Abstract

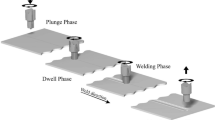

In the present paper, a tool with a flat pin was designed and utilized to friction stir spot weld acrylonitrile butadiene styrene sheets. Influences of welding parameters and pin geometries on joint morphology and mechanical performance were investigated. Results showed that rotational speed during plunging and stirring phase exerted a significant influence on the joint surface appearance and cross-sectional morphology while plunge rate and dwell time showed a slight effect. Secondary extrusion ring, rough weld surface, groove defects, and pores were observed under excessive stirring rotational speed. Spot weld diameter enlarged with the increase of the total tool rotation number in the plunging and stirring phase. Joint lap-shear tensile load varied significantly with the variation of the keyhole orientation. The comparison of the joints produced by different pin geometries showed that flat pin was optimal to fabricate joints with larger bonded region and lap-shear tensile load. With the increase of rotational speed or the decrease of plunge rate, joint shear strength reduced. The proper extension of dwell time under moderate rotational speed exerted a slight influence on the joint shear strength but showed a positive effect on the joint fracture load.

Similar content being viewed by others

References

Davies G (2003) Future trends in automotive body materials. Mater Autom Bodies 8:252–269

Sakano R, Murakami K, Yamashita K, Hyoe T, Fujimoto M, Inuzuka M, Nagao Y, Kashiki H (2001) Development of spot FSW robot system for automobile body members. In: Proceedings of the 3rd International Symposium of Friction Stir Welding, Kobe, Japan, pp. 645–650

Arici A, Mert Ş (2008) Friction stir spot welding of polypropylene. J Reinf Plast Compos 27(18):2001–2004

Mert Ş, Arici A (2011) Design of optimal joining for friction stir spot welding of poly-propylene sheets. Sci Technol Weld Join 16(6):522–527

Bilici MK (2012) Application of Taguchi approach to optimize friction stir spot welding parameters of polypropylene. Mater Des 35:113–119

Bilici MK, Yükler Aİ (2012) Influence of tool geometry and process parameters on macrostructure and static strength in friction stir spot welded polyethylene sheets. Mater Des 33:145–152

Kurtulmus M (2012) Friction stir spot welding parameters for polypropylene sheets. Sci Res Essays 7:947–956

Bilici MK, Yukler AI, Kastan A (2014) Effect of the tool geometry and welding parameters on the macrostructure, fracture mode and weld strength of friction-stir spot-welded polypropylene sheets. Mater Tehnol 48:705–711

Bilici MK (2012) Effect of tool geometry on friction stir spot welding of polypropylene sheets. Express Polym Lett 6:805–813

Bilici MK, Yukler AI (2012) Effects of welding parameters on friction stir spot welding of high density polyethylene sheets. Mater Des 33:545–550

Bilici MK, Yükler Aİ, Kurtulmuş M (2011) The optimization of welding parameters for friction stir spot welding of high density polyethylene sheets. Mater Des 32:4074–4079

Yan Y, Shen Y, Zhang W, Guan W (2017) Effects of friction stir spot welding parameters on morphology and mechanical property of modified cast nylon 6 joints produced by double-pin tool. Int J Adv Manuf Technol 92:2511–2523

Gonçalves J, Santos JFD, Canto LB, Amancio-Filho ST (2015) Friction spot welding of carbon fiber-reinforced polyamide66 laminate. Mater Lett 159:506–509

Paoletti A, Lambiase F, Ilio AD (2015) Optimization of friction stir welding of thermoplastics. Procedia CIRP 33:562–567

Paoletti A, Lambiase F, Ilio AD (2016) Analysis of forces and temperatures in friction spot stir welding of thermoplastic polymers. Int J Adv Manuf Technol 83(5):1395–1407

Lambiase F, Paoletti A, Ilio AD (2016) Effect of tool geometry on mechanical behavior of friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 88:3005–3016

Lambiase F, Paoletti A, Ilio AD (2016) Effect of tool geometry on loads developing in friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 87:2293–2303

Lambiase F, Paoletti A, Ilio AD (2016) Friction spot stir welding of polymers: control of plunging force. Int J Adv Manuf Technol 90:2827–2837

Dashatan SH, Azdast T, Ahmadi R, Bagheri A (2013) Friction stir spot welding of dissimilar polymethyl methacrylate and acrylonitrile butadiene styrene sheets. Mater Des 45(6):135–141

Yan Y, Shen Y, Zhang W, Hou W (2018) Friction stir spot welding ABS using triflute-pin tool: effect of process parameters on joint morphology, dimension and mechanical property. J Manuf Process 32:269–279

Yan Y, Shen Y, Hou W, Li J (2018) Friction stir spot welding thin acrylonitrile butadiene styrene sheets using pinless tool. Int J Adv Manuf Technol 97:2749–2755

Oliveira PHF, Amancio-Filho ST, Santos JFD, Hage E (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64(19):2098–2101

Gerlich A, Su P, North TH, Bendzsak GJ (2005) Friction stir spot welding of aluminum and magnesium alloys. Mater Forum 29:290–294

Capone C, Landro LD, Inzoli F, Penco M, Sartore L (2007) Thermal and mechanical degradation during polymer extrusion processing. Polym Eng Sci 47(11):1813–1819

Hattingh DG, Blignault C, Van Niekerk TI, James MN (2008) Characterization of the influences of FSW tool geometry on welding forces and weld tensile strength using an instrumented tool. J Mater Process Technol 203:46–57

Funding

This study work was supported by the National Natural Science Foundation of China (Grant No. 51475232). This work was supported by Funding for Outstanding Doctoral Dissertation in NUAA (No. BCXJ18-08). This work was supported by the fifth scientific and technological innovation funds in the college of materials science and technology of NUAA in 2017. This was also a project founded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yan, Y., Shen, Y., Lei, H. et al. Influence of welding parameters and tool geometry on the morphology and mechanical performance of ABS friction stir spot welds. Int J Adv Manuf Technol 103, 2319–2330 (2019). https://doi.org/10.1007/s00170-019-03703-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03703-4