Abstract

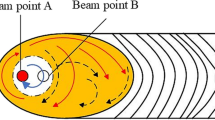

Improving of K-TIG welding process with a cusp magnetic field was experimentally tested. A cusp magnetic field setup was designed with water-cooled permanent magnetic poles. Stationary welding experiments were carried out to test the influence of magnetic field to the arc shape. Bead-on-plate welding processes were carried out to test the influence of magnetic field to the arc voltage and weld shape. Keyhole exit image sequence was captured with a vision system. It was found that, in the magnetic-enhanced K-TIG welding process, (1) the arc was constrained and changed into oval shape; (2) arc voltage was increased, front weld was narrowed and backside weld was widened; (3) keyhole exit shape also changed; (4) threshold current for fully penetrated keyhole was decreased and (5) the stainless steel weld microstructure experienced invisible change. The results show that the cusp magnetic field is feasible to improve the K-TIG arc behaviour and reduce the heat input.

Similar content being viewed by others

References

Schnick M, Fuentes JE, Zschetzsche J, Fussel U, Schuster H, Krink V, Huebner M, Szczesny M (2010) Cathode focussed TIG—fundamentals and applications. 63rd International Conference of the International Institute of Welding, Istanbul

Jarvis BL (2001) Keyhole gas tungsten arc welding—a new process variant. PHD thesis in The University of Wollongong, Australia

Feng YQ, Luo Z, Liu ZM, Li Y, Luo YC, Huang YX (2015) Keyhole gas tungsten arc welding of AISI 316L stainless steel. Mater Des 85:24–31

Lathabai S, Jarvis BL, Barton KJ (2001) Comparison of keyhole and conventional gas tungsten arc welds in commercially pure titanium. Mater Sci Eng A 299:81–93

Lathabai S, Jarvis BL, Barton KJ (2008) Keyhole gas tungsten arc welding of commercially pure zirconium. Sci Technol Weld Join 13(6):573–581

Liu ZM, Fang YX, Cui SL, Yi S, Qiu JY, Jiang Q, Liu WD, Luo Z (2017) Keyhole thermal behavior in GTAW welding process. Int J Therm Sci 114(4):352–362

Cui SL, Liu ZM, Luo Z, Fang YX, Manladan SM, Yi S (2017) Keyhole process in K-TIG welding on 4 mm thick 304 stainless steel. J Mater Process Technol 243(5):217–228

Liu ZM, Cui SL, Luo Z, Zhang CZ, Wang ZM, Zhang YC (2016) Plasma arc welding: process variants and its recent developments of sensing, controlling and modeling. J Manuf Process 23:315–327

José C (1981) Plasma-jets in arc welding. PHD Thesis in Massachusetts Institute of Technology

Fang YX, Liu ZM, Cui SL, Zhang Y, Qiu JY, Yi S, Luo Z (2017) Improving Q345 weld microstructure and mechanical properties with high frequency current arc in keyhole mode TIG welding. J Mater Process Technol 250(12):280–288

Zhang SB, Zhang YM (2000) Stability of keyhole in plasma arc welding. Proc Inst Mech Eng B J Eng 214:401–405

Slee B (1979) The economies of NWI plasma arc cutting. Metal Constr 11(10):549–553

Buerkner G (1993) Welding torch for dual gas shielded welding-with interrupted male thread on inner for female thread on outer torch. DD214318–A

Zhang JH, Wang QL, Song WP (1990) A study of the characteristics of magnetic control for low current TIG welding. Trans China Weld Inst 11(1):43–49

Yoshiaki A, Hiroshi M (1972) Magnetic control of plasma arc welding. Trans JWRI 1(1):1–9

Nomura K, Morisaki K, Hirata Y (2009) Magnetic control of arc plasma and its modelling. Weld World 53:R181–R187

Yao Q, Luo Z, Li Y, Yan FY, Duan R (2014) Effect of electromagnetic stirring on the microstructures and mechanical properties of magnesium alloy resistance spot weld. Mater Des 63:200–207

Curiel FF, García R, López VH, González-Sánchez J (2011) Effect of magnetic field applied during gas metal arc welding on the resistance to localised corrosion of the heat affected zone in AISI 304 stainless steel. Corros Sci 53(7):2393–2399

Lancaster JF (1986) The physics of welding. Pergamon, New York

Liu ZM, Fang YX, Cui SL, Luo Z, Liu WD, Liu ZY, Jiang Q, Yi S (2016) Stable keyhole welding process with K-TIG. J Mater Process Technol 238:65–72

Liu ZM, Wu CS, Chen MA (2014) Experimental sensing of the keyhole exit deviation from the torch axis in plasma arc welding. Int J Adv Manuf Technol 71:1209–1219

Zhao PS, Zhu SY, Zhao GH (1986) Physical features and welding characteristics of a plasma arc re-constricted by a dual-cusp magnetic field. Trans China Weld Inst 7(1):7–14

Funding

Financial support for this research was from the National Natural Science Foundation of China (No. 51505329), Tianjin Research Program of Application Foundation and Advanced Technology (No. 15JCQNJC03400) and Natural Science Foundation of Jiangsu Province of China (General Program, No. BK20161475); the research is also supported by State Key Lab of Advanced Welding and Joining, Harbin Institute of Technology and Tianjin University.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Z., Chen, S., Yuan, X. et al. Magnetic-enhanced keyhole TIG welding process. Int J Adv Manuf Technol 99, 275–285 (2018). https://doi.org/10.1007/s00170-018-2501-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2501-0