Abstract

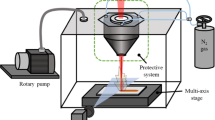

Under subatmospheric pressure, the influence of a plasma plume on weld penetration depth could be greatly improved in high-power laser welding. In this paper, a series of laser welding tests under different subatmospheric pressures were performed in a vacuum chamber. The dynamic images of the plasma plume were captured by a high-speed camera and analyzed. Based on the information extracted from the images, the variation of the plasma plume in gray level and spatial size were measured. For the whole plasma plume, the internal part plays a key role in the interaction with laser. So, the variation of brightness and size of the internal part were adopted as the characteristic parameters in describing the attenuation effect of laser caused by the plasma plume. Besides, a threshold value of pressure P cr, which is critical to the dramatic change of penetration, was found in the range of 10 to 20 kPa. As the ambient pressure was decreased to this critical range, the plasma plume was drastically shrunk, leading to a great reduction of absorption and refraction effect on laser and a resultant sharp increase of weld penetration.

Similar content being viewed by others

References

Chen HC, Pinkerton AJ, Li L (2011) Fibre laser welding of dissimilar alloys of Ti-6Al-4V and Inconel 718 for aerospace applications. Int J Adv Manuf Technol 52:977–987

Assunção E, Quintino L, Miranda R (2012) Comparative study of laser welding in tailor blanks for the automotive industry. Int J Adv Manuf Technol 49:123–131

Li CB, Liu LM (2013) Investigation on weldability of magnesium alloy thin sheet T-joints: arc welding, laser welding, and laser-arc hybrid welding. Int J Adv Manuf Technol 65:27–34

Arata Y, Abe N, Oda T (1985) Fundamental phenomena during vacuum laser welding. In: Proceedings of ICSLEO Materials Processing Symp, pp 1–7

Verwaerde A, Fabbro R, Deshors G (1995) Experimental study of continuous CO2 laser welding at subatmospheric pressures. J Appl Phys 78:2981–2984

Katayama S, Kobayashi Y, Mizutani M, Matsunawa A (2001) Effect of vacuum on penetration and defects in laser welding. J Laser Appl 13:187–192

Katayama S, Kawahito Y, Mizutani M (2010) Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys Procedia 5:9–17

Katayama S, Yohei A, Mizutani M, Kawahito Y (2011) Development of deep penetration welding technology with high brightness laser under vacuum. Phys Procedia 12:75–80

Jin XZ, Li LJ, Zhang Y (2002) A study on fresnel absorption and reflections in the keyhole in deep penetration laser welding. J Phys D Appl Phys 35:2304

Luo Y, Tang XH, Lu FG (2014) Experimental study on deep penetrated laser welding under local subatmospheric pressure. Int J Adv Manuf Technol 1–8

Li GH, Cai Y, Wu YX (2009) Stability information in plasma image of high-power CO2 laser welding. Opt Lasers Eng 47:990–994

Gao JQ, Qin GL, Yang JL, He JG, Zhang T, Wu CS (2011) Image processing of weld pool and keyhole in Nd: YAG laser welding of stainless steel based on visual sensing. Trans Nonferrous Metals Soc China 21:423–428

Bohren CF, Huffman DR (2008) Absorption and scattering of light by small particles. Hoboken, New York

Beck M, Berger P, Hugel H (1995) The effect of plasma formation on beam focusing in deep penetration welding with CO2 lasers. J Phys D Appl Phys 28:2430

Szymański Z, Kurzyna J (1994) Spectroscopic measurements of laser induced plasma during welding with CO2 laser. J Appl Phys 76:7750–7756

Tix C, Gratzke U, Simon G (1995) Absorption of the laser beam by the plasma in deep laser beam welding of metals. J Appl Phys 78:6448–6453

Poueyo-Verwaerde A, Fabbro R, Deshors G, De Frutos AM, Orza JM (1993) Experimental study of laser-induced plasma in welding conditions with continuous CO2 laser. J Appl Phys 74:5773–5780

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Q., Tang, X., Lu, F. et al. Study on the effect of laser-induced plasma plume on penetration in fiber laser welding under subatmospheric pressure. Int J Adv Manuf Technol 78, 331–339 (2015). https://doi.org/10.1007/s00170-014-6634-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6634-5