Abstract

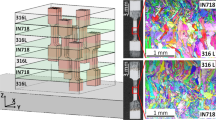

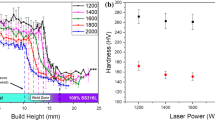

This work examines a functionally graded material, fabricated using laser-directed deposition and synchronous preheating, that grades from 316L stainless steel to Ti6Al4V through a transition of Inconel625. The cracking behavior, microstructure evolution, and microhardness were determined as a function of position within the graded materials. The results showed that cracks occurred in the 316L/Inconel625- and Inconel625/Ti6Al4V-graded specimen with no preheating, defined as a solidification crack and cold crack, respectively. Precipitations of Mo-enriched eutectic phase were experimentally identified to be the major cause of the cracking. The precipitated phases of prepared gradient materials were fine and uniform by laser synchronous preheating, and no cracks were found. The hardness reached the maximum value in 70% Inconel625 + 30% Ti6Al4V. Work shows that the key to fabricating 316L/Inconel625/Ti6Al4V gradient material by laser deposition is to reduce the formation of Cr and Mo enrichment phase and the uneven temperature tendency.

Similar content being viewed by others

References

Singh BM, Rokne J, Dhaliwal RS (2008) Vibrations of a solid sphere or shell of functionally graded materials. Eur J Mech A-Solid 27(3):460–468

Borkar T, Conteri R, Chen X, Ramanujan RV, Banerjee R (2016) Laser additive processing of functionally graded Fe-Si-B-Cu-Nb soft magnetic materials. Mater Manuf Process. 29:175–181

Abioye TE, Farayibi PK, Kinnel P, Clare AT (2015) Functionally graded Ni-Ti microstructures synthesised in process by direct laser metal deposition. Int. J. Adv Manuf Tech 79(5–8):1–8

Gupta A, Talha M (2015) Recent development in modeling and analysis of functionally graded materials and structures. Prog Aerosp Sci 79:1–14

Hosseini HS, Shamanian M, Kermanpur A (2016) Microstructural and weldability analysis of Inconel617/AISI 310 stainless steel dissimilar welds. Int J Pres Ves Pip 144:18–24

Mvola B, Kah P, Martikainen J, Suoranta R (2016) Dissimilar welded joints operating in subzero temperature environment. Int J Adv Manuf Tech 87(9–12):1–17

Kamachi Mudali U, Ananda Rao BM, Shanmugam K, Natarajan R, Raj B (2003) Corrosion and microstructural aspects of dissimilar joints of titanium and type 304L stainless steel. J Nucl Mater 321:40–48

Pardal G, Ganguly S, Williams S, Vaja J (2016) Dissimilar metal joining of stainless steel and titanium using copper as transition metal. Int. J Adv Manuf Tech 86(5–8):1139–1150

Kundu S, Sam S, Chatterjee S (2011) Evaluation of interface microstructure and mechanical properties of the diffusion bonded joints of Ti-6AI-4V alloy to micro-duplex stainless steel. Mater Sci Eng A 528:4910–4916

Ghosh M, Chatterjee S (2003) Diffusion bonded transition joints of titanium to stainless steel with improved properties. Mater Sci Eng A 358:152–158

Dey HC, Ashfaq M, Bhaduri AK, Rao KP (2009) Joining of titanium to 304L stainless steel by friction welding. J Mater Process Technol 209:5862–5870

Amine T, Newkirk JW, Liou F (2014) An investigation of the effect of laser deposition parameters on characteristics of multilayered 316. Int J Adv Manuf Tech 73(9–12):1739–1749

Abioye TE, Medrano-Tellez A, Farayibi PK, Oke PKM (2017) Laser metal deposition of multi-track walls of 308LSi stainless steel. Mater Manuf Process 32:1660–1666

Bobbio LD, Otis RA, Borgonia JP, Dillon RP, Shapiro AA, Liu ZK, Beese AM (2017) Additive manufacturing of a functionally graded material from Ti-6Al-4V to Invar: experimental characterization and thermodynamic calculations. Acta Mater 127:133–142

Mahamood RM, Akinlabi ET (2015) Laser metal deposition of functionally graded Ti6Al4V/TiC. Mater Des 84:402–410

Liang YJ, Liu D, Wang HM (2014) Microstructure and mechanical behavior of commercial purity Ti/Ti6Al2Zr1Mo1V structurally graded material fabricated by laser additive manufacturing. Scr Mater 74:80–83

Koike R, Unotoro I, Kakinuma Y, Aoyama T, Oda Y, Kuriya T, Fujishima M (2014) Evaluation for mechanical characteristics of Incone1625-SUS316L joint produced with direct energy deposition. Procedia Manuf 14:105–110

Xue W, Bose S, Bandyopadhyay A, Krishna BV (2008) Functionally graded CoCrMo coating on Ti6Al4V alloy structures. Acta Biomater 4:697–706

Carroll BE, Otis RA, Borgonia JP, Suh J, Dillon RP, Shapiro AA, Hofmann DC, Beese AM (2016) Functionally graded material of 304L stainless steel and Inconel 625 fabricated by directed energy deposition: characterization and thermodynamic modeling. Acta Mater 108:46–54

Reichardt A, Dillon RP, Borgonia JP, Shapiro AA, Hosemann P (2016) Development and characterization of Ti-6Al-4V to 304L stainless steel gradient components fabricated with laser deposition additive manufacturing. Mater Des 104:404–413

Fotovvati B, Wayne SF, Lewis G, Asadi E (2018) A review on melt-pool characteristics in laser welding of metals. Adv in Mater Sci Eng 11:1–18

Fotovvati B, Namdari N, Dehghanghadikolaei A (2018) Fatigue performance of selective laser melted Ti6Al4V components: state of the art. Mater Res Express 6(1):012002

Chen HC, Pinkerton AJ, Li L (2011) Fiber laser welding of dissimilar alloys of Ti-6Al-4V and Inconel 718 for aerospace applications. Int J Adv Manuf Tech 52(9–12):977–987

Cherry JA, Davies HM, Mehmood S, Lavery NP, Brown SGR, Sienz J (2015) Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Tech 76(5–8):869–879

Demir AG, Previtali B (2017) Multi-material selective laser melting of Fe/Al-12Si components. Manuf Let 11:8–11

Wei C, Sun Z, Huang Y, Li L (2018) Embedding anti-counterfeiting features in metallic components via multiple material additive manufacturing. Addit Manuf 24:1–12

Zhai Y, Huang B, Zhang Z, Mao X, Zhao Z (2018) Effect of preheating on welding cold crack sensitivity of China low activation martensitic steel. Fusion Eng Des 133:32–38

Shah K, Haq I, Khan A, Shah SA, Pinkerton AJ (2014) Parametric study of development of Inconel-steel functionally graded materials by laser direct metal deposition. Mater Des 54:531–538

Wei S, Zhang ZH, Shen XB, Wang FC, Lee SK (2012) Simulation of temperature and stress distributions in functionally graded materials synthesized by a spark plasma sintering process. Comp Mater Sci 60(5):168–175

Lin YC, Lee KH (1997) Effect of preheating on the residual stress in type 304 stainless steel weldment. J Mater Process Tech 63(1–3):797–801

Shalvandi M, Hojjat Y, Abdullah A, Asadi H (2013) Influence of ultrasonic stress relief on stainless steel 316 specimens: a comparison with thermal stress relief. Mater Des 46(4):713–723

Funding

This work was supported by the Natural Science Fund of Anhui Province Education Office No. KJ 2018A0063 and the National Science Foundation of China under Grant Nos. 51505271 and 51375015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meng, W., Zhang, W., Zhang, W. et al. Additive fabrication of 316L/Inconel625/Ti6Al4V functionally graded materials by laser synchronous preheating. Int J Adv Manuf Technol 104, 2525–2538 (2019). https://doi.org/10.1007/s00170-019-04061-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04061-x