Abstract

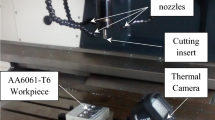

Owing to superior physio-chemical characteristics, titanium alloys are widely adopted in numerous fields such as medical, aerospace, and military applications. However, titanium alloys have poor machinability due to its low thermal conductivity which results in high temperature during machining. Numerous lubrication and cooling techniques have already been employed to reduce the harmful environmental footprints and temperature elevation and to improve the machining of titanium alloys. In this current work, an attempt has been made to evaluate the effectiveness of two cooling and lubrication techniques namely cryogenic cooling and hybrid nanoadditive–based minimum quantity lubrication (MQL). The key objective of this experimental research is to compare the influence of cryogenic CO2 and hybrid nanofluid–based MQL techniques for turning Ti–6Al–4V. The used hybrid nanofluid is alumina (Al2O3) with multi-walled carbon nanotubes (MWCNTs) dispersed in vegetable oil. Taguchi-based L9 orthogonal-array was used for the design of the experiment. The design variables were cutting speed, feed rate, and cooling technique. Results showed that the hybrid nanoadditives reduced the average surface roughness by 8.72%, cutting force by 11.8%, and increased the tool life by 23% in comparison with the cryogenic cooling. Nevertheless, the cryogenic technique showed a reduction of 11.2% in cutting temperature compared to the MQL-hybrid nanofluids at low and high levels of cutting speed and feed rate. In this regard, a milestone has been achieved by implementing two different sustainable cooling/lubrication techniques.

Similar content being viewed by others

References

Mia M, Dhar NR (2017) Influence of single and dual cryogenic jets on machinability characteristics in turning of Ti-6Al-4V. Proc Inst Mech Eng B J Eng Manuf 233:711–726. https://doi.org/10.1177/0954405417737581

Zhao W, Gong L, Ren F, Li L, Xu Q, Khan AM (2018) Experimental study on chip deformation of Ti-6Al-4V titanium alloy in cryogenic cutting. Int J Adv Manuf Technol 96:4021–4027. https://doi.org/10.1007/s00170-018-1890-4

Ginting A, Nouari M (2006) Experimental and numerical studies on the performance of alloyed carbide tool in dry milling of aerospace material. Int J Mach Tools Manuf 46:758–768. https://doi.org/10.1016/j.ijmachtools.2005.07.035

Iqbal A, Biermann D, Abbas H, al-Ghamdi KA, Metzger M (2018) Machining β-titanium alloy under carbon dioxide snow and micro-lubrication: a study on tool deflection, energy consumption, and tool damage. Int J Adv Manuf Technol 97:4195–4208. https://doi.org/10.1007/s00170-018-2267-4

Mia M, Dhar NR (2018) Effects of duplex jets high-pressure coolant on machining temperature and machinability of Ti-6Al-4V superalloy. J Mater Process Technol 252:688–696. https://doi.org/10.1016/j.jmatprotec.2017.10.040

Khan MA, Mia M, Dhar NR (2017) High-pressure coolant on flank and rake surfaces of tool in turning of Ti-6Al-4V: investigations on forces, temperature, and chips. Int J Adv Manuf Technol 90:1977–1991. https://doi.org/10.1007/s00170-016-9511-6

Ezugwu EO, Bonney J, Da Silva RB, Çakir O (2007) Surface integrity of finished turned Ti-6Al-4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tools Manuf 47:884–891. https://doi.org/10.1016/j.ijmachtools.2006.08.005

Zhang C, Zhang S, Yan X, Zhang Q (2016) Effects of internal cooling channel structures on cutting forces and tool life in side milling of H13 steel under cryogenic minimum quantity lubrication condition. Int J Adv Manuf Technol 83:975–984. https://doi.org/10.1007/s00170-015-7644-7

Jeevan TP, Jayaram SR (2018) Performance evaluation of Jatropha and Pongamia oil based environmentally friendly cutting fluids for turning AA 6061. Advances in Tribology 2018:1–9. https://doi.org/10.1155/2018/2425619

Pusavec F, Deshpande A, Yang S, M’Saoubi R, Kopac J, Dillon OW Jr, Jawahir IS (2014) Sustainable machining of high temperature nickel alloy—Inconel 718: part 1—predictive performance models. J Clean Prod 81:255–269. https://doi.org/10.1016/j.jclepro.2014.06.040

Goindi GS, Sarkar P (2017) Dry machining: a step towards sustainable machining—challenges and future directions. J Clean Prod 165:1557–1571. https://doi.org/10.1016/j.jclepro.2017.07.235

Mia M, Gupta MK, Singh G, Królczyk G, Pimenov DY (2018) An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J Clean Prod 187:1069–1081. https://doi.org/10.1016/j.jclepro.2018.03.279

Lei S, Liu W (2002) High-speed machining of titanium alloys using the driven rotary tool. Int J Mach Tools Manuf 42:653–661. https://doi.org/10.1016/S0890-6955(02)00012-3

Weinert K, Inasaki I, Sutherland JW, Wakabayashi T (2004) Dry machining and minimum quantity lubrication. CIRP Ann Manuf Technol 53:511–537. https://doi.org/10.1016/S0007-8506(07)60027-4

Maruda RW, Krolczyk GM, Feldshtein E, Pusavec F, Szydlowski M, Legutko S, Sobczak-Kupiec A (2016) A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int J Mach Tools Manuf 100:81–92. https://doi.org/10.1016/j.ijmachtools.2015.10.008

Fratila D (2010) Macro-level environmental comparison of near-dry machining and flood machining. J Clean Prod 18:1031–1039. https://doi.org/10.1016/j.jclepro.2010.01.017

Mia M, Morshed MS, Kharshiduzzaman M et al (2018) Prediction and optimization of surface roughness in minimum quantity coolant lubrication applied turning of high hardness steel. Measurement: Journal of the International Measurement Confederation. https://doi.org/10.1016/j.measurement.2018.01.012

Hao X, Cui W, Li L, Li H, Khan AM, He N (2018) Cutting performance of textured polycrystalline diamond tools with composite lyophilic/lyophobic wettabilities. J Mater Process Technol 260:1–8. https://doi.org/10.1016/j.jmatprotec.2018.04.049

Mia M (2017) Multi-response optimization of end milling parameters under through-tool cryogenic cooling condition. Measurement 111:134–145. https://doi.org/10.1016/j.measurement.2017.07.033

Mia M, Gupt MK, Lozanod JA, Carou D, Yu D, Pimenov G, Królczyk AMKNRD (2018) Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J Clean Prod 210:121–133. https://doi.org/10.1016/j.jclepro.2018.10.334

Kalita P, Malshe AP, Arun Kumar S, Yoganath VG, Gurumurthy T (2012) Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil-based nanolubricants. J Manuf Process 14:160–166. https://doi.org/10.1016/j.jmapro.2012.01.001

Saidur R, Leong KY, Mohammad HA (2011) A review on applications and challenges of nanofluids. Renew Sust Energ Rev 15:1646–1668. https://doi.org/10.1016/j.rser.2010.11.035

Sidik NAC, Samion S, Ghaderian J, Yazid MNAWM (2017) Recent progress on the application of nanofluids in minimum quantity lubrication machining: a review. Int J Heat Mass Transf 108:79–89

Paul S, Singh AK, Ghosh A (2017) Grinding of Ti-6Al-4V under small quantity cooling lubrication environment using alumina and MWCNT nanofluids. Mater Manuf Process 32:608–615. https://doi.org/10.1080/10426914.2016.1257797

Prabhu S, Uma M, Vinayagam BK (2015) Surface roughness prediction using Taguchi-fuzzy logic-neural network analysis for CNT nanofluids based grinding process. Neural Comput & Applic 26:41–55. https://doi.org/10.1007/s00521-014-1696-8

Raju RA, Andhare A, Sahu NK (2017) Performance of multi-walled carbon nanotube-based nanofluid in turning operation. Mater Manuf Process 32:1490–1496. https://doi.org/10.1080/10426914.2017.1279291

Sharma P, Sidhu BS, Sharma J (2015) Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J Clean Prod 108:72–79. https://doi.org/10.1016/j.jclepro.2015.07.122

Mao C, Zhang J, Huang Y, Zou H, Huang X, Zhou Z (2013) Investigation on the effect of nanofluid parameters on MQL grinding. Mater Manuf Process 28:436–442. https://doi.org/10.1080/10426914.2013.763970

Vasu V, Reddy GPK (2012) Effect of minimum quantity lubrication with Al2O3nanoparticles on surface roughness, tool wear and temperature dissipation in machining Inconel 600 alloy. Proceedings of the Institution of Mechanical Engineers, Part N: Journal of Nanoengineering and Nanosystems 225:3–16

Wang Y, Li C, Zhang Y, Li B, Yang M, Zhang X, Guo S, Liu G, Zhai M (2017) Comparative evaluation of the lubricating properties of vegetable-oil-based nanofluids between frictional test and grinding experiment. J Manuf Process 26:94–104. https://doi.org/10.1016/j.jmapro.2017.02.001

Khan AM, Jamil M, Mia M, Pimenov DY, Gasiyarov VR, Gupta MK, He N (2018) Multi-objective optimization for grinding of AISI D2 steel with Al2O3 wheel under MQL. Materials 11:2269. https://doi.org/10.3390/ma11112269

Hegab H, Darras B, Kishawy HA (2018) Sustainability assessment of machining with nano-cutting fluids. Procedia Manufacturing 26:245–254. https://doi.org/10.1016/j.promfg.2018.07.033

Zhang Y, Li C, Jia D, Li B, Wang Y, Yang M, Hou Y, Zhang X (2016) Experimental study on the effect of nanoparticle concentration on the lubricating property of nanofluids for MQL grinding of Ni-based alloy. J Mater Process Technol 232:100–115. https://doi.org/10.1016/j.jmatprotec.2016.01.031

Hamzah MH, Sidik NAC, Ken TL, Mamat R, Najafi G (2017) Factors affecting the performance of hybrid nanofluids: a comprehensive review. Int J Heat Mass Transf 115:630–646. https://doi.org/10.1016/j.ijheatmasstransfer.2017.07.021

Sarkar J, Ghosh P, Adil A (2015) A review on hybrid nanofluids: recent research, development and applications. Renew Sust Energ Rev 43:164–177

Abbasi SM, Rashidi A, Nemati A, Arzani K (2013) The effect of functionalisation method on the stability and the thermal conductivity of nanofluid hybrids of carbon nanotubes/gamma alumina. Ceram Int 39:3885–3891. https://doi.org/10.1016/j.ceramint.2012.10.232

Sharma AK, Tiwari AK, Dixit AR (2018) Prediction of temperature distribution over cutting tool with alumina-MWCNT hybrid nanofluid using computational fluid dynamics (CFD) analysis. Int J Adv Manuf Technol 97:427–439. https://doi.org/10.1007/s00170-018-1946-5

Singh RK, Sharma AK, Dixit AR, Tiwari AK, Pramanik A, Mandal A (2017) Performance evaluation of alumina-graphene hybrid nano-cutting fluid in hard turning. J Clean Prod 162:830–845. https://doi.org/10.1016/j.jclepro.2017.06.104

Hegab H, Kishawy H (2018) Towards sustainable machining of Inconel 718 using nano-fluid minimum quantity lubrication. Journal of Manufacturing and Materials Processing 2:50. https://doi.org/10.3390/jmmp2030050

Aggarwal A, Singh H, Kumar P, Singh M (2008) Optimization of multiple quality characteristics for CNC turning under cryogenic cutting environment using desirability function. J Mater Process Technol 205:42–50. https://doi.org/10.1016/j.jmatprotec.2007.11.105

Biček M, Dumont F, Courbon C, Pušavec F, Rech J, Kopač J (2012) Cryogenic machining as an alternative turning process of normalized and hardened AISI 52100 bearing steel. J Mater Process Technol 212:2609–2618. https://doi.org/10.1016/j.jmatprotec.2012.07.022

Sun Y, Huang B, Puleo DA, Jawahir IS (2015) Enhanced machinability of Ti-5553 alloy from cryogenic machining: comparison with MQL and flood-cooled machining and modeling. Procedia CIRP 31:477–482

Dilip Jerold B, Pradeep Kumar M (2011) Experimental investigation of turning AISI 1045 steel using cryogenic carbon dioxide as the cutting fluid. J Manuf Process 13:113–119. https://doi.org/10.1016/j.jmapro.2011.02.001

Fratila D (2016) Numerical and experimental approach of cutting temperatures to green turning of 42CrMo4 steel. Mater Manuf Process 31:657–666. https://doi.org/10.1080/10426914.2015.1004708

Hegab H, Umer U, Deiab I, Kishawy H (2018) Performance evaluation of Ti–6Al–4V machining using nano-cutting fluids under minimum quantity lubrication. Int J Adv Manuf Technol 95:4229–4241. https://doi.org/10.1007/s00170-017-1527-z

Nine MJ, Batmunkh M, Kim J-H, Chung HS, Jeong HM (2012) Investigation of Al2O3-MWCNTs hybrid dispersion in water and their thermal characterization. J Nanosci Nanotechnol 12:4553–4559. https://doi.org/10.1166/jnn.2012.6193

Bagherzadeh A, Budak E (2018) Investigation of machinability in turning of difficult-to-cut materials using a new cryogenic cooling approach. Tribol Int 119:510–520. https://doi.org/10.1016/j.triboint.2017.11.033

O’Sullivan D, Cotterell M (2001) Temperature measurement in single point turning. J Mater Process Technol 118:301–308. https://doi.org/10.1016/S0924-0136(01)00853-6

Sharma AK, Katiyar JK, Bhaumik S, Roy S (2018) Influence of alumina/MWCNT hybrid nanoparticle additives on tribological properties of lubricants in turning operations. Friction. https://doi.org/10.1007/s40544-018-0199-5

Skerlos SJ, Hayes KF, Clarens AF, Zhao F (2008) Current advances in sustainable metalworking fluids research. International Journal of Sustainable Manufacturing 1:180. https://doi.org/10.1504/IJSM.2008.019233

Yıldırım ÇV, Kıvak T, Sarıkaya M, Erzincanlı F (2017) Determination of MQL parameters contributing to sustainable machining in the milling of nickel-base superalloy waspaloy. Arab J Sci Eng 42:4667–4681. https://doi.org/10.1007/s13369-017-2594-z

Mia M, Al Bashir M, Dhar NR (2016) Modeling of principal flank wear: an empirical approach combining the effect of tool, environment and workpiece hardness. Journal of The Institution of Engineers (India): Series C 97:517–526. https://doi.org/10.1007/s40032-016-0262-9

Sharma AK, Tiwari AK, Dixit AR, Singh RK, Singh M (2018) Novel uses of alumina/graphene hybrid nanoparticle additives for improved tribological properties of lubricant in turning operation. Tribol Int 119:99–111. https://doi.org/10.1016/j.triboint.2017.10.036

Deng J (2011) Adhesion wear on tool rake and flank faces in dry cutting of Ti-6Al-4V. Chinese Journal of Mechanical Engineering 24:1089. https://doi.org/10.3901/CJME.2011.06.1089

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jamil, M., Khan, A.M., Hegab, H. et al. Effects of hybrid Al2O3-CNT nanofluids and cryogenic cooling on machining of Ti–6Al–4V. Int J Adv Manuf Technol 102, 3895–3909 (2019). https://doi.org/10.1007/s00170-019-03485-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03485-9