Abstract

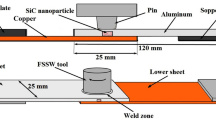

Swing friction stir spot welding (SFSSW) technology which is mainly consisted of two steps is applied to join AA5083 Al alloy to AZ31B Mg alloy in the present investigation. In addition, AA5083/AZ31B joints produced by conventional FSSW were obtained. Optical microscope, scanning electron microscope equipped with energy-dispersive X-ray spectroscope, and X-ray diffraction pattern were used to analyze the morphology and microstructure of different joints. Lap-shear tensile testing and microhardness measurements were conducted to evaluate the joint performance. Results show that the bonding area and the material mixing of the spot welds fabricated by SFSSW technology were both promoted in comparison with that made by conventional FSSW. The thickness of intermetallic compounds (IMCs) at the interface around the filled original keyhole was larger owing to more heat input. The bonding interface of SFSSWed joints was irregular, and the IMCs along the annular interface were thinner than that produced by conventional FSSW. The IMC structure in the interface layer of SFSSWed joints is spherical, which is different from the dendritic structure by conventional FSSW. Finally, IMCs were found in the weld zone through phase analysis by XRD and microhardness measurements of SFSSWed joints. The fracture modes and morphologies were different to two joints, and the lap-shear tensile load of SFSSWed joint was 72.95% larger than the conventional FSSWed joint.

Similar content being viewed by others

Data availability

The manuscript has no associated data or the data will not be deposited.

References

Sivapragash M, Kumaradhas P, Vettivel SC, Retnam BSJ (2018) Optimization of PVD process parameter for coating AZ91D magnesium alloy by Taguchi grey approach. J Magnes Alloy 6(2):171–179

Manladan SM, Yusof F, Ramesh S, Fadzil M, Luo Z, Ao S (2017) A review on resistance spot welding of aluminum alloys. Int J Adv Manuf Technol 90:605–634

Chen YC, Nakata K (2008) Friction stir lap joining aluminum and magnesium alloys. Scr Mater 58:433–436

De Leon M, Shin HS (2016) Material flow behaviors during friction stir spot welding of lightweight alloys using pin and pinless tools. Sci Technol Weld Join 21(2):140–146

Feng M, Luo Z (2019) Interface morphology and microstructure of high-power ultrasonic spot welded Mg/Al dissimilar joint. Sci Technol Weld Join 24(1):63–78

Yan YF, Shen YF, Zhang W, Guan W (2017) Effects of friction stir spot welding parameters on morphology and mechanical property of modified cast nylon 6 joints produced by double-pin tool. Int J Adv Manuf Technol 92:2511–2523

Yan YF, Shen YF, Hou WT, Li JP (2018) Friction stir spot welding thin acrylonitrile butadiene styrene sheets using pinless tool. Int J Adv Manuf Technol 97:2749–2755

Mahto RP, Pal SK (2020) Friction stir welding of dissimilar materials: an investigation of microstructure and nano-indentation study. J Manuf Process 55:103–118

Yazdi SR, Beidokhti B, Haddad-Sabzevar M (2019) Pinless tool for FSSW of AA 6061-T6 aluminum alloy. J Mater Process Technol 267:44–51

Chu Q, Yang XW, Li W, Li Y (2016) Microstructure and mechanical behavior of pinless friction stir spot welded AA2198 joints. Sci Technol Weld Join 21(3):164–170

Li WY, Chu Q, Yang XW, Shen JJ, Vairis A, Wang WB (2018) Microstructure and morphology evolution of probeless friction stir spot welded joints of aluminum alloy. J Mater Process Technol 252:69–80

Chai P, Hu W, Ji SD, Ai XX, Song Q (2019) Refill friction stir spot welding dissimilar Al/Mg alloys. J Mater Eng Perform 28(10):6174–6181

Dong ZB, Song Q, Ai XX, Lv Z (2019) Effect of joining time on intermetallic compound thickness and mechanical properties of refill friction stir spot welded dissimilar Al/Mg alloys. J Manuf Process 42:106–112

Dong ZB, Hu W, Ai XX, Lv Z (2019) Effect of rotation speed on intermetallic compounds and failure load of RFSSW-ed dissimilar Al/Mg. Trans Indian Inst Metals 72(9):2249–2256

Sun YF, Fujii H, Zhu SJ, Guan SK (2019) Flat friction stir spot welding of three 6061-T6 aluminum sheets. J Mater Process Technol 264:414–421

Buffa G, Fratini L, Piacentini M (2007) Tool path design in friction stir spot welding of AA6082-T6 aluminum alloys. Key Eng Mater 344:767–774

Li WY, Li JF, Zhang ZH, Gao DL, Wang WB, Dong CL (2014) Improving mechanical properties of pinless friction stir spot welded joints by eliminating hook defect. Mater Des 62:247–254

Chen YC, Gholinia A, Prangnell PB (2012) Interface structure and bonding in abrasion circle friction stir spot welding: a novel approach for rapid welding aluminum alloy to steel automotive sheet. Mater Chem Phys 134(1):459–463

Mohammadi J, Behnamian Y, Mostafaei A, Lzadi H, Saeid T, Kokabi AH, Gerlich AP (2015) Friction stir welding joint of dissimilar materials between AZ31B magnesium and 6061 aluminum alloys: microstructure studies and mechanical characterizations. Mater Charact 101:189–207

Mohammadi J, Behnamian Y, Mostafaei A, Gerlich AP (2015) Tool geometry, rotation and travel speeds effects on the properties of dissimilar magnesium/aluminum friction stir welded lap joints. Mater Des 75:95–112

Firouzdor V, Kou S (2010) Formation of liquid and Intermetallics in Al-to-Mg friction stir welding. Metall Mater Trans A 41(12):3238–3251

Sato YS, Park SHC, Michiuchi M (2004) Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys. Scr Mater 50(9):1233–1236

Liu ZL, Yang K, Ji SD (2018) Reducing intermetallic compounds of Mg/Al joint in friction stir lap welding. J Mater Eng Perform 27:5605–5612

Panteli A, Robson JD, Brough I, Prangnell PB (2012) The effect of high strain rate deformation on intermetallic reaction during ultrasonic welding aluminum to magnesium. Mater Sci Eng A 556:31–42

Chen K, Liu X, Ni J (2017) Keyhole refilled friction stir spot welding of aluminum alloy to advanced high strength steel. J Mater Process Technol 249:452–462

Sato YS, Shiota A, Kokawa H, Okamoto K, Yang Q, Kim C (2010) Effect of interfacial microstructure on lap shear strength of friction stir spot weld of aluminum alloy to magnesium alloy. Sci Technol Weld Join 15(4):319–324

Shen J, Li Y, Zhang T, Peng D, Wang D, Xu N (2015) Preheating friction stir spot welding of Mg/Al alloys in various lap configurations. Sci Technol Weld Join 20(1):1–10

Fereiduni E, Movahedi M, Kokabi AH (2016) Dissimilar Al/steel friction stir spot welding: to penetrate into the lower steel sheet or not. Sci Technol Weld Join 21(6):466–472

Venkateswaran P, Reynolds AP (2012) Factors affecting the properties of friction stir welds between aluminum and magnesium alloys. Mater Sci Eng A 545:26–37

Tan S, Zheng FY, Chen J, Han JY, Peng LM (2017) Effects of process parameters on microstructure and mechanical properties of friction stir lap linear welded 6061 aluminum alloy to NZ30K magnesium alloy. J Magnes Alloy 5(1):56–63

Chowdhury SH, Chen DL, Bhole SD, Cao X, Wanjara P (2012) Lap shear strength and fatigue life of friction stir spot welded AZ31 magnesium and 5754 aluminum alloys. Mater Sci Eng A 556:500–509

Funding

This is a project funded by the Graduate Innovation Base (Laboratory) Open Fund of Nanjing University of Aeronautics and Astronautics (No. kfjj20190607) and the College Students’ Innovative Entrepreneurial Training Plan Program.

Author information

Authors and Affiliations

Contributions

Siyu Wu: investigation, writing—original draft preparation. Tao Sun: investigation, resources. Yifu Shen: reviewing and editing, supervision. Yinfei Yan: reviewing and editing. Ruiyang Ni: investigation, reviewing and editing. Wenming Liu: reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

This paper is new. Neither the entire paper nor any part of its content has been published or has been accepted elsewhere. It is not being submitted to any other journal as well.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, S., Sun, T., Shen, Y. et al. Conventional and swing friction stir spot welding of aluminum alloy to magnesium alloy. Int J Adv Manuf Technol 116, 2401–2412 (2021). https://doi.org/10.1007/s00170-020-06548-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06548-4