Abstract

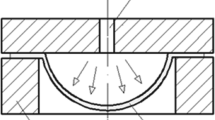

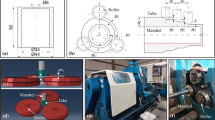

In the present work, effects of the hot spinning process on the spinnability of AZ31 blank to a tubular shape are investigated. The hot spinning process was carried out by an electrical heating system embedded inside the mandrel. Based on the results, the hot spinning below 250 °C led to fracture. At 250 °C, although deformation imposed no fracture, localized thinning limited the spinnability of the alloy. The spinnability was, however, quite well at the temperature range of 300–450 °C. At this range of temperature, it was found that despite different initial microstructures, the initial conditions of the material, i.e., annealing and as-received conditions, have no significant effect on the spinnability. This was attributed to the complete dynamic recrystallization above 300 °C. Regarding the roller path, two paths of linear and nonlinear paths were implemented. The results show that the nonlinear path of the roller failed to produce a sound tube even above 300 °C. Finite element simulations in combination with a ductile fracture criterion were employed to analyze the low spinnability of the AZ31 blank through this path. Based on the results, this path introduces higher longitudinal strain along with the combination of intensive tensile hydrostatic and longitudinal stresses within the workpiece wall. Such deformation conditions, therefore, cause circumferential cracks at the workpiece wall.

Similar content being viewed by others

References

Friedrich H, Schumann S (2001) Research for a “new age of magnesium” in the automotive industry. J Mater Process Technol 117(3):276–281. https://doi.org/10.1016/S0924-0136(01)00780-4

Joost WJ, Krajewski PE (2017) Towards magnesium alloys for high-volume automotive applications. Scr Mater 128:107–112. https://doi.org/10.1016/j.scriptamat.2016.07.035

Gupta M, Ling SNM (2011) Magnesium, magnesium alloys, and magnesium composites. Wiley

Pan F, Yang M, Chen X (2016) A review on casting magnesium alloys: modification of commercial alloys and development of new alloys. J Mater Sci Technol 32(12):1211–1221. https://doi.org/10.1016/j.jmst.2016.07.001

Avedesian MM, Baker H (Eds.) (1999) ASM specialty handbook: magnesium and magnesium alloys. ASM international

Doege E, Drder K (2001) Sheet metal forming of magnesium wrought alloys - formability and process technology. J Mater Process Technol 115(1):14–19. https://doi.org/10.1016/S0924-0136(01)00760-9

Ghandehari Ferdowsi MR, Mazinani M, Ebrahimi GR (2014) Effects of hot rolling and inter-stage annealing on the microstructure and texture evolution in a partially homogenized AZ91 magnesium alloy. J Mater Sci Eng A 606:214–227. https://doi.org/10.1016/j.msea.2014.03.104

Hadadzadeh A, Wells MA, Shaha SK, Jahed H, Williams BW (2017) Role of compression direction on recrystallization behavior and texture evolution during hot deformation of extruded ZK60 magnesium alloy. J Alloys Compd 702:274–289. https://doi.org/10.1016/j.jallcom.2017.01.236

Huang GS, Wang LF, Pan FS, Ma MT (2014) The formability and hot stamping of magnesium alloy sheets. Adv Mater Res 1063:215–218. https://doi.org/10.4028/www.scientific.net/AMR.1063.215

Yang H, Huang L, Zhan M (2010) Coupled thermo-mechanical FE simulation of the hot splitting spinning process of magnesium alloy AZ31. Comput Mater Sci 47(3):857–866. https://doi.org/10.1016/j.commatsci.2009.11.014

Kim HS, Koç M (2008) Numerical investigations on springback characteristics of aluminum sheet metal alloys in warm forming conditions. J Mater Process Technol 204(1–3):370–383. https://doi.org/10.1016/j.jmatprotec.2007.11.059

Xie H, Wang Q, Liu K, Peng F, Dong X, Wang J (2015) Investigation of influence of direct-current pulses on springback during V-bending of AZ31B magnesium alloy sheet. J Mater Process Technol 219:321–327. https://doi.org/10.1016/j.jmatprotec.2014.12.011

Wong CC, Dean TA, Lin J (2003) A review of spinning, shear forming and flow forming processes. Int J Mach Tools Manuf 43(14):1419–1435. https://doi.org/10.1016/S0890-6955(03)00172-X

Music O, Allwood JM, Kawai K (2010) A review of the mechanics of metal spinning. J Mater Process Technol 210(1):3–23. https://doi.org/10.1016/j.jmatprotec.2009.08.021

Kalpakjian S, Rajagopal S (1982) Spinning of tubes: a review. J Appl Metalwork 2(3):211–223. https://doi.org/10.1007/bf02834039

Xia Q, Xiao G, Long H, Cheng X, Sheng X (2014) A review of process advancement of novel metal spinning. Int J Mach Tools Manuf 85:100–121. https://doi.org/10.1016/j.ijmachtools.2014.05.005

Xia Q, Cheng X, Long H, Ruan F (2012) Finite element analysis and experimental investigation on deformation mechanism of non-axisymmetric tube spinning. Int J Adv Manuf Technol 59(1):263–272. https://doi.org/10.1007/s00170-011-3494-0

Xia QX, Lai ZY, Long H, Cheng XQ (2013) A study of the spinning force of hollow parts with triangular cross sections. Int J Adv Manuf Technol 68(9):2461–2470. https://doi.org/10.1007/s00170-013-4847-7

Hosford WF, Caddell RM (1993) Metal forming: mechanics and metallurgy. Cambridge University Press

Li L-L, Cai Z-Y, Xu H-Q, Wang M, Yu J (2014) Research on AZ31 sheet one-pass hot spinning based on orthogonal experiment design. Int J Adv Manuf Technol 75(5):897–907. https://doi.org/10.1007/s00170-014-6186-8

Fong KS, Wong CC, Atsushi D (2010) Experimental investigation of flaring in the warm flow-forming of AZ31 magnesium cups. Key Engineering Materials, Trans Tech Publ 447:427–431. https://doi.org/10.4028/www.scientific.net/KEM.447-448.427

Cao Z, Wang F, Wan Q, Zhang Z, Jin L, Dong J (2015) Microstructure and mechanical properties of AZ80 magnesium alloy tube fabricated by hot flow forming. Mater Des 67:64–71. https://doi.org/10.1016/j.matdes.2014.11.016

Yoshihara S, Mac Donald B, Hasegawa T, Kawahara M, Yamamoto H (2004) Design improvement of spin forming of magnesium alloy tubes using finite element. J Mater Process Technol 153-154:816–820. https://doi.org/10.1016/j.jmatprotec.2004.04.386

Murata M, Kuboki T, Murai T (2005) Compression spinning of circular magnesium tube using heated roller tool. J Mater Process Technol 162-163:540–545. https://doi.org/10.1016/j.jmatprotec.2005.02.199

Mei Z, He Y, Jing G, Wang X-x (2015) Review on hot spinning for difficult-to-deform lightweight metals. Trans Nonferrous Metals Soc China 25(6):1732–1743. https://doi.org/10.1016/S1003-6326(15)63778-5

Kwak TY, Lim HK, Kim WJ (2016) The effect of 0.5 wt.% Ca addition on the hot compressive characteristics and processing maps of the cast and extruded Mg–3Al–1Zn alloys. J Alloys Compd 658:157–169. https://doi.org/10.1016/j.jallcom.2015.10.193

Gur M, Tirosh J (1982) Plastic flow instability under compressive loading during shear spinning process. J Eng Ind 104:17–22

Mohebbi MS, Akbarzadeh A (2010) Experimental study and FEM analysis of redundant strains in flow forming of tubes. J Mater Process Technol 210(2):389–395. https://doi.org/10.1016/j.jmatprotec.2009.09.028

Zhang D-f, Hu H-j, Pan F-s, Yang M-b, Zhang J-p (2010) Numerical and physical simulation of new SPD method combining extrusion and equal channel angular pressing for AZ31 magnesium alloy. Trans Nonferrous Metals Soc China 20(3):478–483. https://doi.org/10.1016/s1003-6326(09)60165-5

JMatPro the materials property simulation package public release Version 6.1. Sente Software Ltd.

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena. Elsevier, Oxford

Abaqus analysis user’s manual (2012). ABAQUS Inc Version 6.12

Liu JG, Liu W (2012) Evaluation of seven ductile fracture criteria for failure prediction of AZ31 sheet in warm forming. Adv Mater Res 482-484:1947–1950. https://doi.org/10.4028/www.scientific.net/AMR.482-484.1947

Nguyen D-T, Park J-G, Kim Y-S (2010) Ductile fracture prediction in rotational incremental forming for magnesium alloy sheets using combined kinematic/isotropic hardening model. Metall Mater Trans A 41(8):1983–1994. https://doi.org/10.1007/s11661-010-0235-1

Oyane M, Sato T, Okimoto K, Shima S (1980) Criteria for ductile fracture and their applications. J Mech Work Technol 4(1):65–81. https://doi.org/10.1016/0378-3804(80)90006-6

Cai Z, Chen F, Ma F, Guo J (2016) Dynamic recrystallization behavior and hot workability of AZ41M magnesium alloy during hot deformation. J Alloys Compd 670:55–63. https://doi.org/10.1016/j.jallcom.2016.02.033

Prasad YVRK, Rao KP (2008) Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: anisotropy of hot workability. Mater Sci Eng A 487(1):316–327. https://doi.org/10.1016/j.msea.2007.10.038

Atik K, Efe M (2018) Twinning-induced shear banding and its control in rolling of magnesium. Mater Sci Eng A 725:267–273. https://doi.org/10.1016/j.msea.2018.03.121

Klimanek P, Pötzsch A (2002) Microstructure evolution under compressive plastic deformation of magnesium at different temperatures and strain rates. Mater Sci Eng A 324(1):145–150. https://doi.org/10.1016/S0921-5093(01)01297-7

Dowling NE (2012) Mechanical behavior of materials: engineering methods for deformation, fracture, and fatigue. Pearson Prentice Hall

Gouveia BPPA, Rodrigues JMC, Martins PAF (2000) Ductile fracture in metalworking: experimental and theoretical research. J Mater Process Technol 101(1):52–63. https://doi.org/10.1016/S0924-0136(99)00449-5

Clift SE, Hartley P, Sturgess CEN, Rowe GW (1990) Fracture prediction in plastic deformation processes. Int J Mech Sci 32(1):1–17. https://doi.org/10.1016/0020-7403(90)90148-C

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and lode dependence. Int J Plast 24(6):1071–1096. https://doi.org/10.1016/j.ijplas.2007.09.004

Novella MF, Ghiotti A, Bruschi S, Bariani PF (2015) Ductile damage modeling at elevated temperature applied to the cross wedge rolling of AA6082-T6 bars. J Mater Process Technol 222:259–267. https://doi.org/10.1016/j.jmatprotec.2015.01.030

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohebbi, M.S., Rahimi pour, M. Effects of temperature, initial conditions, and roller path on hot spinnability of AZ31 alloy. Int J Adv Manuf Technol 103, 377–388 (2019). https://doi.org/10.1007/s00170-019-03528-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03528-1