Abstract

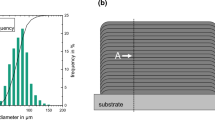

A potential problem in applying the direct laser deposition (DLD) technique to material fabrication is the effect that subsequent deposited layers have on reheating previous laser deposition layers. Most of the previous investigations examined the effect of the laser deposition parameters on the microstructure and mechanical properties of a single layer. This work focused on the effect of the laser parameters of subsequent layers on the microstructure and mechanical properties of the deposited layers to select proper parameters and characterize the effect. The microstructure morphology and property values are affected by the varied parameters. This leads to some tempering and aging effects in the steels. The microstructure of the top layer was equiaxed, while the near substrate region was fine dendritic. Typically, both of the travel speed and power of the laser show the significant effects on microstructure and hardness.

Similar content being viewed by others

References

Kell J, Tyrer JR, Higginson RL, Thomson RC (2005) Microstructural characterization of autogenous laser welds on 316L stainless steel using EBSD and EDS. J Microsc 217:167–173

Qin Y, Juster NP (2003) Advances in manufacturing technology XVII (1st Edition) p 132

Zhang K, Zhang X, Liu W (2012) Influences of processing parameters on dilution ratio of laser cladding layer during laser metal deposition shaping. Adv Mater Res 549:785–789

Wu X, Liang J, Mei J, Mitchell C, Goodwin PS, Voice W (2004) Microstructures of laser-deposited Ti–6Al–4V. Mater Des 25:137–144

Mahamood RM, Akinlabi ET, Shukla M, Pityana S (2013) Scanning velocity influence on microstructure, microhardness and wear resistance performance of laser deposited Ti6Al4V/TiC composite. Mater Des 50:656–666

Amine T, Sparks TE, Liou F (2011) A strategy for fabricating complex structures via a hybrid manufacturing process. Solid Freeform Fabrication Symposium, Proceedings of the Twenty Third Annual Solid Freeform Fabrication Symposium, Austin

Kattamis TZ, Coughlin JC, Flemings MC (1967) Trans Metall Soc TMS-AIME 239:1504

Dutta Majumdar J, Li L (2009) Studies on direct laser cladding of SiC dispersed AISI 316L stainless steel. Metallurgical and materials transactions. A, Phys Metall Mater Sci 40(12):3001–3008

Boisselier D, Sankaré S (2012) Influence of powder characteristics in laser direct metal deposition of ss316l for metallic parts manufacturing. Phys Procedia 39:455–463

Dutta Majumdar J, Pinkerton A, Liu Z, Manna I, Li L (2005) Mechanical and electrochemical properties of multiple-layer diode laser cladding of 316L stainless steel. Appl Surf Sci 247:373–377

Neela V, De A (2009) Three-dimensional heat transfer analysis of LENSTM process using finite element method. Int J Adv Manuf Technol 45:935–943

Dutta Majumdar J, Pinkerton A, Liu Z, Manna I, Li L (2005) Microstructure characterisation and process optimization of laser assisted rapid manufacturing of 316L stainless steel. Appl Surf Sci 247:320–327

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amine, T., Newkirk, J.W. & Liou, F. An investigation of the effect of laser deposition parameters on characteristics of multilayered 316 L deposits. Int J Adv Manuf Technol 73, 1739–1749 (2014). https://doi.org/10.1007/s00170-014-5951-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5951-z