Abstract

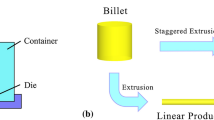

Traditional bending products are usually divided into two steps: extrusion and bending. Staggered extrusion (SE) as a new process was proposed to prepare Mg alloy bending products in this paper. By designing the structure at one end of the stem, the dual functions of extrusion process and bending process can be realized in a single extrusion pass. The results of the present study show that by adjusting the degree of deformation of the AZ31 Mg alloy, a bending product with a specific curvature could be obtained by the SE process, and the microstructure of the bending product was refined. When the extrusion ratio was increased from 11.11 to 44.44, the grain size was refined from 23.89 to 9.69 μm, and the percentage of recrystallized structures increased from 61.1 to 78.8%.

Similar content being viewed by others

References

Chen G, Zhang S, Zhang H, Han F, Wang G, Chen Q, Zhao Z (2018) Controlling liquid segregation of semi-solid AZ80 magnesium alloy by back pressure thixoextruding. Journal of Materials Processing Technology 259:88–95

Xing J, Hiroshi YX, Miura H, Sakai T (2005) Ultra-fine grain development in an AZ31 magnesium alloy during multi-directional forging under decreasing temperature conditions. Materials Transactions 46(7):1646–1650

Li F, Liu Y, Li XB (2017) Microstructure evolution and deformation behavior of AZ31 magnesium alloy during alternate forward extrusion. Acta Metallurgica Sinica (English Letters) 30(11):1135–1144

Härtel S, Graf M, Lehmann T, Ullmannc M (2017) Influence of tension-compression anomaly during bending of magnesium alloy AZ31. Materials Science & Engineering A 705:62–71

McQueen HJ, Imbert CAC (2004) Dynamic recrystallization: plasticity enhancing structural development. Journal of Alloys and Compounds 378(1-2):35–43

Jain A, Duygulu O, Brown DW, Tome CN, Agnew SR (2008) Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy, AZ31B, sheet. Materials Science & Engineering: A (Structural Materials: Properties, Microstructure and Processing) 486(1-2):545–555

Yamashita A, Horita Z, Langdon TG (2001) Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Materials Science & Engineering A (Structural Materials, Properties, Microstructure and Processing) 300(1-2):142–147

Yi SB, Zaefferer S, Brokmeier HG (2006) Mechanical behaviour and microstructural evolution of magnesium alloy AZ31 in tension at different temperatures. Materials Science and Engineering: A 424(1-2):275–281

Helis L, Okayasu K, Fukutomi H (2006) Microstructure evolution and texture development during high-temperature uniaxial compression of magnesium alloy AZ31. Materials Science & Engineering A (Structural Materials, Properties, Microstructure and Processing) 430(1-2):98–103

Fukuda H, Szpunar JA, Kondoh K, Chromik R (2010) The influence of carbon nanotubes on the corrosion behaviour of AZ31B magnesium alloy. Corrosion Science 52(12):3917–3923

Ding H, Liu L, Kamado S, Ding W, Kojima Y (2008) Study of the microstructure, texture and tensile properties of as-extruded AZ91 magnesium alloy. Journal of Alloys and Compounds 456(1-2):400–406

Mukai T, Yamanoi M, Watanabe H, Higashi K (2001) Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure. Scripta Materialia 45(1):89–94

Ion SE, Humphreys FJ, White SH (1982) Dynamic recrystallization and the development of microstructure during the high temperature deformation of magnesium. Acta Metallurgica 30(10):1909–1919

Spigarelli S, ElMehtedi M, Cabibbo M, Evangelista E, Kaneko J, Jäger A, Gartnerova V (2007) Analysis of high-temperature deformation and microstructure of an AZ31 magnesium alloy. Materials Science & Engineering A (Structural Materials, Properties, Microstructure and Processing) 462(1-2):197–201

Zhong F, Wu H, Jiao Y, Wu R, Zhang J, Hou L, Zhang M (2020) Effect of Y and Ce on the microstructure, mechanical properties and anisotropy of as-rolled Mg-8Li-1Al alloy. Journal of Materials Science & Technology 39:124–134

Valle JAD, Ruano OA (2008) Influence of texture on dynamic recrystallization and deformation mechanisms in rolled or ECAPed AZ31 magnesium alloy. Materials Science & Engineering: A (Structural Materials: Properties, Microstructure and Processing) 487(1-2):473–480

Beer AG, Productnett MR (2008) Microstructural development during hot working of Mg-3Al-1Zn. Metallurgical & Materials Transactions A 38(8):1856–1867

Gall S, Müller S, Reimers W (2013) Microstructure and mechanical properties of magnesium AZ31 sheets produced by extrusion. International Journal of Material Forming 6(1):187–197

Hu HJ, Wang H, Zhai ZY, Li YY, Fan JZ, Ou ZW (2015) Effects of channel angles on extrusion-shear for AZ31 magnesium alloy: modeling and experiments. The International Journal of Advanced Manufacturing Technology 76(9-12):1621–1630

Kuo CC, Lin BT (2012) Optimization of springback for AZ31 magnesium alloy sheets in the L-bending process based on the Taguchi method. International Journal of Advanced Manufacturing Technology 58(1-4):161–173

Nguyen DT, Yang SH, Jung DW, Banh TL, Kim YS (2012) A study on material modeling to predict spring-back in V-bending of AZ31 magnesium alloy sheet at various temperatures. International Journal of Advanced Manufacturing Technology 62(5-8):551–562

Wang YP, Li F, Shi WY, Li XW, Fang W B (2019) Microstructure, bending behavior and texture evolution of AZ31B magnesium alloy bending products processed by staggered extrusion (SE). Materials Characterization, 155. 10.1016/j.matchar.2019.109842

Wang Y, Li F, Li XW, Fang WB (2020) Unusual texture formation and mechanical property in AZ31 magnesium alloy sheets processed by CVCDE. Journal of Materials Processing Technology 275 10.1016/j.jmatprotec.2019.116360

Li F, Zeng X, Cao GJ (2015) Investigation of microstructure characteristics of the CVCDEed AZ31 magnesium alloy. Materials Science & Engineering A 639:395–401

Hu H, Qin X, Zhang D, Ma X (2018) A novel severe plastic deformation method for manufacturing AZ31 magnesium alloy tube. Journal of Advanced Manufacturing Technology 98(1-4):897–903

Funding

This work was supported by the National Natural Science Foundation of China (51975166) and the Fundamental Research Foundation for Universities of Heilongjiang Province (LGYC2018JQ011) and the Natural Science Foundation of Heilongjiang Province (LH2019E056).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y.P., Li, F. & Li, X.W. Effect of extrusion ratio (λ) on dynamic recrystallization of AZ31 magnesium alloy bending products prepared by staggered extrusion (SE). Int J Adv Manuf Technol 108, 289–297 (2020). https://doi.org/10.1007/s00170-020-05416-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05416-5