Abstract

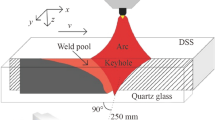

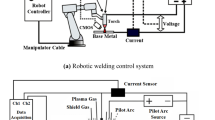

Sensing the dynamic behavior of the keyhole is of great significance to control and ensure the process quality and the resultant weld quality in plasma arc welding (PAW). Usually, the keyhole size is used as the geometric features describing the keyhole status. In this study, it is first found that the keyhole exit is displaced in the direction opposite to the welding direction even at the low welding speed during the PAW process. To examine the correlation of the keyhole exit deviation and the process parameters, the developed cost-effective vision sensor is used to observe the keyhole exit at the backside of the stainless steel workpieces with medium thickness. Based on the pre-processing and calibration of the captured sequential images of the keyhole, both the keyhole geometry and its position relative to the torch axis are determined under different test conditions. It is found that the deviation distance of the keyhole exit from the torch axis takes a larger value at first, then drops, and finally gets a fixed level, as the keyhole undergoes the initial blind stage, the unstable stage, and the quasi-steady stage. The effects of the main process parameters (welding current, welding speed, and plasma gas flow rate) on the deviation distance and the sizes of the keyhole exit are quantitatively analyzed. It is found that the deviation distance of the keyhole exit varies more obviously than the keyhole size as the welding process parameters changes within the appropriate ranges. The distortion of the thermal field on the workpiece due to the motion of the plasma arc and the inclination of the front keyhole wall are the main reason of the deviation occurrence.

Similar content being viewed by others

References

Kou S (2003) Welding metallurgy, 2nd edn. Wiley, New Jersey

Fortain JM (2008) Plasma welding evolution and challenges. Int Inst Weld Doc XII-1948:1–11

Lucas B (2008) Advances in arc welding processes and equipment. In: Hirata Y, Tanaka M (eds) Proc. of the 8th International Welding Symposium, Kyoto, Japan, pp. 189–190

Zhang SB, Zhang YM (2000) Stability of keyhole in plasma arc welding. Proc IME B J Eng Manufact 214:401–405

Fan HG, Kovacevic R (1999) Keyhole formation and collapse in plasma arc welding. J Phys D Appl Phys 32:2902–2909

Martikainen JK, Moisio TJI (1993) Investigation of the effect of welding parameters on weld quality of plasma arc keyhole welding of structural steels. Weld J 82:329s–340s

Wu CS, Jia CB, Chen MA (2010) A control system for keyhole plasma arc welding of stainless steel with medium thickness. Weld J 89:225s–231s

Steffens HD, Kayser H (1972) Automatic control for plasma arc welding with constant keyhole diameter. Weld J 51:408–418

Zhang SB, Zhang YM (2001) Efflux plasma charge-based sensing and control of joint penetration during keyhole plasma arc welding. Weld J 80:157s–162s

Saad E, Wang H, Kovacevic R (2006) Classification of molten pool modes in variable polarity arc welding based on acoustic signature. J Mater Process Technol 174:127–136

Chen Q, Sun ZG, Sun JW, Wang YW (2004) Closed-loop control of welding penetration in keyhole plasma arc welding. Trans Nonferrous Metals Soc China 14:116–120

Dong CL, Zhu YF, Zhang H, Shao YC (2001) Study on front side arc light sensing in keyhole mode plasma arc welding. Chin J Mech Eng 37:30–33

Zhang YM, Ma Y (2001) Stochastic modeling of plasma reflection during keyhole arc welding. Meas Sci Technol 12:1964–1975

Zhang YM, Zhang SB, Liu YC (2001) A plasma cloud charge sensor for pulse keyhole process control. Meas Sci Technol 12:1365–1370

Zhang WJ, Liu YK, Wang X, Zhang YM (2012) Characterization of three-dimensional weld pool surface in gas tungsten arc welding. Weld J 91:195s–203s

Gu WP, Xiong ZY, Wan W (2013) Autonomous seam acquisition and tracking system for multi-pass welding based on vision sensor. Int J Adv Manuf Technol 69:451–460

Wu CS, Zhong LM, Gao JQ (2009) Visualization of hump formation in high speed gas metal arc welding. Meas Sci Technol 20:115702

Moon HS, Kim YB, Beattie RJ (2006) Multi sensor data fusion for improving performance and reliability of fully automatic welding system. Int J Adv Manuf Technol 28:286–293

Huang HS, Xiao YL, Wang PJ, Li MZ (2013) A seam-tracking laser welding platform with 3D and 2D visual information fusion vision sensor system. Int J Adv Manuf Technol 67:415–426

Fujinage S, Takenaka H, Narikiyo T, Katayama S, Matsunawa A (2000) A direct observation of keyhole behavior during pulse modulated high-power Nd:YAG laser irradiation. J Phys D Appl Phys 33:492–497

Fabbro R, Sliman S, Coste F, Briand F (2005) Study of keyhole behavior for full penetrated Nd–YAG CW laser welding. J Phys D Appl Phys 38:1881–1887

Liu ZM, Wu CS, Gao GJ (2013) Vision-based observation of keyhole geometry in plasma arc welding. Int J Therm Sci 63:38–45

Lancaster JF (1986) The physics of welding. Pergamon, New York

Matsunawa A, Semak V (1997) The simulation of front keyhole wall dynamics during laser welding. J Phys D Appl Phys 30:798–809

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Z.M., Wu, C.S. & Chen, M.A. Experimental sensing of the keyhole exit deviation from the torch axis in plasma arc welding. Int J Adv Manuf Technol 71, 1209–1219 (2014). https://doi.org/10.1007/s00170-013-5568-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5568-7