Abstract

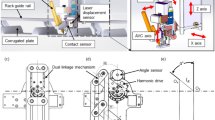

Sphere-pipe joints welding is widely used in industrial applications. This paper presents a robot welding approach for the sphere-pipe joints with swing and multi-layer planning. Firstly, various coordinate systems are used to describe the geometric relationship between weld seam and robot welding torch. The sphere-pipe intersecting curve welding process is basically uphill and downhill welding. Therefore, this paper establishes a description model of the welding torch attitude, which parameterizes the attitude description and automatically adjusts the torch attitude during the welding process according to the change of weld inclination angle. To overcome the negative effects of gravity, such as deepening of the molten pool and reduction of the weld width, this paper integrates the swing welding technology into trajectory planning and gives a solving algorithm for the welding torch swing curve. The swing welding also can reduce the number of weld pass. Therefore, multi-layer single-pass swing welding is an economical and efficient way for thicker weldments. In this paper, a multi-layer single-pass swing welding planning algorithm is proposed, which can automatically determine the height and swing amplitude of each welding layer. Finally, the industrial robot Puma560 is used to carry out experimental simulation, and the simulation results are used to verify the feasibility and accuracy of this approach.

Similar content being viewed by others

References

Xu F (2014) Concise manual for welding process 2rd. Shanghai Science and Technology Press, Shanghai

Sharma V, Shahi AS (2014) Effect of groove design on mechanical and metallurgical properties of quenched and tempered low alloy abrasion resistant steel welded joints. Mater Des 53:727–736

Yan L, Ya L, Xincheng T (2019) Trajectory and velocity planning of the robot for sphere-pipe intersection hole cutting with single-Y welding groove. Robot Comput Integr Manuf 56:244–253

Wang QH, Yin GF, Xu L, He SS (2012) Mathematical model and simulation for cutting of pipe tee with root face groove. Trans China Weld Instit 33(3):77–80

Kavraki L, Svestka P, Latombe JC, Overmars M (1996) Probabilistic roadmaps for path planning in high-dimensional configuration space. IEEE Trans Robot Autom 12(4):566–580

Barraquand J, Kavraki L, Latombe JC, Li TY, Motwani R, Raghavan P (1997) A random sampling scheme for path planning. Int J Robot Res 16(6):759–774

Zou Q, Guo W, Hamimid FY (2017) A novel robot trajectory planning algorithm based on NURBS velocity adaptive interpolation. International conference on mechanical design 1191–1208

Fang HC, Ong SK, Nee AYC (2017) Adaptive pass planning and optimization for robotic welding of complex joints. Adv Manuf 5(2):93–104

Dharmawan A, Sedore B, Soh G, Foong S, Otto K Robot base placement and kinematic evaluation of 6r serial manipulators to achieve collision-free welding of large intersecting cylindrical pipes. International design engineering technical conferences and computers and information in engineering conference, Volume 5C:39th Mechanisms and Robotics Conference

Zhang C, Li H, Jin Z, Gao H (2017) Seam sensing of multi-layer and multi-pass welding based on grid structured laser. Int J Adv Manuf Technol 91(1-4):1103–1110

Shi L, Tian XC (2014) Automation of main pipe-rotating welding scheme for intersecting pipes. Int J Adv Manuf Technol 77(5-8):955–964

Shi L, Tian XC, Zhang CH (2015) Automatic programming for industrial robot to weld intersecting pipes. Int J Adv Manuf Technol 81(9-12):2099–2107

Bahrami-Samani M, Agahi M, Moosavian SA (2007) Design and analysis of a welding robot. IEEE International Conference on Automation Science and Engineering pp 454–459

Fang HC, Ong SK, Nee AYC (2017) Robot path planning optimization for welding complex joints. Int J Adv Manuf Technol 90:3829–3839

Liu J, Hu S, Junqi S, Tuo Y, Changliang C (2017) Intersection seam of sphere and tube welding robot trajectory optimization based on spatial offset curve. Trans China Weld Instit 38(11):47–50

Zhao J, Hu S, Junqi S, Changliang C, Wei D (2011) Mathematical model based on MATLAB for intersection seam of sphere and tube. Trans China Weld Instit 32(8):89–92

Changliang C, Hu S, He D, Junqi S (2013) An approach to the path planning of tube-sphere intersection welds with the robot dedicated to j-groove joints. Robot Comput Integr Manuf 29(4):41–48

Mitsi S, Bouzakis KD, Mansour G, Sagris D, Maliaris G (2005) Off-line programming of an industrial robot for manufacturing. Int J Adv Manuf Technol 26(3):262–267

Kucuk S (2016) Maximal dexterous trajectory generation and cubic spline optimization for fully planar parallel manipulators. Comput Electr Eng 56:634–647

Kucuk S (2017) Optimal trajectory generation algorithm for serial and parallel manipulators. Robot Comput Integr Manuf 48:219–232

Yu JP, Shi P (2015) Approximation-based discrete-time adaptive position tracking control for interior permanent magnet synchronous motors. IEEE Trans Cybern 45(7):1363–1371

Craig JJ (2003) Introduction to Robotics: mechanics and control, 3rd edn. Prentice Hall, London

Siciliano B, Sciavicco L, Villani L, Oriolo G (2008) Robotics: Modelling, planning, and control

Hongzhu G, Jinggeng W, Fu R (2007) Space analytic geometry. Beijing Normal University Press, Beijing

Spong MW, Hutchinson S, Vidyasagar M (2016) Robot modeling and control

Funding

The authors gratefully thank the research funding by the National Key Research and Development Plan of China under Grant No. 2017YFB13035.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Ren, L. & Tian, X. A robot welding approach for the sphere-pipe joints with swing and multi-layer planning. Int J Adv Manuf Technol 105, 265–278 (2019). https://doi.org/10.1007/s00170-019-04216-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04216-w