Abstract

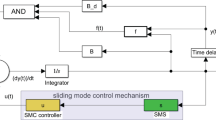

Regenerative chatter is an annoying dynamic phenomenon in machining processes. In this paper, an adaptive sliding mode controller (SMC) is developed for turning chatter mitigation in the presence of control input constraint, parameter uncertainties, and external disturbances. Adaptive laws are employed to estimate parameter uncertainties and disturbances, while a SMC, fulfilling the control input constraint, is designed to mitigate chatter. One unique feature of the developed adaptive approach is that it guarantees chatter suppression even in the presence of control input constraint. Theoretical analyses and experimental investigations are performed, and results demonstrate that the developed SMC with chosen controller parameters guarantees chatter mitigation in the tested examples.

Similar content being viewed by others

Abbreviations

- K f :

-

Cutting coefficient

- F f :

-

Dynamic cutting force

- x(t):

-

Vibration displacement

- m, c, k :

-

Mass, damping, and stiffness, respectively.

- w :

-

Width of cut

- u(t):

-

Control input

- u m :

-

Threshold of control input

- d(t):

-

Generalized uncertainty

- sat():

-

Saturation function

- n :

-

Spindle speed

- k 1 :

-

Upper bound of total disturbance

- ki (i = 2, 3, 4):

-

Positive scalars

- s(t):

-

Sliding function

- s0, c1, p, p1 :

-

Controller parameters

- τ :

-

Time delay

- τ0 :

-

Controller parameter

- ψ :

-

System state vector

- χ():

-

Coefficient function

- λ :

-

Sliding function parameter

- ε :

-

Boundary layer thickness

- β:

-

Lower bound of output capacity

References

Zhang J, Liu CY (2019) Chatter stability prediction of ball-end milling considering multi-mode regenerations. Int J Adv Manuf Technol 100(1-4):131–142

Altintas Y (2000) Manufacturing automation. Cambridge University Press, UK

Munoa J, Beudaert X, Dombovari Z, Altintas Y, Budak E, Brecher C, Stepan G (2016) Chatter suppression techniques in metal cutting. CIRP Ann Manuf Technol 65(2):785–808

Wang CX, Zhang XW, Cao HR, Chen XF, Xiang JW (2018) Milling stability prediction and adaptive chatter suppression considering helix angle and bending. Int J Adv Manuf Technol 95(9-12):3665–3677

Dai YB, Li HK, Hao BT (2018) An improved full-discretization method for chatter stability prediction. Int J Adv Manuf Technol 96(9-12):3503–3510

Baklouti W, Mrad C, Nasri R (2018) Numerical study of the chatter phenomenon in orthogonal turning. Int J Adv Manuf Technol 99(1-4):755–764

Yuan L, Sun SS, Pan ZX, Ding DH, Gienke O, Li WH (2019) Mode coupling chatter suppression for robotic machining using semi-active magnetorheological elastomers absorber. Mech Syst Signal Process 117:221–237

Yang Y, Munoa J, Altintas Y (2010) Optimization of multiple tuned mass dampers to suppress machine tool chatter. Int J Mach Tools Manuf 50(9):834–842

Wang CX, Zhang XW, Liu JX, Cao HR, Chen XF (2019) Adaptive vibration reshaping based milling chatter suppression. Int J Mach Tools Manuf 141:30–35

Clowley A, Boyle A (1970) Active dampers for machine tools. Ann of the CIRP 18(1):213–222

Ganguli A, Deraemaeker A, Preumont A (2007) Regenerative chatter reduction by active damping control. J Sound Vib 300(3-5):847–862

Tewani SG, Rouch KE, Walcott BL (1995) A study of cutting process stability of a boring bar with active dynamic absorber. Int J Mach Tools Manuf 35(1):91–108

Lu XD, Chen F, Altintas Y (2014) Magnetic actuator for active damping of boring bars. CIRP Ann Manuf Technol 63(1):369–372

Huang T, Zhu LJ, Du SL, Chen ZY, Ding H (2018) Robust active chatter control in milling processes with variable pitch cutters. J Manuf Sci Eng Trans ASME 140(10):101005

Ding LY, Sun YX, Xiong ZH (2018) Online chatter suppression in turning by adaptive amplitude modulation of spindle speed variation. J Manuf Sci Eng Trans ASME 140(12):121003

Fallah M, Moetakef-Imani B (2019) Adaptive inverse control of chatter vibrations in internal turning operations. Mech Syst Signal Process 129:91–111

Dohner JL, Lauffer JP, Hinnerichs TD, Shankar N, Regelbrugge M, Kwan CM, Xu R, Winterbauer B, Bridger K (2004) Mitigation of chatter instabilities in milling by active structural control. J Sound Vib 269(1-2):197–211

Moradi H, Movahhedy MR, Vossoughi G (2010) Sliding mode control of machining chatter in the presence of tool wear and parametric uncertainties. J Vib Control 16(2):231–251

Monnin J, Kuster F, Wegener K (2014) Optimal control for chatter mitigation in milling-part 1: modeling and control design. Control Eng Pract 24:156–166

Monnin J, Kuster F, Wegener K (2014) Optimal control for chatter mitigation in milling-part 2: experimental validation. Control Eng Pract 24:167–175

Chen ZY, Zhang HT, Zhang XM, Ding H (2014) Adaptive active chatter control in milling processes. J Dyn Syst Meas Control Trans ASME 136(2):021007

van Dijk NJM, van de Wouw N, Nijmeijer H (2015) Fixed-structure robust controller design for chatter mitigation in high-speed milling. Int J Robust Nonlin 25(17):3495–3514

van Dijk NJM, van de Wouw N, Doppenberg EJ, Oosterling HA, Nijmeijer H (2012) Robust active chatter control in the high-speed milling process. IEEE Trans Control Syst Technol 20(4):901–917

Zhang HT, Wu Y, He DF, Zhao H (2015) Model predictive control to mitigate chatters in milling processes with input constraints. Int J Mach Tools Manuf 91:54–61

Ma HF, Wu JH, Yang LQ, Xiong ZH (2017) Active chatter suppression with displacement-only measurement in turning process. J Sound Vib 401:255–267

Ariaratnam ST, Fofana MS (2002) The effects of nonlinearity in turning operation. J Eng Math 42(2):143–156

Hu QL (2009) Robust adaptive sliding mode attitude maneuvering and vibration damping of three-axis-stabilized flexible spacecraft with actuator saturation limits. Nonlinear Dynam 55(4):301–321

Bartoszewicz A (2015) A new reaching law for sliding mode control of continuous time systems with constraints. Trans Inst Meas Control 37(4):515–521

Krstic M, Kokotovic PV, Kanellakopoulos I (1995) Nonlinear and adaptive control design. Wiley-Interscience, New York

Liang W, Tong H, Li Y, Li BQ, Kong QC (2019) Sliding-mode controller and algorithm for improving servo control of discharge gap in precise fast hole EDM. Int J Adv Manuf Technol 105(5-6):2689–2698

Olgac N, Holm-Hansen BT (1994) A novel active vibration absorption technique: delayed resonator. J Sound Vib 176(1):93–104

Dombovari Z, Wilson RE, Stepan G (2008) Estimates of the bistable region in metal cutting. Proc R Soc A Math Phys Eng Sci 464(2100):3255–3271

Shi HM, Tobias SA (1984) Theory of finite amplitude machine tool instability. Int J Mach Tool Des Res 24(1):45–69

Park G, Bement MT, Hartman DA, Smith RE, Farrar CR (2007) The use of active materials for machining processes: a review. Int J Mach Tools Manuf 47(15):2189–2206

Wu D, Chen K (2010) Chatter suppression in fast tool servo-assisted turning by spindle speed variation. Int J Mach Tools Manuf 50(12):1038–1047

Choudhury SK, Goudimenko NN, Kudinov VA (1997) On-line control of machine tool vibration in turning. Int J Mach Tools Manuf 37(6):801–811

Shi F, Cao HR, Zhang XW, Chen XF (2019) A chatter mitigation technique in milling based on H∞-ADDPMS and piezoelectric stack actuators. Int J Adv Manuf Technol 101(9-12):2233–2248

Pan JC, Su CY (2001) Chatter suppression with adaptive control in turning metal via application of piezoactuator. Proceedings of the 40th IEEE Conference on Decision and Control, pp. 2436-2441

Matsubara T, Yamamoto H, Mizumoto H (1989) Chatter suppression by using piezoelectric active damper. ASME Des Eng Div Publ DE 18:79–83

Zhu WH, Jun MB, Altintas Y (2001) A fast tool servo design for precision turning of shafts on conventional CNC lathes. Int J Mach Tools Manuf 41(7):953–965

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, H., Wu, J. & Xiong, Z. Active chatter control in turning processes with input constraint. Int J Adv Manuf Technol 108, 3737–3751 (2020). https://doi.org/10.1007/s00170-020-05475-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05475-8