Abstract

Tube spinning technology represents a process with high forming precision and good flexibility and is increasingly being used in the manufacture of bimetal composite tubular structures. In the present study, a forming analysis of clad tube and base tube in spinning process was conducted through numerical simulations and experiments. There was an equivalent stress transition on the interface since the stress transmission was retarded from clad tube to base tube. The yield strength became a main consideration during a design bimetal composite tube. Meanwhile, the strain distributions in axial direction, tangential direction, and radial direction were also investigated to determine the deformation characteristics of each component. As the press amount increased, the strain of clad tube changed more than base tube. As the feed rate increased, the strain decreased in axial direction and tangential direction but almost unchanged in radial direction. Simultaneously, a method for controlling the wall thickness of the clad tube and the base tube is proposed. These results to guide the design of bimetal tube composite spinning process have the certain meanings.

Similar content being viewed by others

References

Wang H, Han J, Hui Z (2013) The basic research on numerical simulation of bimetal composited T-tube through hydraulic bulging. Appl Mech Mater 278-280:487–490

Khosravifard A, Ebrahimi R (2010) Investigation of parameters affecting interface strength in Al/Cu clad bimetal rod extrusion process. Mater Des 31(1):493–499

Shaparev AV, Savin I (2016) Calculation of the amount of the reduction required for the formation of compound layers during cold rolling of bimetals. Mater Sci Forum 870:328–333

Halaczek D (2016) Analysis of manufacturing bimetallic tubes by the cold drawing process. Arch Metall Mater 61(1):241–248

Guo X et al (2013) Effects of the inner mould material on the aluminium–316L stainless steel explosive clad pipe. Mater Des 49:116–122

Sponseller DL, Timmons GA, Bakker WT (1998) Development of clad boiler tubes extruded from bimetallic centrifugal castings. J Mater Eng Perform 7(2):227–238

Yu H, Fan Z, Li C (2014) Magnetic pulse cladding of aluminum alloy on mild steel tube. J Mater Process Technol 214(2):141–150

Xia Q, Xiao G, Long H et al (2014) A review of process advancement of novel metal spinning. Int J Mach Tool Manu 85(7):100–121

Mohebbi MS, Akbarzadeh A (2010) A novel spin-bonding process for manufacturing multilayered clad tubes. J Mater Process Technol 210(3):510–517

Mohebbi MS, Akbarzadeh A (2010) Accumulative spin-bonding (ASB) as a novel SPD process for fabrication of nanostructured tubes. Mater Sci Eng A 528(1):180–188

Mohebbi MS, Akbarzadeh A (2011) Fabrication of copper/aluminum composite tubes by spin-bonding process: experiments and modeling. Int J Adv Manuf Technol 54(9–12):1043–1055

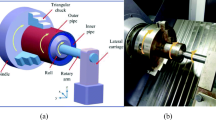

Jiang S, Zhang Y, Zhao Y, et al. (2016) Investigation of interface compatibility during ball spinning of composite tube of copper and aluminum. Int J Adv Manuf Technol:1–8

Zhang Z, Xu W, Shan D (2014) An analytical model on spin-bonding of composite tube. Procedia Eng 81:2024–2029

Xu W et al (2017) Effect of heat treatment and initial thickness ratio on spin bonding of 3A21/5A03 composite tube. J Mater Process Technol 247:143–157

Zhang Z et al (2018) Fabrication of steel/aluminum clad tube by spin bonding and annealing treatment. Int J Adv Manuf Technol 94(9–12):3605–3617

Bonet J, Kulasegaram S (2000) Correction and stabilization of smooth particle hydrodynamics methods with applications in metal forming simulations. Int J Numer Methods Eng 47(6):1189–1214

Zoghi H, Arezoodar AF, Sayeaftabi M (2013) Enhanced finite element analysis of material deformation and strain distribution in spinning of 42CrMo steel tubes at elevated temperature. Mater Des 47(9):234–242

Thamburaja P, Ekambaram R (2007) Coupled thermo-mechanical modelling of bulk-metallic glasses: theory, finite-element simulations and experimental verification. J MECH PHYS SOLIDS 55(6):1236–1273

Sonmez FO, Demir A (2007) Analytical relations between hardness and strain for cold formed parts. J Mater Process Technol 186(1):163–173

Bay N, Clemensen C, Juelstorp O, et al(1985) Bond strength in cold roll bonding[J]. CIRP ANN-MANUF TECHN 34(1):221–224

Jia Z, Han ZR, Xu Q et al (2015) Effects of processing parameters on the surface quality of square section die-less spinning. Int J Adv Manuf Technol 80(9–12):1689–1700

Funding

This work was supported by the Natural Science Foundation of Jiangsu Province (No. BK20170788).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, K., Yuan, Q., Tao, J. et al. Analysis of the forming characteristics for Cu/Al bimetal tubes produced by the spinning process. Int J Adv Manuf Technol 101, 147–155 (2019). https://doi.org/10.1007/s00170-018-2836-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2836-6