Abstract

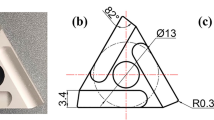

Process-induced damages, such as burrs and delamination, frequently occur and are the critical hole quality issues for CFRPs. These damages are strongly influenced by the axial cutting force. By employing the novel drill-milling process, the influence of the axial cutting force may be completely eliminated, and the process-induced damages can be remarkably removed. The drill-milling tools with a better performance are very critical to the drill-milling process. In this paper, according to the drill structure with V-shaped cutting edges and the mill structure with double-crossed helix flutes, two different new drill-milling tools are designed, and a series of tests are conducted on CFRPs. The result indicates that the influences of the cutting forces on the damages can be remarkably reduced during the helical milling phase by employing the drill-milling process. Under the same cutting conditions, the cutting forces of T2 are significant less than that of T1. The re-trimming effect of T2 is superior significant than that of T1 during the helical milling phase. The damages can be significantly reduced by using these two tools, especially by using T2 tool.

Similar content being viewed by others

References

Abena A, Essa K (2019) 3D micro-mechanical modeling of orthogonal cutting of UD-CFRP using smoothed particle hydrodynamics and finite element methods. Compos Struct 218:174–192

Su YL (2019) Effect of the cutting speed on the cutting mechanism in machining CFRP. Compos Struct 220:662–676

Cheng H, Gao JY, Kafka OL, Zhang KF, Luo B (2017) A micro-scale cutting model for UD CFRP composites with thermo-mechanical coupling. Compos Sci Technol 153:18–31

Feito N, Díaz-álvarez J, Lopez-Puente J, Miguelez MH (2018) Experimental and numerical analysis of step drill bit performance when drilling woven CFRPs. Compos Struct 184:1147–1155

Deng H, Xu Z (2019) Dressing methods of superabrasive grinding wheels: a review. J Manuf Process 45:46–69

Jia Z, Fu R, Niu B, Qian B, Bai Y (2016) Novel drill structure for damage reduction in drilling CFRP composites. Int J Mach Tools Manuf 110:55–65

Çelik A, Lazoglu I, Kara A, Kara F (2015) Investigation on the performance of SiAlON ceramic drills on aerospace grade CFRP composites. J Mater Process Technol 223:39–47

Yu Z, Li CP, Kurniawan R, Park KM, Ko YJ (2019) Drill bit with a helical groove edge for clean drilling of carbon fiber-reinforced plastic. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2019.116291

Su F, Zheng L, Sun FJ, Wang ZH, Deng ZH, Qiu XY (2018) Novel drill bit based on the step-control scheme for reducing the CFRP delamination. J Mater Process Technol 262:157–167

Su F, Deng ZH, Sun FJ, Li SC, Wu QP, Jiang XJ (2019) Comparative analyses of damages formation mechanisms for novel drills based on a new drill-induced damages analytical model. J Mater Process Technol 271:111–125

Tian J, Wu F, Zhang P, Lin B, Liu T, Liu L (2019) The coupling effect and damage analysis when drilling GFRP laminates using candlestick drills. Int J Adv Manuf Technol 102:519–531

Wang JJ, Zhang JF, Feng PF, Guo P (2018) Damage formation and suppression in rotary ultrasonic machining of hard and brittle materials: a critical review. Ceram Int 44:1227–1239

Caggiano A, Improta I, Nele L (2018) Characterization of a new dry drill-milling process of carbon fibre reinforced polymer laminates [J]. Mater 11(8):1–15

Wang GD, Melly SK, Li N, Peng T, Li YC (2018) Research on milling strategies to reduce delamination damage during machining of holes in CFRP/Ti stack. Compos Struct 200:679–688

Wang GD, Suntoo D, Li N, Peng T, Li YC (2018) Experimental research in CFRP/Ti stack through different helical milling strategies. Int J Mach Tools Manuf 98:3251–3267

Ahmad N, Khan SA, Raza SF (2019) Influence of hole diameter, workpiece thickness, and tool surface condition on machinability of CFRP composites in orbital drilling: a case of workpiece rotation. Int J Mach Tools Manuf 103:2007–2015

Amini S, Baraheni M, Hakimi E (2019) Enhancing dimensional accuracy and surface integrity by helical milling of carbon fiber reinforced polymers. Int J Lightweight Mater Manuf. https://doi.org/10.1016/j.ijlmm.2019.03.001

Rahim EA, Mohid Z, Hamzah MR, Yusuf AF, Rahman NA (2014) Performance of tools design when helical milling on carbon fiber reinforced plastics (CFRP) aluminum (Al) stack. Appl Mech Mater 465-466:1075–1079

Li SP, Qin XD, Jin Y, Sun D, Li YH (2018) A comparative study of hole-making performance by coated and uncoated WC/Co cutters in helical milling of Ti/CFRP stacks. Int J Adv Manuf Technol 94:2645–2658

Boccarusso L, Fazio DD, Durante M, Langella A, Fabrizio MCM (2019) CFRPs drilling: comparison among holes produced by different drilling strategies. Procedia CIRP 79:325–330

Durante M, Boccarusso L, De Fazio D, Dario Langella A (2019) Circular cutting strategy for drilling of carbon fiber-reinforced plastics (CFRPs). Mater Manuf Process 34(5):554–566

Chegdani F, Mansori ME (2019) Tribo-functional effects of double-crossed helix on surface finish, cutting friction and tool wear mechanisms during the milling process of natural fiber composites. Wear 426-427:1507–1514

Chen T, Xiang JP, Gao F, Liu XL, Liu GJ (2019) Study on cutting performance of diamond-coated rhombic milling cutter in machining carbon fiber composites. Int J Adv Manuf Technol 103:4731–4737

Funding

Special thanks to the National Science Foundation of China (No. 51805164) for funding this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

“This is an original paper which has neither previously, nor simultaneously, in whole or in part been submitted anywhere else.”

Rights and permissions

About this article

Cite this article

Su, F., Hu, Z., Rong, Z. et al. New drill-milling tools for novel drill-milling process of carbon fiber-reinforced plastics. Int J Adv Manuf Technol 107, 217–228 (2020). https://doi.org/10.1007/s00170-020-05092-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05092-5