Abstract

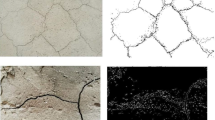

The internal crack defect is prone to appear in the inner part of casting products during the production process due to the influence of casting craft and on-site environment. In order to ensure the internal quality of the casting products, nondestructive examination and defect detection technology should be used to detect the internal crack of the casting product. The existing defect detection technologies have some problems such as poor generalization and low accuracy. Therefore, an internal crack defect detection method based on the Relief algorithm and Adaboost-SVM is proposed in this paper. Firstly, casting image is preprocessed by grayscale transformation, bilateral filtering, and adaptive image segmentation. Secondly, HOG feature, invariant moment feature, and LBP feature are extracted, and sensitive feature set is selected by Relief algorithm. Finally, the Adaboost-SVM is used to construct the internal crack detection model to realize the crack detection with high generalization and accuracy. The effectiveness of the method is verified by the casting image dataset collected in the actual industrial field. The experimental result reveals that the proposed method could not only extract sensitive feature set but also has better classification performance and generalization ability than other common classifiers.

Similar content being viewed by others

References

Rajkolhe R, Khan J (2014) Defects, causes and their remedies in casting process: a review. IJRAT 2(3):375–383

Lovejoy M (2012) Magnetic particle inspection: a practical guide. Springer Science & Business Media

Duan F, Yin S, Song P, Zhang W, Zhu C, Yokoi H (2019) Automatic welding defect detection of X-ray images by using cascade Adaboost with penalty term. IEEE ACCESS 7:125929–125938

Ghorai S, Mukherjee A, Gangadaran M, Dutta PK (2013) Automatic defect detection on hot-rolled flat steel products. IEEE T INSTRUM MEAS 62(3):612–621

Beyerer J, Puente Len F (2015) Automated visual inspection and machine vision. Automated Visual Inspection and Machine Vision 9530

Mery D, Arteta C (2017) Automatic defect recognition in X-ray testing using computer vision. IEEE Winter Conference on Applications of Computer Vision, pp 1026–1035

Du W, Shen H, Fu J, Zhang G, He Q (2019) Approaches for improvement of the X-ray image defect detection of automobile casting aluminum parts based on deep learning. NDT & E INT 107:102144

Zhao X, He Z, Zhang S, Liang D (2015) A sparse-representation-based robust inspection system for hidden defects classification in casting components. NEUROCOMPUTING 153:1–10

Shengqian W, Yuanhua Z, Daowen Z (2002) Adaptive shrinkage de-noising using neighbourhood characteristic. Electron Lett 38(11):502–503

Bhutada G, Anand R, Saxena S (2011) Edge preserved image enhancement using adaptive fusion of images denoised by wavelet and curvelet transform. Digit Signal Process 21(1):118–130

Bhattacharyya S, Maulik U, Dutta P (2011) Multilevel image segmentation with adaptive image context based thresholding. Appl Soft Comput 11(1):946–962

Vantaram SR, Saber E, Dianat SA, Shaw MQ, Bhaskar R (2010) Multiresolution adaptive and progressive gradient-based color-image segmentation. J Electron Imaging 19(1):013001

Tsai D-M, Lin C-P, Huang K-T (2005) Defect detection in coloured texture surfaces using Gabor filters. Imaging Sci J 53(1):27–37

Luiz AM, Flávio LP, Paulo EA (2010) Automatic detection of surface defects on rolled steel using computer vision and artificial neural networks. IECON 2010-36th Annual Conference on IEEE Industrial Electronics Society, pp 1081–1086

Shumin D, Zhoufeng L, Chunlei L (2011) Adaboost learning for fabric defect detection based on hog and SVM. International conference on multimedia technology, pp 2903-2906

Amid E, Aghdam SR, Amindavar H (2012) Enhanced performance for support vector machines as multi-class classifiers in steel surface defect detection. World Acad Sci Eng Technol 6(7):1096–1100

Da Silva RR, Siqueira MH, Calôba LP, Da Silva IC, De Carvalho A, Rebello J (2002) Contribution to the development of a radiographic inspection automated system. Russ J Nondestruct+ 7(12):1–8

Shao J, Shi H, Du D, Wang L, Cao H (2011) Automatic weld defect detection in real-time X-ray images based on support vector machine. 4th International Congress on Image and Signal [rocessing, pp 1842-1846

Martínez SS, Vázquez CO, García JG, Ortega JG (2017) Quality inspection of machined metal parts using an image fusion technique. MEASUREMENT 111:374–383

Boaretto N, Centeno TM (2017) Automated detection of welding defects in pipelines from radiographic images DWDI. NDT & E INT 86:7–13

Niu Z, Li H (2019) Research and analysis of threshold segmentation algorithms in image processing. Journal of Physics: Conference Series, pp 022122

Dalal N, Triggs B (2005) Histograms of oriented gradients for human detection. In: Schmid C, Soatto S, Tomasi C (eds) 2005 IEEE computer society conference on computer vision and pattern recognition, Vol 1, Proceedings. Proceedings - Ieee Computer Society Conference on Computer Vision And Pattern Recognition. Ieee Computer Soc, Los Alamitos, pp 886–893

Zhu Q, Yeh M-C, Cheng K-T, Avidan S (2006) Fast human detection using a cascade of histograms of oriented gradients. IEEE computer society conference on computer vision and pattern recognition (CVPR'06), pp 1491-1498

Zhao G, Ahonen T, Matas J, Pietikainen M (2011) Rotation-invariant image and video description with local binary pattern features. IEEE T Image Process 21(4):1465–1477

Savithiri G, Murugan A (2011) Performance analysis on half iris feature extraction using GW, LBP and HOG. IJCA 22(2):27–32

Kira K, Rendell LA (1992) A practical approach to feature selection. Machine Learning Proceedings, pp 249-256

Demetgul M (2013) Fault diagnosis on production systems with support vector machine and decision trees algorithms. Int J Adv Manuf Tech 67(9–12):2183–2194

Freund Y, Schapire R, Abe N (1999) A short introduction to boosting. Journal-Japanese Society For Artificial Intelligence 14(771–780):1612

Meir R, Rätsch G (2003) An introduction to boosting and leveraging. Advanced lectures on machine learning, pp 118-183

Kohavi R (1995) A study of cross-validation and bootstrap for accuracy estimation and model selection. Ijcai 14(2):1137–1145

Gong R, Wu C, Chu M, Liu X (2016) The strip steel surface defect recognition based on multiple support vector hyper-sphere with feature and sample weights. Steel Res Int 87(12):1678–1685

Funding

This research was supported by the National Natural Science Foundation of China (Grant No. 51875432).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jin, C., Kong, X., Chang, J. et al. Internal crack detection of castings: a study based on relief algorithm and Adaboost-SVM. Int J Adv Manuf Technol 108, 3313–3322 (2020). https://doi.org/10.1007/s00170-020-05368-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05368-w