Abstract

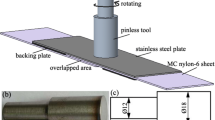

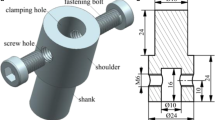

In this paper, pinless tool was utilized in the friction stir spot welding (FSSW) of acrylonitrile butadiene styrene (ABS) sheets. ABS gaskets were added to the through-hole of the clamping plate before FSSW in order to avoid upper sheet thickness reduction. The influence of different combinations of plunge rate (PR) and gasket thickness (GT) on joint morphology and mechanical behavior was investigated. Results showed that low PR and GT caused incomplete connection at the center of the bonded area, and straight and sound bonding interface was formed under the moderate PR and GT. Apparent material flow occurred in the vicinity of the lap interface when PR and GT were large. With the increase of PR and GT, bonded area diameter enlarged while joint fracture load increased first and then slightly decreased. Joints produced with and without thickness reduction failed with different fracture modes, and the removing of upper sheet thickness reduction was beneficial to the promotion of the joint strength.

Similar content being viewed by others

References

Davies G (2003) Future trends in automotive body materials. Mater Automob Bodies 8:252–269

Piccini JM, Svoboda HG (2017) Tool geometry optimization in friction stir spot welding of Al-steel joints. J Manuf Process 26:142–154

Sarkar R, Pal TK, Shome M (2016) Material flow and intermixing during friction stir spot welding of steel. J Mater Process Technol 227:96–109

Bilici MK, Yukler AI (2012) Effects of welding parameters on friction stir spot welding of high density polyethylene sheets. Mater Des 33:545–550

Bilici MK, Yükler Aİ (2012) Influence of tool geometry and process parameters on macrostructure and static strength in friction stir spot welded polyethylene sheets. Mater Des 33:145–152

Bilici MK, Yükler Aİ, Kurtulmuş M (2011) The optimization of welding parameters for friction stir spot welding of high density polyethylene sheets. Mater Des 32:4074–4079

Paoletti A, Lambiase F, Ilio AD (2016) Analysis of forces and temperatures in friction spot stir welding of thermoplastic polymers. Int J Adv Manuf Technol 83(5):1395–1407

Lambiase F, Paoletti A, Ilio AD (2016) Effect of tool geometry on loads developing in friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 87:2293–2303

Lambiase F, Paoletti A, Ilio AD (2016) Friction spot stir welding of polymers: control of plunging force. Int J Adv Manuf Technol 90:2827–2837

Lambiase F, Paoletti A, Ilio AD (2017) Effect of tool geometry on mechanical behavior of friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 88:3005–3016

Lambiase F, Paoletti A, Ilio AD (2015) Mechanical behaviours of friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 80:301–314

Dashatan SH, Azdast T, Ahmadi R, Bagheri A (2013) Friction stir spot welding of dissimilar polymethyl methacrylate and acrylonitrile butadiene styrene sheets. Mater Des 45(6):135–141

Bilici MK (2012) Effect of tool geometry on friction stir spot welding of polypropylene sheets. Express Polym Lett 6(10):805–813

Yan Y, Shen Y, Zhang W, Guan W (2017) Effects of friction stir spot welding parameters on morphology and mechanical property of modified cast nylon 6 joints produced by double-pin tool. Int J Adv Manuf Technol 92:2511–2523

Oliveira PHF, Amancio-Filho ST, Santos JFD, Hage E (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64:2098–2101

Junior WS, Handge UA, Santos JFD, Abetz V, Amancio-Filho ST (2014) Feasibility study of friction spot welding of dissimilar single-lap joint between poly(methyl methacrylate) and poly(methyl methacrylate)-SiO2 nanocomposite. Mater Des 64:246–250

Gonçalves J, Santos JFD, Canto LB, Amancio-Filho ST (2015) Friction spot welding of carbon fiber-reinforced polyamide 66 laminate. Mater Lett 159:506–509

Shin HS, Leon MD (2016) Weldability assessment of friction stir spot welded lightweight alloys using pin and pinless tools. Sci Technol Weld Join 21:99–105

Tozaki Y, Uematsu Y, Tokaji K (2010) A newly developed tool without probe for friction stir spot welding and its performance. J Mater Process Technol 210:844–851

Capone C, Landro LD, Inzoli F, Penco M, Sartore L (2007) Thermal and mechanical degradation during polymer extrusion processing. Polym Eng Sci 47(11):1813–1819

Funding

This study work was supported by the National Natural Science Foundation of China (Grant No. 51475232). This was also a project founded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, Y., Shen, Y., Hou, W. et al. Friction stir spot welding thin acrylonitrile butadiene styrene sheets using pinless tool. Int J Adv Manuf Technol 97, 2749–2755 (2018). https://doi.org/10.1007/s00170-018-2143-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2143-2