Abstract

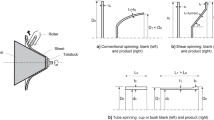

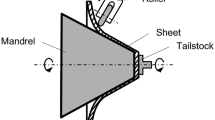

Spinning of tubes involves progressive localized deformation of a cylindrical ring between a rotating mandrel and a roller. The resultant product is a tube whose wall thickness is determined by the gap between the mandrel and roller. The process is also known as shear forming, flow turning, spin forging, rotary extrusion, roll extrusion, flow forming, hydrospinning, rotoforming, and floturning. Spinning of tubes is reviewed herein with the objective of providing an understanding of the basic mechanisms underlying the process,important variables and their influence on the process, some of the simpler tooling techniques that have evolved for specific parts, and the types of parts to which the process has been successfully applied in industry.

Similar content being viewed by others

References

C.L. Packham: “Metal Spinning and Shear and Flow Forming,”Metallurgia and Metal Forming, June 1976, pp. 168–70; July 1976, pp. 203–06; August 1976, pp. 250–52; September 1976, pp. 281–85.

C. Wick: “Metal Spinning: A Review and Update,”Manufacturing Engineering, January 1978, pp. 73–77.

Metal Deformation Processing, Defense Metals Information Center, Battelle Memorial Institute, Columbus, Ohio, 1966, vol II, report no. 226, pp. 49–66.

“Rotary Metalworking Processes,”Proceedings, First Int. Conf., IFS (Conferences) Ltd., Bedford, U. K., 1979.

K. W. Stalker and K. W. Moore: “Cold Power Spinning Saves Material, Cuts Costs,”American Machinist, May 9, 1955.

“Power Spinning Conical and Tubular Parts,”Product Engineering, August 1956.

J. Genis and W. Mallindine: “Rotary Extrusion Reduces Costs and Saves Material,”Machinery, NY, April 1958, pp. 115–21.

J.H. Peters: “Flow Turning to Increase Strength, Save Weight, and Reduce Costs,” ASME Paper No. 59-A-277, 1959.

L. E. Zwissler: “Spinning Makes Stronger Rocket Cases,”Metal Progress, December 1960.

“Heavy Flow-Forming,”Aircraft Production, November 1962, pp. 374–76.

D.J. Campion: “Spinning and Related Forming Techniques with Particular Reference to Maraging Steel,”Sheet Metal Industries, March 1967, pp. 160–66.

G. E. Gott, J. M. Lynch, and S. M. Jacobs: “Are Shear Spinning and Roll Extrusion Production Processes for Large Parts?”Metal Progress, March 1968, pp. 95–99.

“Case Histories Demonstrate Metal Spinning’s Virtues,”Modern Metals, June 1978, pp. 46–49.

D. H. Pollitt: “The Practice and Potential of Flow Forming Processes,” inRotary Metalworking Processes, Proceedings, First Int. Conf., IFS (Conferences) Ltd., Bedford, U. K., 1979.

“Shear Forming of Thin-Wall Seamless Tubes,”Machinery, January 1964, pp. 120–21.

A. W. Emestus: “Roll Extrusion, A New Metal-Forming Technique,”American Machinist, June 29, 1959, pp. 84–86.

D. L. Corn: “Roll Extruding Precision Seamless Pipe and Tubing,”Metal Progress, June 1977, pp. 28–31. See also “Recent Advances in Roll Extrusion,”Rotary Metalworking Processes, Proceedings,First Int. Conf., IFS (Conferences) Ltd., Bedford, U.K., 1979, pp. 243–50.

S. Rajagopal and S. Kalpakjian: “Internal Shear Forging Processes for Missile Primary Structures,” IIT Research Institute, Final Report under U. S. Army Missile Command Contract No. DAAK40-78-C-0264, July 1981.

J. M. Steichen and R. L. Knecht: “Mechanical Properties of Roll Extruded Nuclear Reactor Piping,” ASME Paper No. 75-PVP-41, 1975.

“Shear Forming: How It Affects Properties,”American Machinist, July 6, 1965, pp. 57–59.

E. S. Jones: “Aus-Shear Forming of Low Alloy Steel Cylinders,” General Electric Co., Cincinnati, Ohio,ca. 1960.

S. Kalpakjian: “An Application of Theory to an Engineering Problem: Power Spinning,”Fundamentals of Deformation Processing, Syracuse University Press, 1964, Chapter IV, pp. 71–103.

E. Thomasett: “Kräfte und Grenzformänderungen beim Abstreckdrücken zylindrischer, Rotationssymmetrisches Hohlkörper aus Aluminium,” Doctoral Dissertation, University of Stuttgart, 1961.

S. Kalpakjian: “An Experimental Study of Plastic Deformation in Power Spinning,”C.I.R.P. Annals, 1962, vol. 10, pp. 58–64.

H. Jacob: “Erfahrungen beim Fliessdrücken zylindrischer Werkstücke,”Fertigungstechnik und Betrieb, March 1962, vol. 12, pp. 169–78.

E. Siebel and K. A. Dröge: “Forces and Material Flow in Spinning,”Werkstattstechnik und Maschinenbau, January 1955, vol. 45, pp. 6–9. (See alsoThe Engineers’ Digest, May 1955, vol. 16, no. 5, pp. 193–95).

S. Kalpakjian: “Maximum Reduction in Power Spinning of Tubes,” Trans. ASME,J. Eng. Ind., 1964, vol. 86, pp. 49–54.

C. H. Wells: “The Control of Buildup and Diametral Growth in Shear Forming,” Trans. ASME,J. Eng. Ind., 1968, vol. 90, pp. 63–70.

H. J. Dreikandt: “Untersuchung über das Drückwalzen zylindrischer Hohlkörper und Beitrag zur Berechnung der gedrückten Fläche und der Dräfte,” University of Stuttgart, 1973.

S. Kalpakjian: “Chevron Fracture in Tube Reduction by Spinning,”Advances in Research on the Strength and Fracture of Materials, Pergamon Press, NY, 1977, vol. 2A, pp. 443–50.

A. K. Cruden: Report No. 341, National Engineering Laboratory, 1968; also M.G. Cockroft inDuctility, ASM, 1968, p. 218.

M. Hayama and H. Kudo: “Analysis of Diametral Growth and Working Forces in Tube Spinning,”Bulletin of the Japan Society of Mechanical Engineers, 1979, vol. 22, pp. 776–84.

M. Hayama and H. Kudo: “Experimental Study of Tube Spinning,”Bulletin of the Japan Society of Mechanical Engineers, 1979, vol. 22, pp. 769–75.

H. Jacob and F. Garreis: “Rollenanordnung und Rollenform beim Fliessdrücken zylindrischer Körper,”Fertigungstechnik und Betrieb, May 1965, vol. 15, no. 5, pp. 279–83.

H. Jacob and F. Garreis: “Berechnung der uftretenden Kräfte beim Fliessdrücken zylindrischer Hohlkörper,”Fertigungstechnik und Betrieb, August 1964, vol. 14, no. 8, pp. 493–97.

H. Jacob and F. Garreis: “Fliessdrücken mit Schrägstellung der Rollen und deren Auswirkung und den Werkstoffluss und Unformkräfte (Dreh-Umformmaschine)”Fertigungstechnik und Betrieb, January 1966, vol. 16, no. 1, pp. 42–45.

V. I. Eliseev and E. I. Isachenkov: “Selection of Force Parameters when How-Turning Cylindrical Components,”Russian Engineering Journal (Translation of Vestnik Mashinostroeniia), 1969, vol. 49, no. 11, pp. 68–71.

P. Bennich: “Tube Spinning,”Int. Journal Prod. Res., 1976, vol. 14, no. 1, pp. 11–21.

J. A. Bennaton and E. Appleton: “An Experimental Metalforming Machine and Its Application to Cylindrical Flowturning,” inRotary Metalworking Processes, Ref. 4.

T. Rammohan and R. Mishra: “Studies on Power Spinning of Tubes,”Int. Journal Prod. Res., 1972, vol. 10, no. 4, pp. 351–64.

S. Kobayashi and E. G. Thomsen: “Theory of Spin Forging,”C.I.R.P. Annals, 1962, vol. 10, no. 2, pp. 114–23.

S. Kalpakjian: “A Study of the Mechanics of Tube Spinning as Related to Performance,” The Cincinnati Milling Machine Company, Final Report under Project No. F-98060-7, April 1962.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kalpakjian, S., Rajagopal, S. Spinning of tubes: A review. J. Applied Metalworking 2, 211–223 (1982). https://doi.org/10.1007/BF02834039

Issue Date:

DOI: https://doi.org/10.1007/BF02834039