Abstract

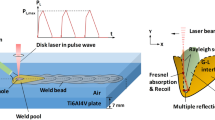

The influences of reduced ambient pressure on weld formation and pore defects were investigated by establishing a three-dimensional mathematical model for laser welding of aluminum alloy. The model was based on beam transmission with multiple reflection in the keyhole. The attenuation of the laser energy and the refraction of the laser beam by metal vapor plume above the keyhole were considered as a part of the heat source. The keyhole dynamics and molten pool fluid flow under varied ambient pressures were studied in comparison way. The lower ambient pressure plays an important role in deepening the keyhole by lower evaporation temperature of the material, higher laser energy density, and smaller laser beam refractive angle. The necking is easier to be reopened. Moreover, the laser energy distributes more uniformly on the keyhole wall at lower ambient pressure, giving rise to a smaller possibility for bubble formation. The ambient pressure also affects the shape and size of the molten pool as well as the distance and the viscosity of the zone that the bubble travels, which further influence the escape of bubbles. The modelling results of weld formation and pore defects are in the same trend as previous experimental data.

Similar content being viewed by others

References

Sun JH, Feng K, Zhang K, Guo BC, Jiang E, Nie PL, Huang J, Li ZG (2017) Fiber laser welding of thick AISI 304 plate in a horizontal (2G) butt joint configuration. Mater Des 118:53–65

Li SC, Chen GY, Zhou C (2015) Effects of welding parameters on weld geometry during high-power laser welding of thick plate. Int J Adv Manuf Technol 79(1–4):177–182

Sun DW, Cai Y, Wu Y, Zhu JJ, Wu YX (2014) Effect of external constraint on the characteristics and behavior of the plasma plume during high-power CO2 laser welding. Int J Adv Manuf Technol 73(9–12):1253–1263

Katayama S, Kobayashi Y, Mizutani M, Matsunawa A (2001) Effect of vacuum on penetration and defects in laser welding. J Laser Appl 13(5):187–192

Börner C, Krüssel T, Dilger K (2013) Process characteristics of laser beam welding at reduced ambient pressure. Proc. SPIE 8603, High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications II, 86030M (22 Feb. 2013); https://doi.org/10.1117/12.2003858

Cai C, Peng GC, Li LQ, Chen YB, Qiao L (2014) Comparative study on laser welding characteristics of aluminium alloy under atmospheric and subatmospheric pressures. Sci Technol Weld Join 19(7):547–553

Luo Y, Tang XH, Deng SJ, Lu FG, Chen QT, Cui HC (2016) Dynamic coupling between molten pool and metallic vapor ejection for fiber laser welding under subatmospheric pressure. J Mater Process Technol 229:431–438

Luo Y, Tang XH, Lu FG (2014) Experimental study on deep penetrated laser welding under local subatmospheric pressure. Int J Adv Manuf Technol 73(5–8):699–706

Kim J, Oh S, Son M, Ki H (2017) A study of keyhole behavior and weldability in zero-gap laser welding of zinc-coated steel sheets at subatmospheric pressures. J Mater Process Technol 249:135–148

Ki H, Mazumder J, Mohanty PS (2002) Modeling of laser keyhole welding: part I. Mathematical modeling, numerical methodology, role of recoil pressure, multiple reflections, and free surface evolution. Metall Mater Trans A 33(6):1817–1830

Ki H, Mazumder J, Mohanty PS (2002) Modeling of laser keyhole welding: part II. Simulation of keyhole evolution, velocity, temperature profile, and experimental verification. Metall Mater Trans A 33(6):1831–1842

Pang SY, Chen LL, Zhou JX, Yin YJ, Chen T (2010) A three-dimensional sharp interface model for self-consistent keyhole and weld pool dynamics in deep penetration laser welding. J Phys D Appl Phys 44:025301

Cho JH, Na SJ (2006) Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole. J Phys D Appl Phys 39:5372–5378

Zhang YX, Han SW, Cheon J, Na SJ, Gao XD (2017) Effect of joint gap on bead formation in laser butt welding of stainless steel. J Mater Process Technol 249:274–284

Pang SY, Hirano K, Fabbro R, Jiang T (2015) Explanation of penetration depth variation during laser welding under variable ambient pressure. J Laser Appl 27(2):022007

Wang CM, Lei B, Jiang P, Xu X, Mi GY (2018) Numerical and experimental investigation of vacuum-assisted laser welding for DP590 galvanized steel lap joint without prescribed gap. Int J Adv Manuf Technol 94(9–12):4177–4185

Fabbro R (2010) Melt pool and keyhole behaviour analysis for deep penetration laser welding. J Phys D Appl Phys 43(44):445501

Fabbro R, Dal M, Peyre P, Coste F, Schneider M, Gunenthiram V (2018) Analysis and possible estimation of keyhole depths evolution, using laser operating parameters and material properties. J Laser Appl 30(3):032410

Fabbro R, Chouf K (2000) Keyhole modeling during laser welding. J Laser Appl 87(9):4075–4083

Fabbro R, Hirano K, Pang SY (2016) Analysis of the physical processes occurring during deep penetration laser welding under reduced pressure. J Laser Appl 28(2):022427

Luo Y, Tang XH, Lu FG, Chen QT, Cui HC (2015) Spatial distribution characteristics of plasma plume on attenuation of laser radiation under subatmospheric pressure. Appl Opt 54(5):1090–1096

Anderson JD, Wendt J (1995) Computational fluid dynamics. Springer, Berlin

Hirt CW, Nichols BD (1981) Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys 39(1):201–225. https://doi.org/10.1016/0021-9991(81)90145-5

Jiang M, Tao W, Wang SL, Li LQ, Chen YB (2017) Effect of ambient pressure on interaction between laser radiation and plasma plume in fiber laser welding. Vacuum 138:70–79

Cho WI, Na SJ, Thomy C, Vollertsen F (2012) Numerical simulation of molten pool dynamics in high power disk laser welding. J Mater Process Technol 212(1):262–275

Chen Q, Tang XH, Lu FG, Luo Y, Cui HC (2015) Study on the effect of laser-induced plasma plume on penetration in fiber laser welding under subatmospheric pressure. Int J Adv Manuf Technol 78(1–4):331–339

Lin RQ, Wang HP, Lu FG, Solomon J, Carlson BE (2017) Numerical study of keyhole dynamics and keyhole-induced porosity formation in remote laser welding of Al alloys. Int J Heat Mass Tranf 108:244–256

Cho WI, Na SJ, Cho MH, Lee JS (2010) Numerical study of alloying element distribution in CO2 laser–GMA hybrid welding. Comput Mater Sci 49(4):792–800

Li XB, Lu FG, Cui HC, Tang XH, Wu YX (2014) Numerical modeling on the formation process of keyhole-induced porosity for laser welding steel with T-joint. Int J Adv Manuf Technol 72(1–4):241–254

Wu DS, Hua XM, Li F, Huang LJ (2017) Understanding of spatter formation in fiber laser welding of 5083 aluminum alloy. Int J Heat Mass Tranf 113:730–740

Kawaguchi I, Tsukamoto S, Arakane G and Nakata K (2006) Formation mechanism of porosity in deep penetration laser welding, Quarterly Journal of the Japan Welding Society, 24(4):338–343

Funding

This study is financially supported by the National Natural Science Foundation of China (No. 51675336).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, X., Tang, X., Wang, T. et al. Role of ambient pressure in keyhole dynamics based on beam transmission path method for laser welding on Al alloy. Int J Adv Manuf Technol 99, 1639–1651 (2018). https://doi.org/10.1007/s00170-018-2592-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2592-7