath, R.K., Jha, V., Maji, P. et al. A novel double-side welding approach for friction stir welding of polypropylene plate. Int J Adv Manuf Technol 113, 691–703 (2021). https://doi.org/10.1007/s00170-021-06602-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06602-9